TRIGA TR-B200SR-WH User manual

TR-B200SR-WH, TR-B200SR-IV

Intelligent Sounder Base

INSTALLATION AND MAINTENANCE INSTRUCTIONS

BEFORE INSTALLING

Read System Sensor’s Applications Guide for System Smoke Detectors

(SPAG91), which provides detailed information on sensor spacing, placement,

zoning, wiring, and special applications. This manual is available online at

www.systemsensor.com. NFPA 72 and NEMA guidelines should be observed.

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector used with this base must be tested and maintained

regularly following NFPA 72 requirements. The detector should be cleaned at

least once a year.

GENERAL DESCRIPTION

The TR-B200SR-WH and TR-B200SR-IV sounder bases are used with address-

able detector heads. Refer to the appropriate manual for more information on

sensors.

The TR-B200SR-WH and TR-B200SR-IV sounder bases were designed specifi-

cally to meet the needs of dwelling unit applications. It offers maximum flex-

ibility in configuration and operation to meet or exceed the requirements of

UL268 and UL464.

The sounder base is capable of producing either the distinctive three-pulse

temporal pattern (ANSI Temporal 3) fire alarm signal now required by NFPA

72 for commercial and residential applications or a continuous tone by simply

removing the included jumper from the device.

The sounder base is intended for use with intelligent systems. The sounder

base requires an external 24 VDC power supply. The connections for the

external power supply and the communication loop are isolated to prevent

electrical interaction between them. Refer to the panel manual for maximum

allowable number of units per loop.

NOTE: For NFPA72 Installations, the Temporal 3 tone should be used for pub-

lic mode evacuation.

NOTE: When not used as a supplementary evacuation system, the external 24

VDC supply shall be treated as a component of the main power supply system

and shall fall under the requirements of the main power supply system per

NFPA 72.

WIRING GUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and the local codes having jurisdiction and must not be of such length or wire

size which would cause the base to operate outside of its published specifica-

tions. The conductors used to connect smoke sensors to control panels and

accessory devices should be color coded to reduce the likelihood of wiring

errors. Improper connections can prevent a system from responding properly

in the event of a fire.

Specifications

Base Diameter: 6.875" (17.46 cm)

Base Height (less sensor): 2.0" (5.08 cm)

Weight: 0.50 lb. (227 gm)

Operating Temperature Range: Refer to the applicable sensor’s operating temperature range provided in the sensor’s installation manual.

Operating Humidity Range: 10% to 93% relative humidity (non-condensing)

External Supply Electrical Ratings

External Supply Voltage: 16 to 33 VDC (VFWR)

Standby Current: 500 μA maximum

Alarm Current: 35 mA maximum

SLC Electrical Ratings

SLC Operating Voltage: 15 to 32 VDC

SLC Standby Current: 300 μA maximum

Sound Output Greater than 85 dBA minimum measured in a UL reverberant room at 10 feet (3.1m), 24 Volts (in continuous tone)

Wire sizes up to 12 AWG (2.5 mm2) may be used with the base. The sounder

base will be shipped with the screw terminals set for 14 AWG wiring. If

12 AWG wire is to be used, back out the screws to allow the wire to fit beneath

the clamping plates. For best system performance, the power (+ and -) wires

and the communication circuit wires should be twisted pair or shielded cable

installed in a separate grounded conduit to protect the communication loop

from electrical interference.

