Overview

Frequently-asked Questions

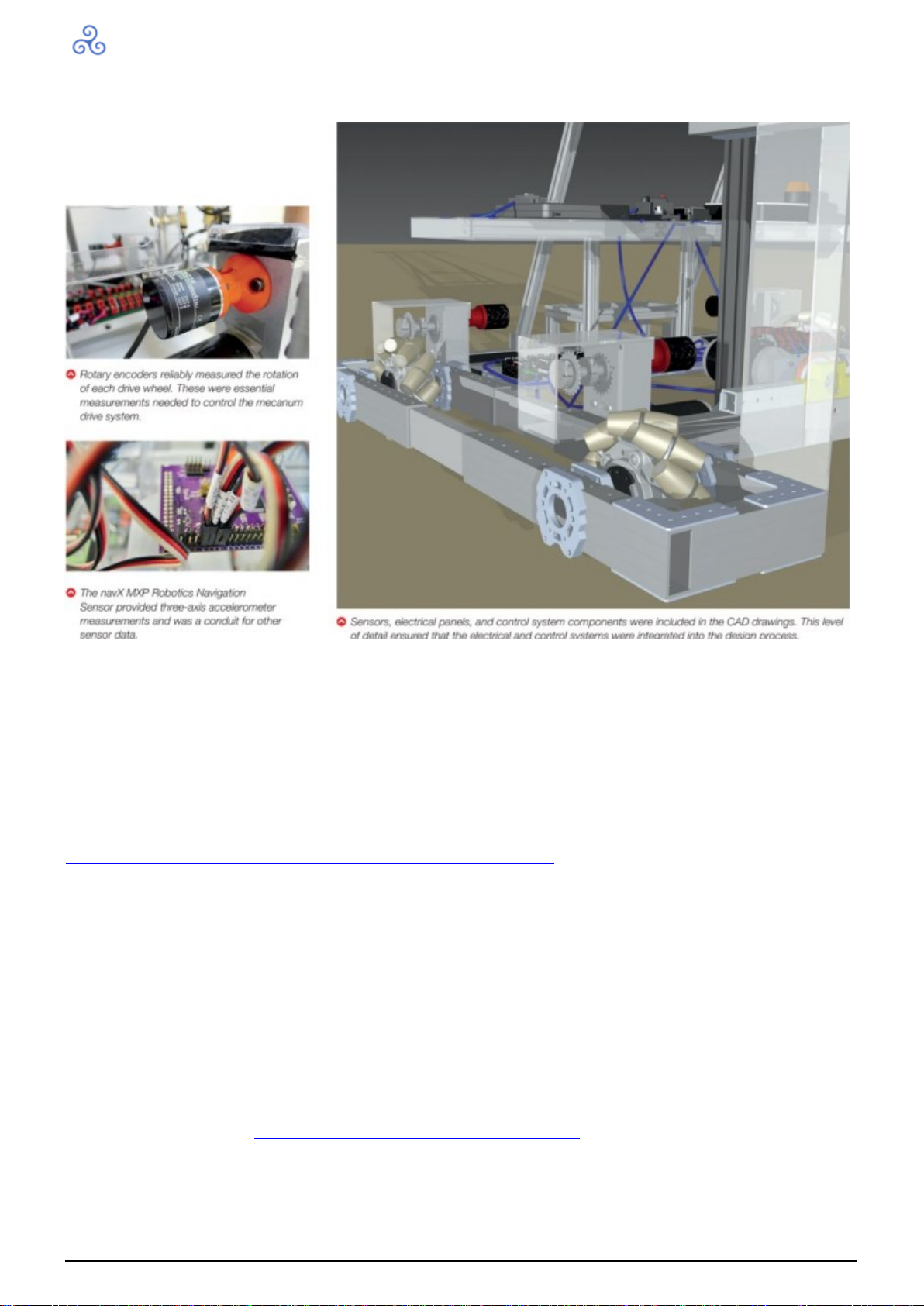

readings. Once the magnetometer is calibrated, navX-MXP will return either an accurate

magnetometer reading, or an indication that its measurement of the earth’s magnetic

field has been disturbed.

Magnetometer readings taken at the beginning of a match, when combined with the

navX-MXP yaw measurements, enable a robot’s pose and absolute heading to be

maintained throughout the match. This feature of the navX-MXP is referred to as a

“9-axis” heading.

Why do the Yaw angles provided by the navX-MXP drift over time?

The short answer is that the yaw angle is calculated by integrating reading from a

gyroscope which measures changes in rotation, rather than absolute angles. Over time,

small errors in the rotation measurements build up over time. The navX-MXP features

sophisticated digital motion processing and calibration algorithms that limit this error in

the yaw angle of ~1 degree per minute. For further details, please see the Yaw Drift

page.

Can the navX-MXP “Displacement” estimates be used for tracking a FRC or FTC robot’s

change in position (dead-reckoning) during autonomous?

Accelerometer data from the navX-MXP’s onboard MPU-9250 are double-integrated by

the navX-MXP firmware to estimate displacement, and are accurate to approximately 1

meter of error during a 15 second period.

To track a FRC or FTC robot’s position during autonomous requires an accuracy of

about 1 cm of error per 15 seconds. While the accuracy of the navX-MXP displacement

estimates might be good enough to track the position of an automobile on a road, it is

too low for use in tracking a FRC or FTC robot’s position during the 15 second

autonomous period.

The root cause of the displacement estimate error rate is accelerometer noise.

Estimating displacement requires first that each acceleration sample be multiple by itself

twice (cubed), and then integrated over time. Practically, if a noisy signal is cubed, the

result is very noisy, and when this very noisy value is integrated over time, the total

amount of error grows very quickly.

The current noise levels (approximately 150 micro-g per square-root-hertz) would need

to be reduced by a factor of 100 (two orders of magnitude) before displacement

estimates with 1 cm of error per 15 seconds can be achieved by double-integration of

7