System Description

The Katadyn PowerSurvivor 80E watermaker system has several components. Refer to the

System Diagram (Figure A-1) in the Appendix for an overview of the components of the system

and their interconnections.

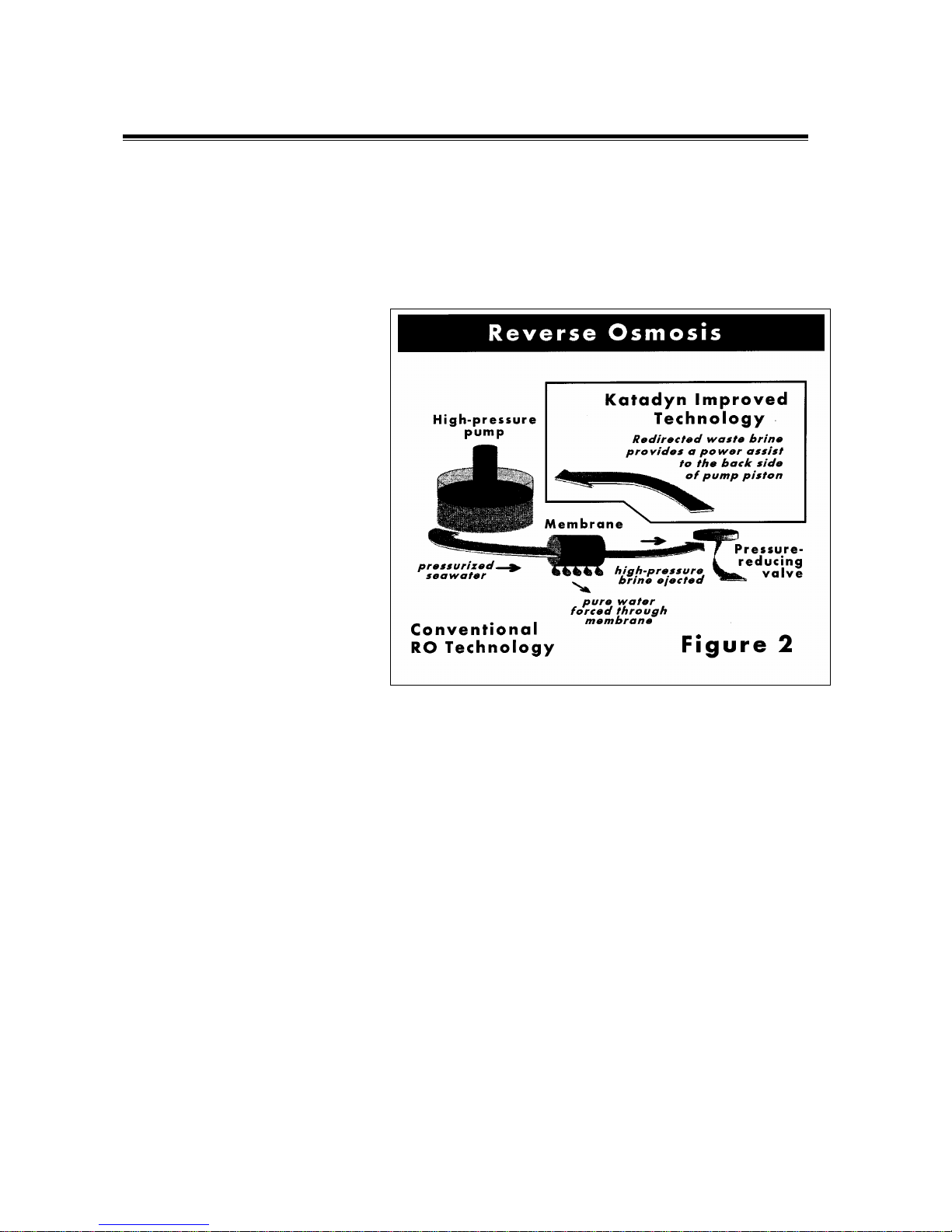

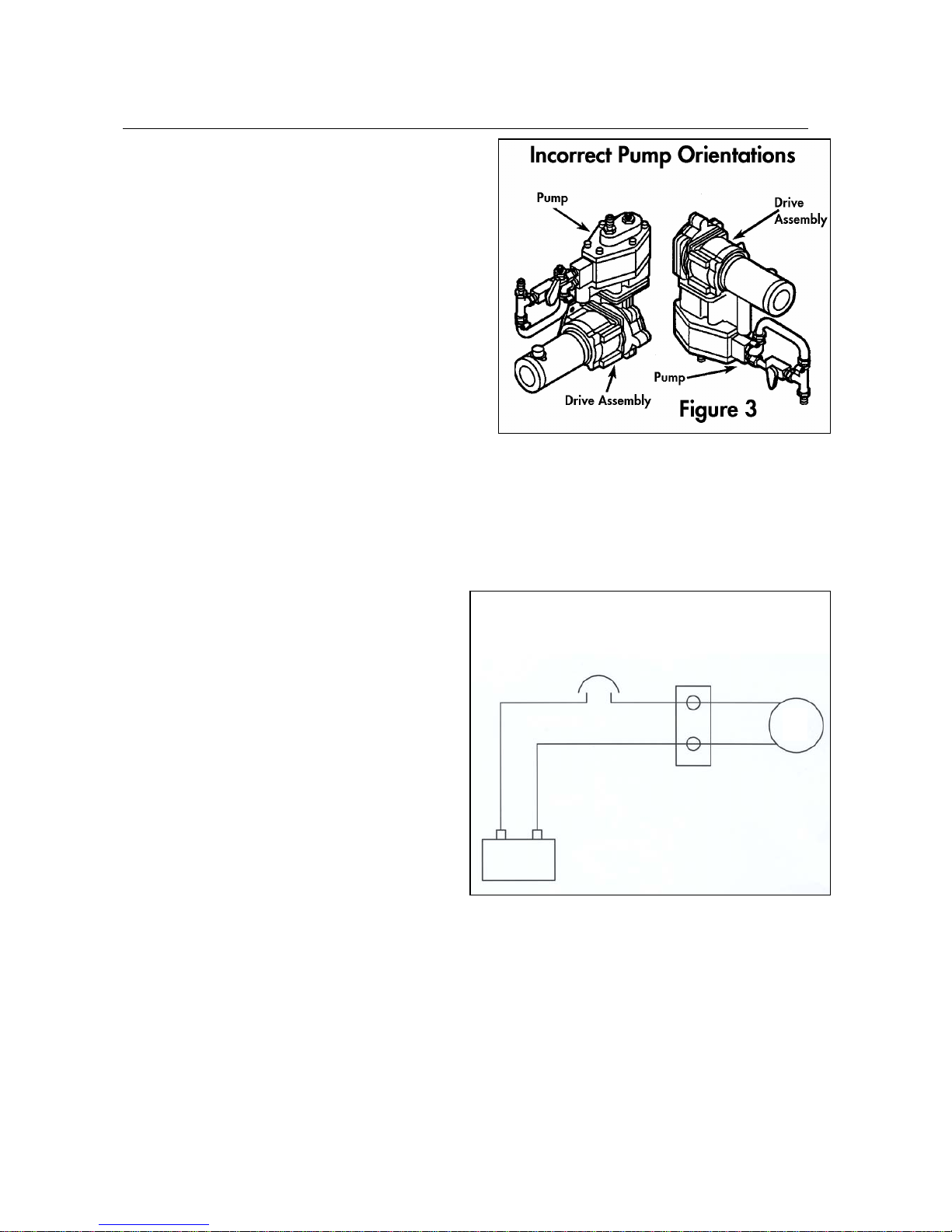

Motor/Drive/Pump & Membrane Housing: At the heart of the watermaker system

is a high-pressure, positive-displacement pump. The pump is powered by a reliable 12 (or 24)

VDC electric motor. An oil-bath gearbox (drive assembly) converts the rotary motion of the

electric motor to a powerful, reciprocating, linear motion for driving the pump piston. The pump

pressurizes input seawater to approximately 800 psi (pounds per square inch) and forces

product freshwater through a semipermeable membrane located in the membrane housing. The

motor, gearbox and pump have been integrated into a single, compact piece of equipment—

with low power consumption, quiet operation and a small footprint. The membrane assembly is

a separate unit which allows it to be mounted in a convenient location.

Prefilter Assembly: The prefilter assembly consists of one prefilter housing and a

standard 30-micron prefilter element constructed of polyester fibers. Two standard elements

ship with each system. In some exceptional circumstances, an optional second prefilter

assembly with a 5-micron prefilter element may be needed (see Kits & Accessories). The

prefilter assembly is separate unit which allows it to be installed in a convenient and accessible

location.

Valves: Two high-quality plastic 3-way valves are supplied. The prefilter 3-way valve selects

between (1) seawater input for normal operation and (2) an alternate intake line for inputting