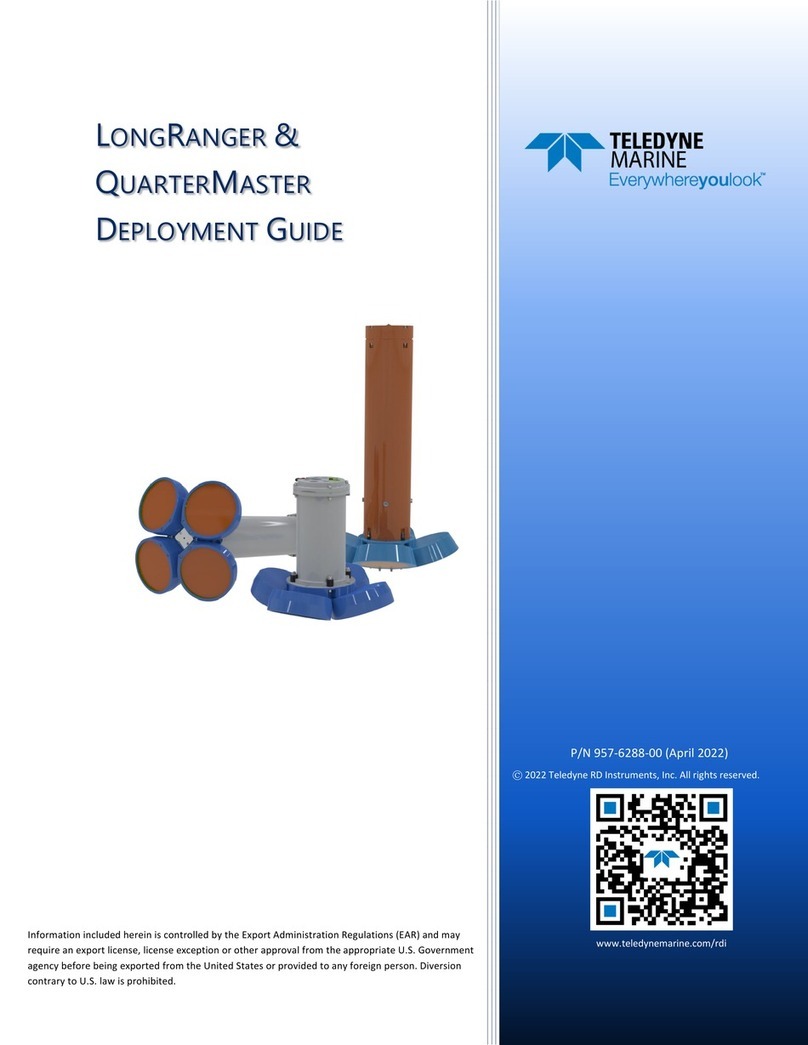

Make wire connections by stripping about 3

/8" (10 mm) of insulation from the

end of the wire. Then, slide the bare end of the wire under the appropriate

clamping plate (See Figure 1), and tighten the clamping plate screw. Do NOT

loop the wire under the clamping plate. (See Figure 2.) The wiring diagram for

a typical 2-wire intelligent system is shown in Figure 5.

CAUTION

For system monitoring - for terminals 4 and 5, do not use looped wire under termi-

nals. Break wire run as shown in Figure 2 to provide monitoring of connections.

