2 – 3 HP J SERIES FOUNTAIN MANUAL

884168 / 2021.1.1

2

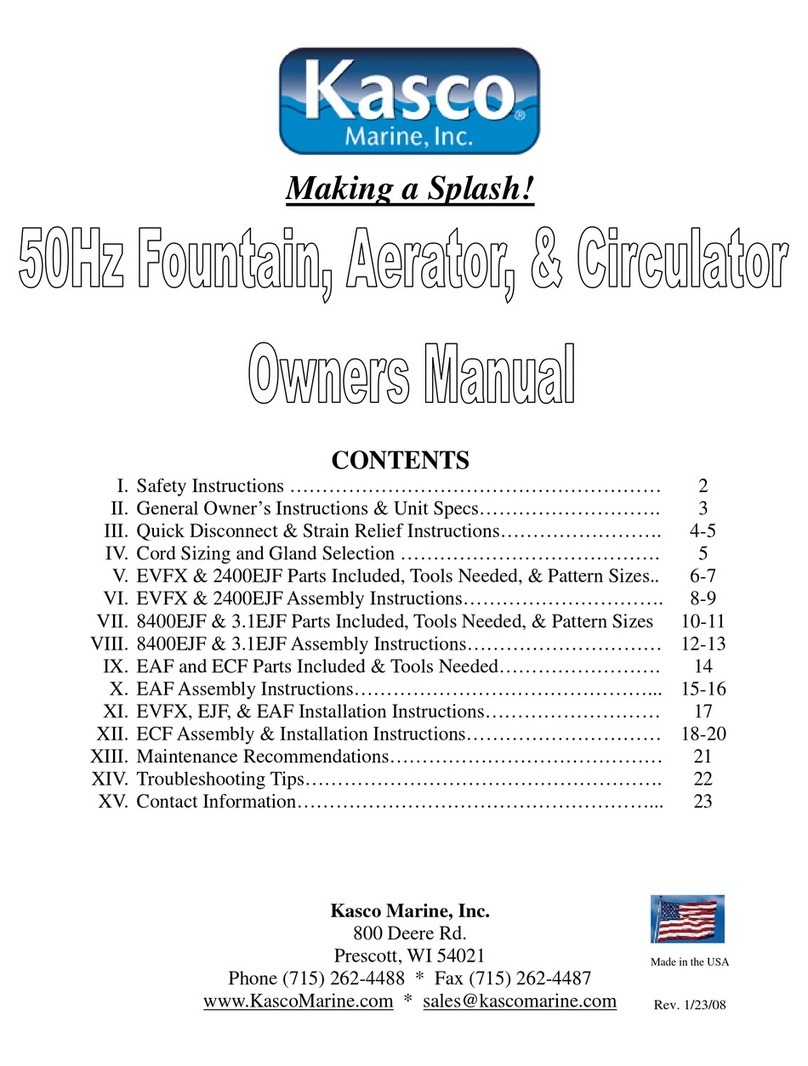

Contents

Important Safety �����������������������������������������������2

Tools and Supplies Needed������������������������������3

Unit Specs ��������������������������������������������������������3

Parts Included���������������������������������������������������4

Nozzles Included ����������������������������������������������5

Premium Nozzles (Not Included)����������������������6

Assembly Instructions���������������������������������������7

IMPORTANT SAFETY

• Please read and follow these important instructions to help ensure your safety and the quality performance of your Kasco equip-

ment�

• Use caution when dealing with any electrical and/or moving equipment�

• Under NO CIRCUMSTANCE should anyone enter the water with the electrical equipment plugged in and/or in operation�

• Kasco Aerating Fountains are intended for use with a Listed control panel having a GFCI protected receptacle, or eld wiring

terminals and disconnect switch, or a timer with a disconnect for use with a GFCI receptacle� Control panels MUST be installed by

a qualied electrician. Ground Fault Circuit Interrupters (GFCIs) should be tested upon each installation and every month thereafter

to ensure proper operation�

• Single-phase units are supplied with an internal grounding conductor and/or a grounding-type attachment plug� To reduce the risk

of electrical shock, be certain the unit is properly connected to the Kasco-supplied control panel (refer to the instructions included

with your control panel)�

• 3-phase units (2�3JF, 3�3JF, 5�3JF, 7�3JF, 2�3HJF, 3�3HJF, 5�3HJF, 7�3HJF) require a startup test after wiring to ensure proper

rotation of the impeller� If the impeller is rotating in the opposite direction, the unit will not perform properly and internal damage to

the unit may occur (see 3-phase startup procedure on page 12)�

• NEVER run the unit out of the water� This will damage the seals and create a dangerous situation for the operator�

• Use extreme caution around water, especially cold water, as in Spring, Fall, and Winter, which poses a hazard in and of itself�

• NEVER lift or drag the equipment by the power cords� If you need to pull the unit to the side of the pond, use the anchoring ropes�

• Do not use boats that tip easily for installation and follow all boating safety rules and regulations, including wearing a PFD (Person-

al Flotation Device)� Do not use waders in deep ponds/lakes or ponds/lakes with drop-offs, drastic slopes, or soft bottom material�

• For more information regarding your control panel instructions, refer to your control panel owner’s manual� A control panel must be

Nozzle Installation Instructions�����������������������10

Unit Installation Instructions����������������������������11

3-Phase Startup Procedure����������������������������12

Repair�������������������������������������������������������������14

Non-Warranty Repairs������������������������������������15

Troubleshooting Tips ��������������������������������������16

Repair Contact Form ��������������������������������������17

This Kasco product is the result of years of innovation, and we are condent that

you will be impressed with its quality and performance� If you have any questions

about assembly, installation, or maintenance, please reach out to our friendly and

knowledgeable customer care team� Thank you for trusting Kasco