membrane preservative or a cleaning solution. The product 3-way valve allows easy routing of

product water to either (1) a freshwater collection tank for normal operation or (2) a drain

location for discarding during initial startup, testing, preservation or cleaning operations.

Hoses and Hardware: Each PowerSurvivor 80E watermaker is shipped with appropriate

hoses and hardware sufficient to perform a normal installation. This includes two high-pressure

hoses (3’ and 5’) for carrying pressurized seawater from the pump to the membrane housing

and reject brine water from the membrane housing back to the pump. The 1/2" I.D. reinforced

plastic hose is used for seawater intake and reject brine. The smaller, 1/4" I.D. clear plastic

hose is for routing product freshwater. There are also hose clamps and mounting bracket

hardware for the prefilter assembly and membrane housing, and a TDS (Total Dissolved Solids)

meter for testing and monitoring the quality of product freshwater.

Customer-supplied Equipment: Every installation represents a unique challenge!

You or your installer will need to provide:

1. a reliable source of clean seawater for input to the prefilter 3-way valve

2. plumbing to an appropriate drain location for the reject brine water

3. a plumbing solution for your freshwater collection tank

Our Promise: Every Katadyn PowerSurvivor 80E watermaker includes a three-year factory

warranty and a long history of outstanding customer support. Our reputation for providing a

quality product, along with service when and where you need it, is unequaled in the industry. Of

course, you may never need us—but, if you do, we’ll be there.

1