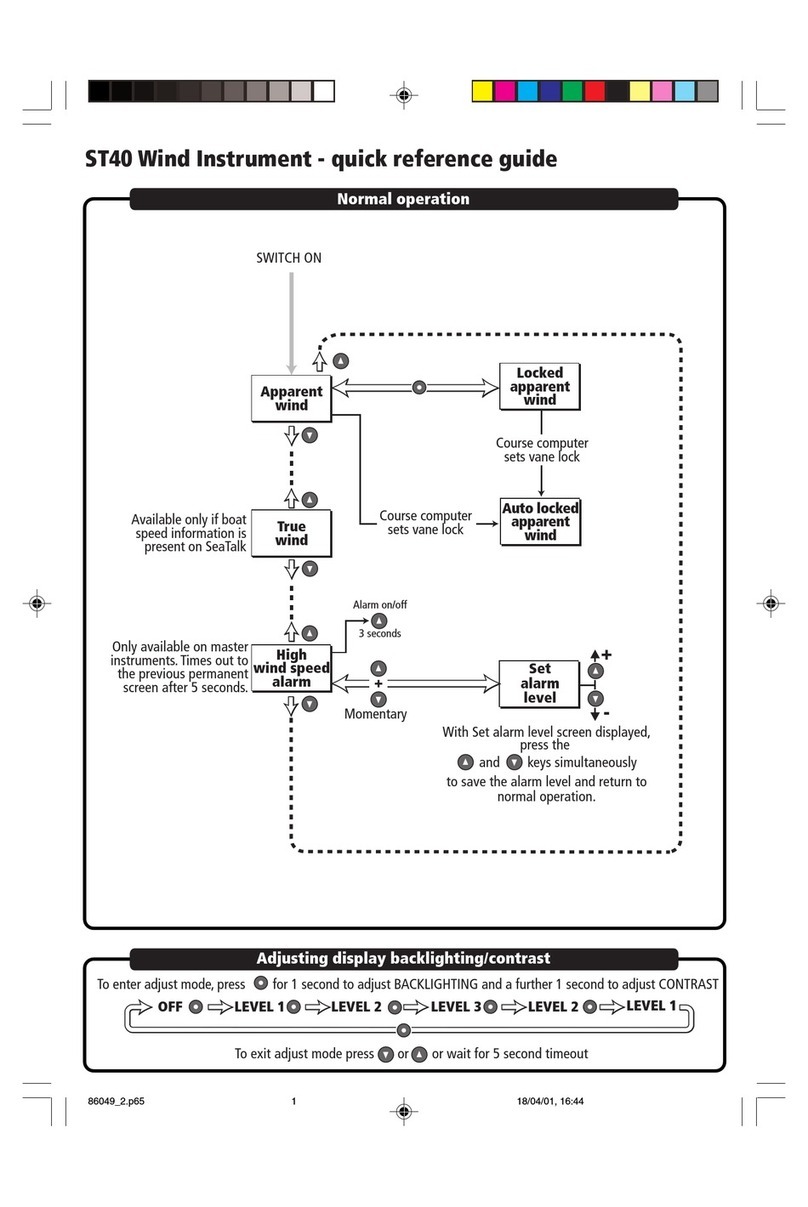

FIGURE 1. FIGURE 2.

1

1

2

2

3

3

4

4

5

5

6

6

C0471-07 C0473-00

TR-B200SR-WH/TR-B200SR-IV TERMINALS

No. Function

1. Not Used

2. Positive (+) Comm. Line In and Out

3. Negative (-) Comm. Line In and Out

4. External Supply Positive (+)

5. External Supply Negative (-)

6. Sounder Base Interconnect

TRIGA Life Safety Systems, LLC

7600 Olde Eight Rd.

Hudson, Ohio 4426-1057

I56-3392TRG-011

base/sensor cross reference chart ==>base/sensor cross reference chart ==>

Source:

For a list of compatible sensors, refer to the Sys-

tem Sensor website at www.systemsensor.com.

1/29/2021

For a complete list of compatible sensors, refer to

the Base/Sensor Cross Reference Chart at triga-

global.com.

4/23/2021 DELETE: For a complete list of compat-4/23/2021 DELETE: For a complete list of compat-

ible bases, refer to the Base/Sensor Cross Referenceible bases, refer to the Base/Sensor Cross Reference

Chart at trigaglobal.com.Chart at trigaglobal.com.

