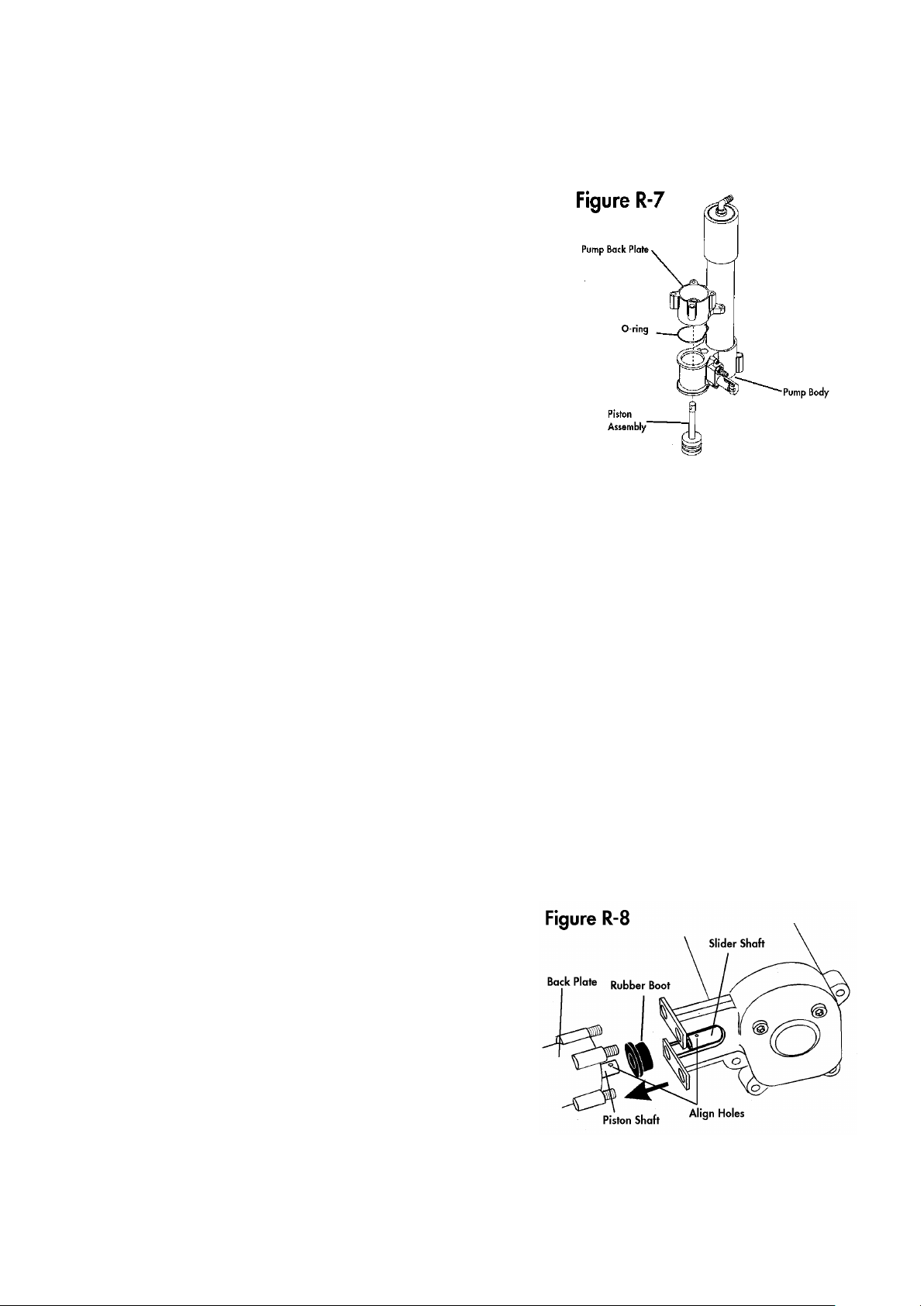

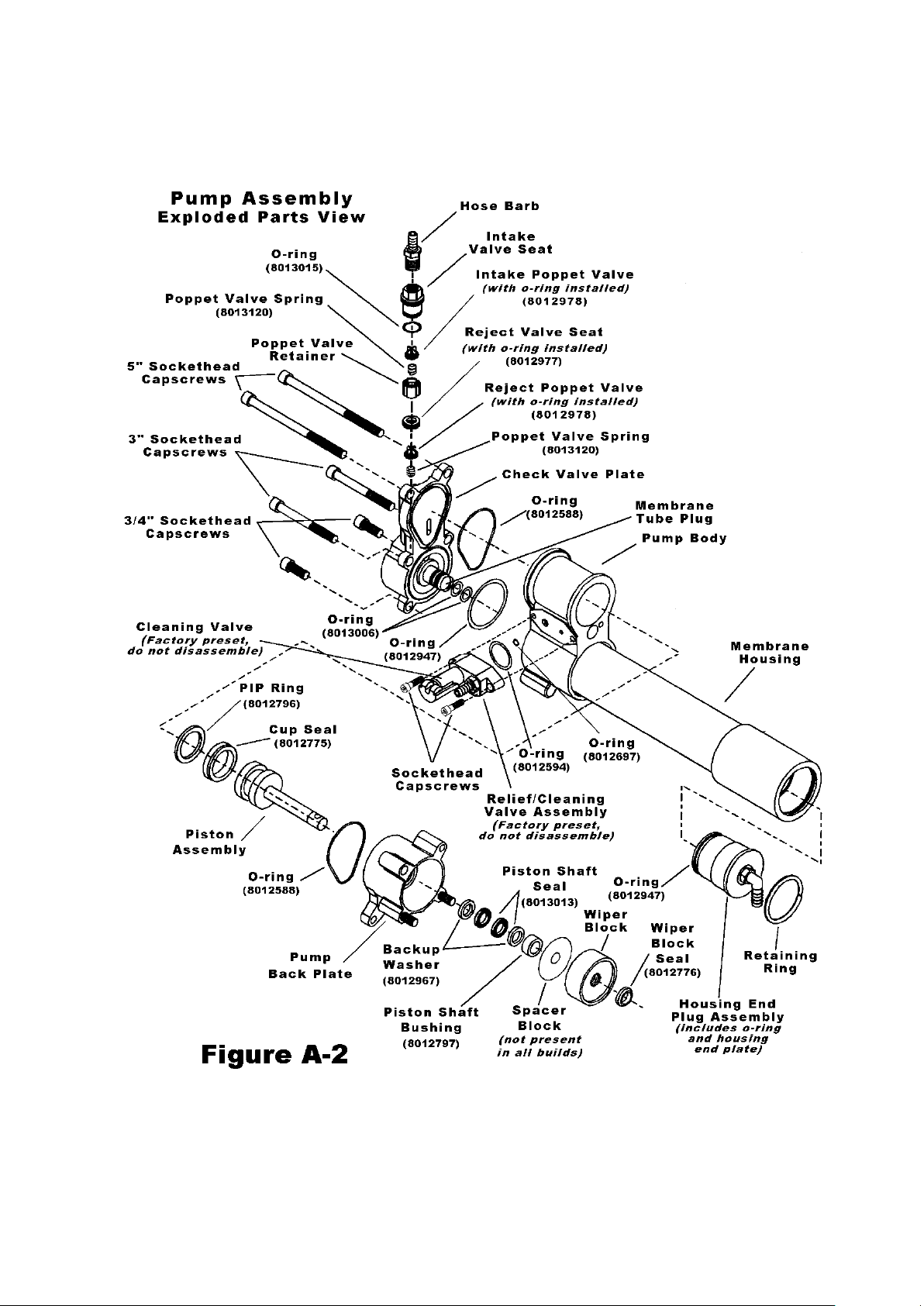

3. Lightly lubricate the cylinder in the pump body with silicon grease. Slide the finished piston assembly, shaft

first, into the pump body from the side of the pump body that faces the check valve plate. Install the large O-

ring (8012588) into its groove in the pump back plate and lower the pump back plate over the piston shaft.

The side of the back plate with the large O-ring should be facing the pump body. See Figure

R-7.

