INSTALLATION AND LOCATION

When locating your CDG Series dispenser, convenience and accessibility to best serve your

operation are important considerations, but the following factors must be observed:

Counters, platforms, or shelves should be strong enough to support the dispenser and full

containers of product. Refer to the minimum weight specification of your particular model of

dispenser. This is the weight of the empty dispenser.

The dispenser requires 3”(75mm) of clearance on either side, as well as a 6” (150mm) clearance

on the top. Do not place items on top of the dispenser. Inadequate clearance or covering the

top vents will significantly reduce system efficiency and cause damage to the compressor.

There are no space requirements for the rear of the CDG Series dispenser.

The dispenser must be placed onto a level surface.

Avoid placing the dispenser too close to a heat source, such as a coffee maker. This would affect

the performance of the unit.

Place the dispenser at the appropriate serving height so that staff drawing product from the

dispenser can operate the unit properly.

Do not remove the legs from the dispenser or allow the dispenser to sit flat on the counter.

Airflow and circulation under the machine are essential for the proper operation of the

refrigeration system. Make sure the legs at the four corners of the bottom of the dispenser are

in place. If one has loosened during shipping, re-tighten it. Removal of the legs automatically

voids the Warranty.

Before starting the dispenser, make certain that all Installation instructions have been followed

and that the dispenser has been sitting upright for a minimum of 3 hours, to allow the

compressor oil to settle.

Connect the power cord into an approved electrical outlet.

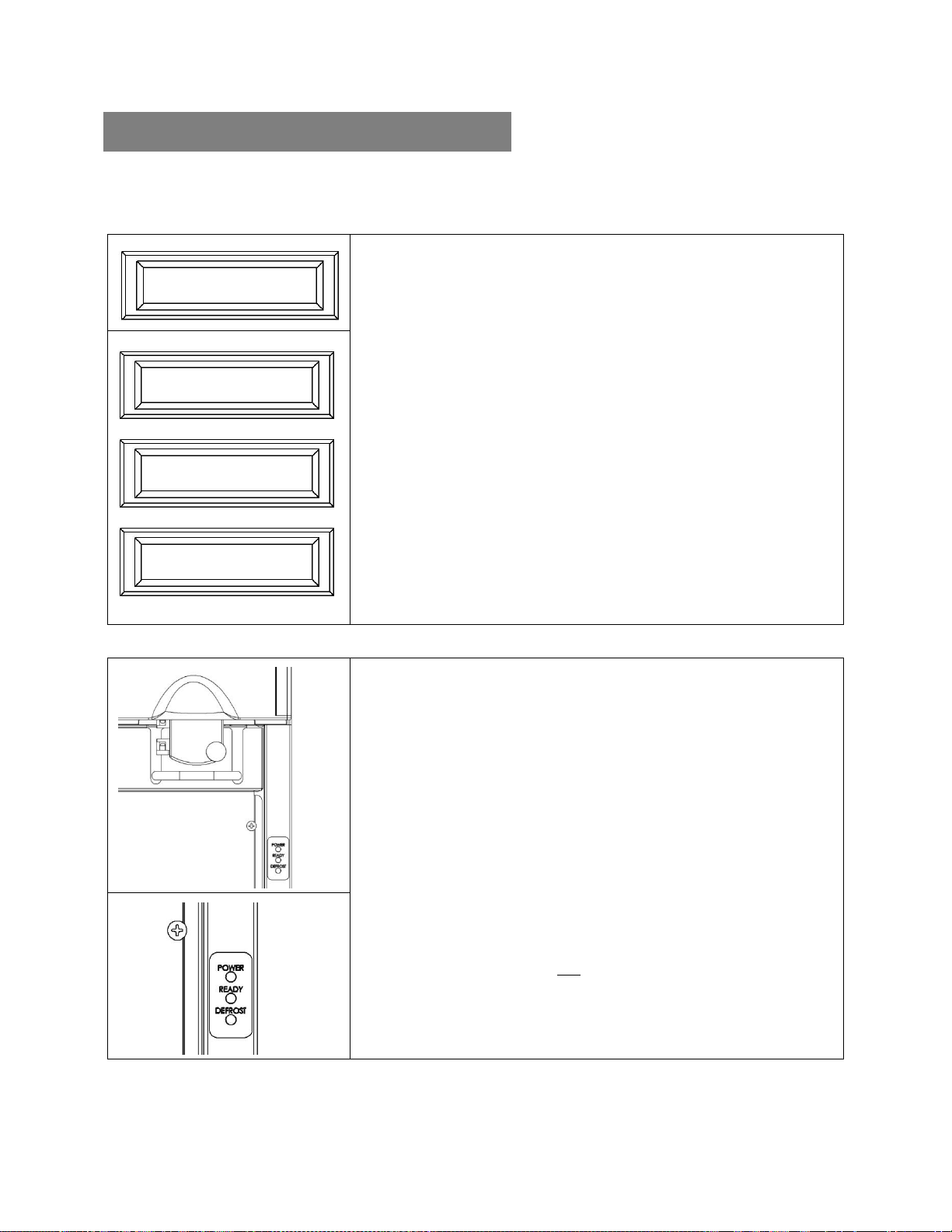

Activate the control system and refrigeration by switching ON the power control switch.

Power can be confirmed by the following (as applicable):

oLCD will indicate “Always Fresh”;

oPower LED will illuminate green;

oBacklit door display will illuminate.

The temperature control has been pre-set at the factory. Allow the dispenser to run

empty for one hour before loading pre-chilled product. Compartment temperature is

confirmed by the following (as applicable):

oLCD will indicate compartment temperature of 32°F to 40°F (0°C to 5°C);

oReady LED will illuminate green;

oInterior compartment thermometer will indicate 32°F to 40°F (0°C to 5°C).

Locate the Drip Tray and install the Bag-In-Box Shelf (or optional accessory).

Load pre-chilled KanPak product of your choice, as instructed.

Close the dispenser door and secure latch.