1 I56-3392TRG-011

4/22/2021

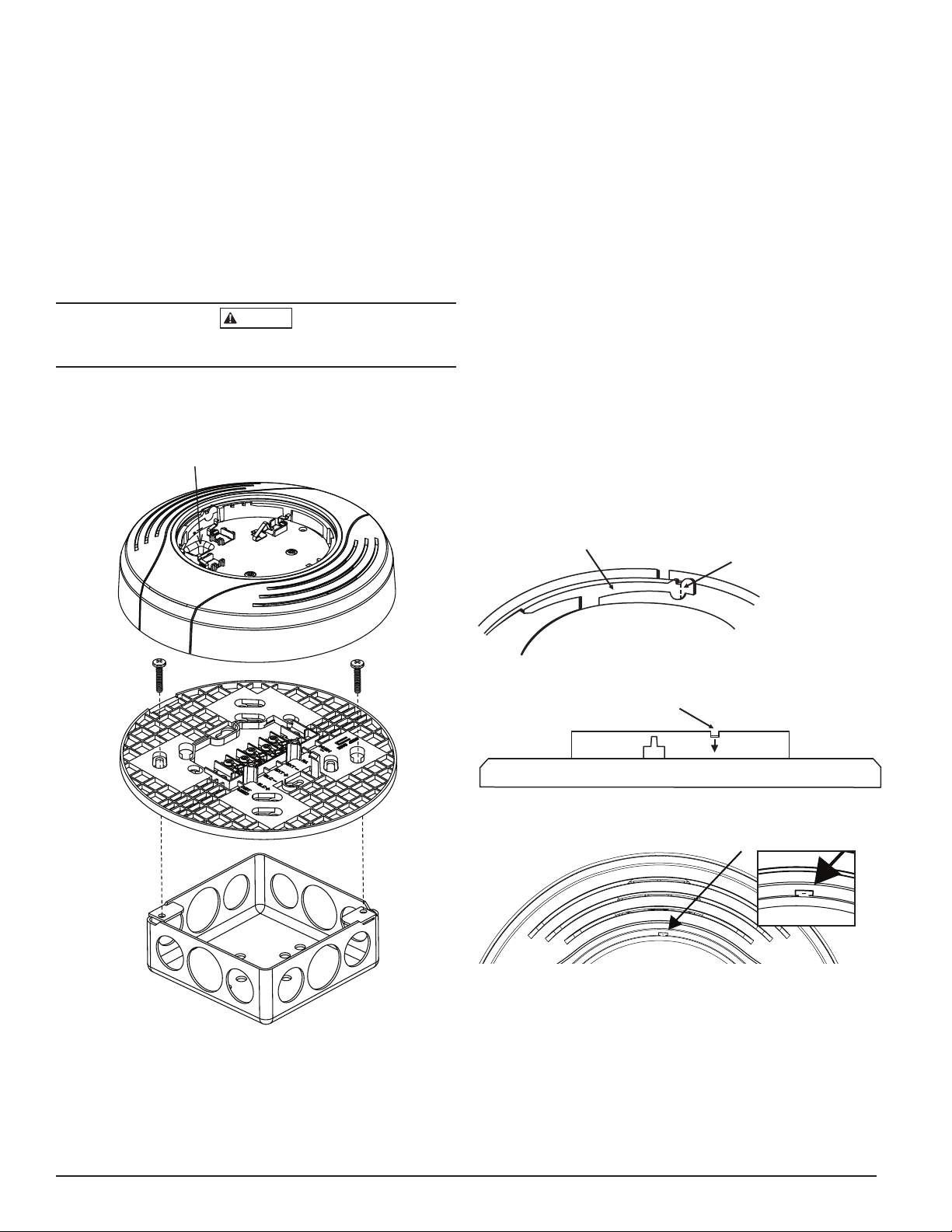

MOUNTING

Mount the TR-B200SR-WH/TR-B200SR-IV mounting plate directly to an elec-

trical box. The plate will mount directly to 4" (10.2cm) square (with and with-

out plaster ring), 4" (10.2cm) octagon, 3½" (8.9 cm) octagon, single gang or

double gang junction boxes.

1. Connect field wiring to terminals, as shown in Figure 1 and 2.

2. Attach the mounting plate to the junction box as shown in Figure 3.

3. To mount the sounder base, hook the tab on the sounder base to the groove

on the mounting plate.

4. Then, swing the sounder base into position to engage the pins on the

product with the terminals on the mounting plate.

5. Secure the sounder base by tightening the mounting screws.

6. Install a compatible smoke sensor as described in the installation manual

for the sensor.

CAUTION

Do not over tighten mounting plate screws; this may cause mounting plate

to flex.

FIGURE 3. MOUNTING

Location of jumper–

remove to enable

continuous tone

C0891-08

TAMPER RESISTANT FEATURE

NOTE: Do not use the tamper-resist feature if the removal tool is to be used.

This detector base includes a tamper-resist feature that prevents its removal

from the base without the use of a tool. To activate this feature, break the tab

from the detector base as shown in Figure 4A. Then, install the detector. To

remove the detector from the base once the tamper-resist feature has been ac-

tivated, insert a small-bladed screwdriver into the slot from the top and press

down on the lever. (See Figure 4B). This allows the detector to be rotated

counterclockwise for removal. The tamper-resist feature can be defeated by

breaking and removing the plastic lever from the base. However, this prevents

the feature from being used again.

TESTING AND MAINTENANCE

Sensors and bases must be tested after installation and as an integral part of

a periodic maintenance program. Test the TR-B200SR-WH/TR-B200SR-IV as

follows:

NOTE: Before testing, notify the proper authorities that the smoke sensor

system is undergoing maintenance and, therefore, will be temporarily out of

service. Disable the system undergoing maintenance to prevent unwanted

alarms.

1. If configured as in Figure 5 and 6, reverse the polarity of the external 24VDC

supply. If configured as in Figure 6, turn on the Intelligent Relay Module.

All TR-B200SR-WH/TR-B200SR-IV bases on the loop should sound.

2. Latch the sensor LED on from the control panel. That individual sensor’s

TR-B200SR-WH/TR-B200SR-IV should sound.