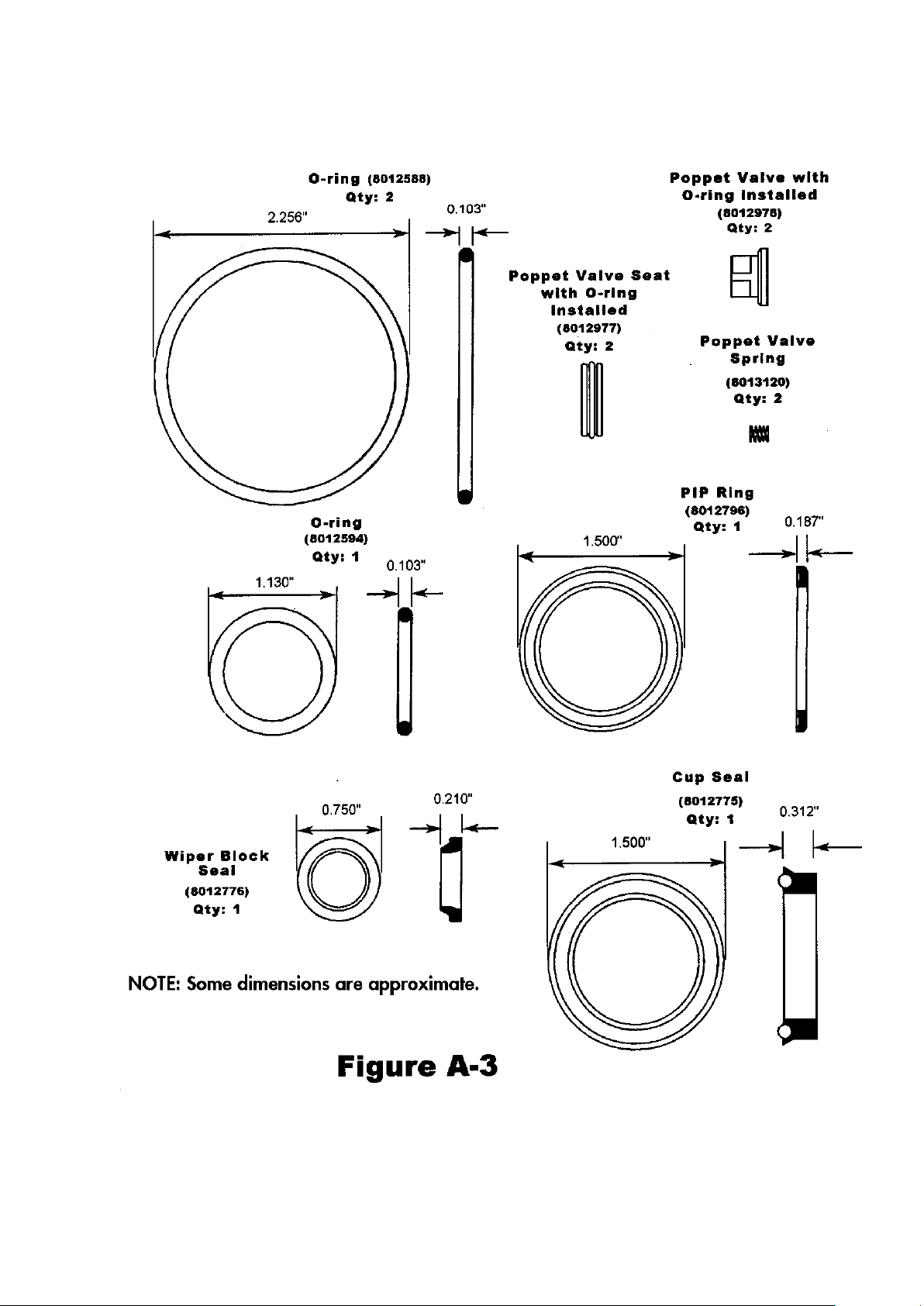

4. Refer to Figure R-4. Slide one of the white backup washers over the

piston shaft and press it into its bore in the pump back plate. Next,

slide one of the two black rubber piston shaft seals over the piston

shaft and work it into the bore on top of the backup washer. Note

that the shaft seals are flared out on one side. It is important that the

flared (wider) side should be down, facing the shaft bore. Install the

second piston shaft seal in the same way. It too should be installed

with its flared side facing down. Next, install the second white

backup washer and, finally, the white bushing. Slide the installation

tool (used in Step 2 above) over the piston shaft with the narrow

end facing the white bushing. Use the installation tool to press the

shaft washers, seals and bushing all the way into the bore. When

finished, the outside end of the bushing should be flush with the bore

opening.

5. Install a new wiper block seal (8012776) into the wiper block. The

seal must be pressed into a groove inside the bore in the middle of the wiper block with the narrower side

of the seal facing outwards. Form the seal into an oval shape by squeezing it between your fingers and press

one side of the seal into the groove in the wiper block. Once an edge of the seal is started into the groove,

carefully work the rest of the seal into place. After the seal has been installed, slide the spacer (if present)

and wiper block onto the piston shaft. The side of the wiper block from which the seal was installed should

be facing outward. Refer to Figure R-3.

6. Prepare the check valve plate for reassembly by installing the new poppet valves. Note that both the intake

and reject poppet valves and valve springs are identical. Refer to Figure R-5 during the following procedure:

A. Lower a new poppet valve spring (8013120) into the bottom of the bore in the check valve plate. Use

your little finger or the eraser end of a pencil to press it into its seat. It is designed to be a light press fit

and, when installed correctly, it should stay vertical in place during the next step.

B. Use needle-nosed pliers to carefully lower one of the new poppet valves (8012978) into the bore. The

poppet valve should rest on top of the spring with the poppet’s cross side facing up.

C. Lower the new reject valve seat (8012977) into the bore and use a finger to press it down as far as it

will go. Note that the hole in the middle of the valve seat has a beveled edge on one side. The side with

the beveled edge must face downward; i.e., it must face the poppet valve. When properly installed, the

valve seat should fit neatly over the poppet valve. Test the poppet valve by pressing it with the eraser

end of a pencil. It should move up and down slightly and seat squarely in the valve seat.

D. Locate the small depression in the center of one end of the poppet valve retainer and press the second

valve spring (8013120) into the depression. It was

designed as a light press fit and should stay in place after

being installed. Then lower the poppet valve retainer into

the bore in the check valve plate with the spring facing

upward.

E. Lower the second poppet valve into the bore in the check

valve plate and rest it carefully on top of the valve spring.

F. Remove the old o-ring (8013015) from the intake valve seat

and replace it with the new one from the RSK. Carefully

screw the intake valve seat into the check valve plate and

tighten with a 5/8" open end wrench. Use the eraser end

of a pencil or a small allen wrench to test the operation of

the intake poppet valve. The poppet valve should move down slightly and then spring back up against

its seat. Re-install the hose barb if intact, or replace it with a hose barb, delivered with the kit.