When performing maintenance on connected smoke sensors, carefully note

the location and address of each removed sensor.

FIGURE 4A. ACTIVATING THE TAMPER-RESIST FEATURE

PLASTIC LEVER

BREAK TAB AT

DOTTED LINE BY

TWISTING TOWARD

CENTER OF BASE.

C0144B-01

USE SMALL-BLADED

SCREWDRIVER TO

PUSH PLASTIC LEVER

IN DIRECTION OF

ARROW.

C0144B-01

FIGURE 4B. REMOVING THE DETECTOR HEAD FROM THE BASE

SLOT

SLOT

C1082-00

2 I56-3392TRG-011

4/22/2021

(+) SLC

(+) SLC

NO 1

NO 2

NC 2

COMM 2

COMM 1

NC 1

(–) SLC

(–) SLC

(–) POWER

(+) POWER

U.L. LISTED COMPATIBLE

CONTROL PANEL

OPTIONAL SOUNDER INTERCONNECT*

NOT

USED

SLC +

EXT –

EXT +

RA

SLC –

NOT

USED

SLC +

EXT –

EXT +

RA

SLC –

(+) SLC

(–) SLC

SUP (–)

SUP (+)

* GROUPING OF UP TO 6 MODEL TR-B200SR-WH (-IV) SOUNDER BASES

INTELLIGENT

MONITOR MODULE

INTELLIGENT

RELAY MODULE†

FIRST

SOUNDER

BASE

LAST

SOUNDER

BASE

†THIS IS A STANDARD RELAY

MODULE CONFIGURED TO

REVERSE THE POWER

UL LISTED

EOL

RESISTOR

47k

UL LISTED 24V

POWER SUPPLY

END OF LINE RELAY

(EOLR-1 OR

EQUIVALENT)

TO OPTIONAL REMOTE

ANNUNCIATOR

MODEL RA100Z

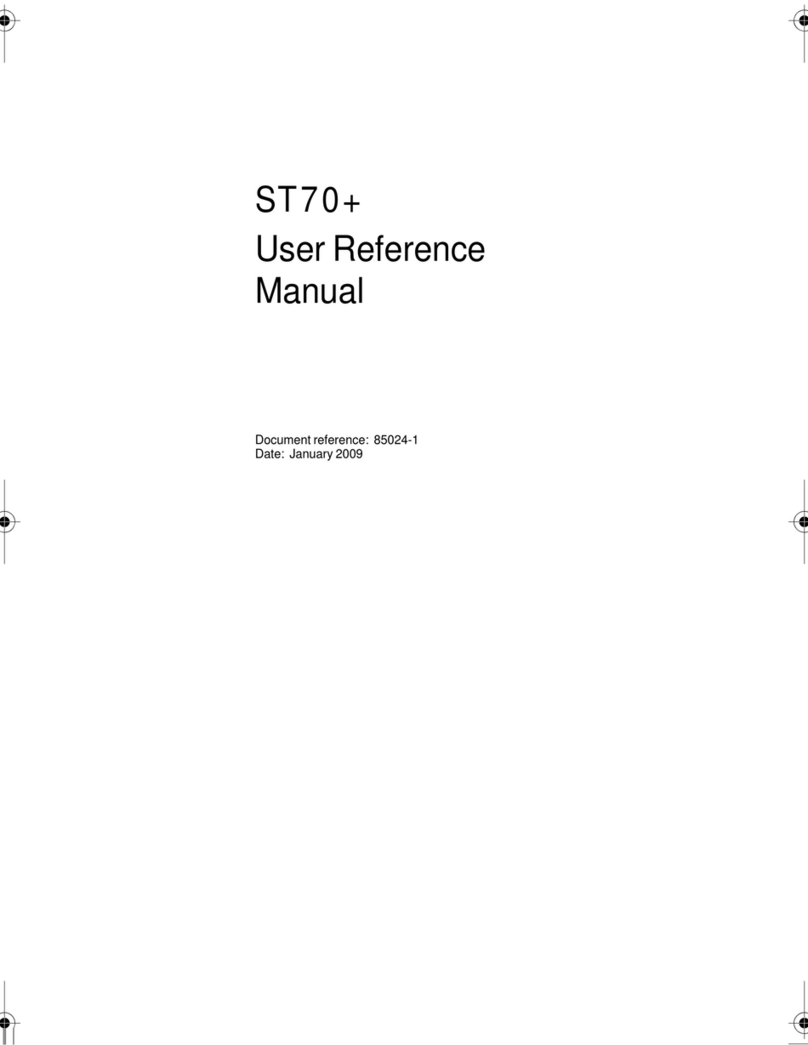

FIGURE 5. WIRING DIAGRAM

FIGURE 6. WIRING DIAGRAM

(+) SLC

(–) SLC

(–) POWER

(+) POWER

UL LISTED COMPATIBLE

CONTROL PANEL

OPTIONAL SOUNDER INTERCONNECT*

TO OPTIONAL REMOTE

ANNUNCIATOR

MODEL TR-RA100Z

CLASS A OPTIONAL WIRING

CLASS A OPTIONAL WIRING

NOT

USED

SLC +

EXT –

EXT +

RA

SLC –

NOT

USED

SLC +

EXT –

EXT +

RA

SLC –

(+) SLC

(–) SLC

SUP (–)

SUP (+)

* GROUPING OF UP TO 6 MODEL TR-B200SR-WH (-IV) SOUNDER BASES

INTELLIGENT

MONITOR MODULE

FIRST

SOUNDER

BASE

SECOND

SOUNDER

BASE

LAST

SOUNDER

BASE

UL LISTED

EOL

RESISTOR

47k

NOT

USED

SLC +

EXT –

EXT +

RA

SLC –

UL LISTED 24V

POWER SUPPLY

END OF LINE RELAY

(EOLR-1 OR

EQUIVALENT)

C0970TRG-22

C0970TRG-23

DETECTOR ACTIVATES SOUNDER BASE(S) - (COMPLIES WITH UL268)

UL has approved grouping for up to six TR-B200SR-WH/TR-B200SR-IV sounder bases. When wired as a group, any detector in the group that has been activated

by the panel will cause other TR-B200SR-WH/TR-B200SR-IV units in the group to sound. This type of “local” grouping is accomplished by wiring the grouped

devices together using terminal 6, Sounder Base Interconnect, as shown in the diagram. Some Fire Alarm Control Panels (FACP) support the grouping of sounder

bases via software in lieu of the Sounder Base Interconnect.

NOTE: A local grouping of horns via the sounder base interconnect is not supervised, therefore the groups can only be used as a supplementary evacuation

system. It is not acceptable to group horns via the sounder base interconnect for primary alarm signaling. Sounder bases which are grouped via software are not

subject to this limitation and may be used as part of the primary alarm signaling.

DETECTOR ACTIVATES SOUNDER BASE(S);

INTELLIGENT RELAY MODULE ACTIVATES ALL SOUNDER BASES - (COMPLIES WITH UL 268 AND UL 464)

UL has approved grouping for up to six TR-B200SR-WH/TR-B200SR-IV sounder bases. When wired as a group, any detector in the group that has been activated

by the panel will cause other TR-B200SR-WH/TR-B200SR-IV units in the group to sound. This type of “local” grouping is accomplished by wiring the grouped

devices together using terminal 6, Sounder Base Interconnect, as shown in the diagram. Some Fire Alarm Control Panels support the grouping of sounder bases

via software in lieu of the Sounder Base Interconnect.

NOTE: A local grouping of horns via the sounder base interconnect is not supervised, therefore the groups can only be used as a supplementary evacuation

system. It is not acceptable to group horns via the sounder base interconnect for primary alarm signaling. Sounder bases which are grouped via software

are not subject to this limitation and may be used as part of the primary alarm signaling.

3 I56-3392TRG-011

4/22/2021

Triga™ is a trademark of TRIGA Life Safety Systems, LLC. System Sensor® is a registered trademark of Honeywell International, Inc.

4I56-3392TRG-011

©2021. 4/22/2021

This manual suits for next models

1

Other TRIGA Marine Equipment manuals

Popular Marine Equipment manuals by other brands

Garmin

Garmin FUSION APOLLO MS-WB675 manual

Harken

Harken MKIV Unit 3 installation manual

Power-Pole

Power-Pole Signature Series installation manual

Observator Instruments

Observator Instruments OMC-131 Installation and technical manual

Safran

Safran MorphoAccess SIGMA Series Administration guide

Selden

Selden Furlex 200 S manual