GB

TABLE OF CONTENTS

A 1 User information ..........................................................................................................................................2

A 1.1 Meaning of the pictograms ..................................................................................................................2

A 1.2 Important information ..........................................................................................................................2

A 1.3 Precautions ..........................................................................................................................................2

A 2 Scope of delivery –Accessories ................................................................................................................3

A 3 Mains voltage – Mainsfrequency ..............................................................................................................4

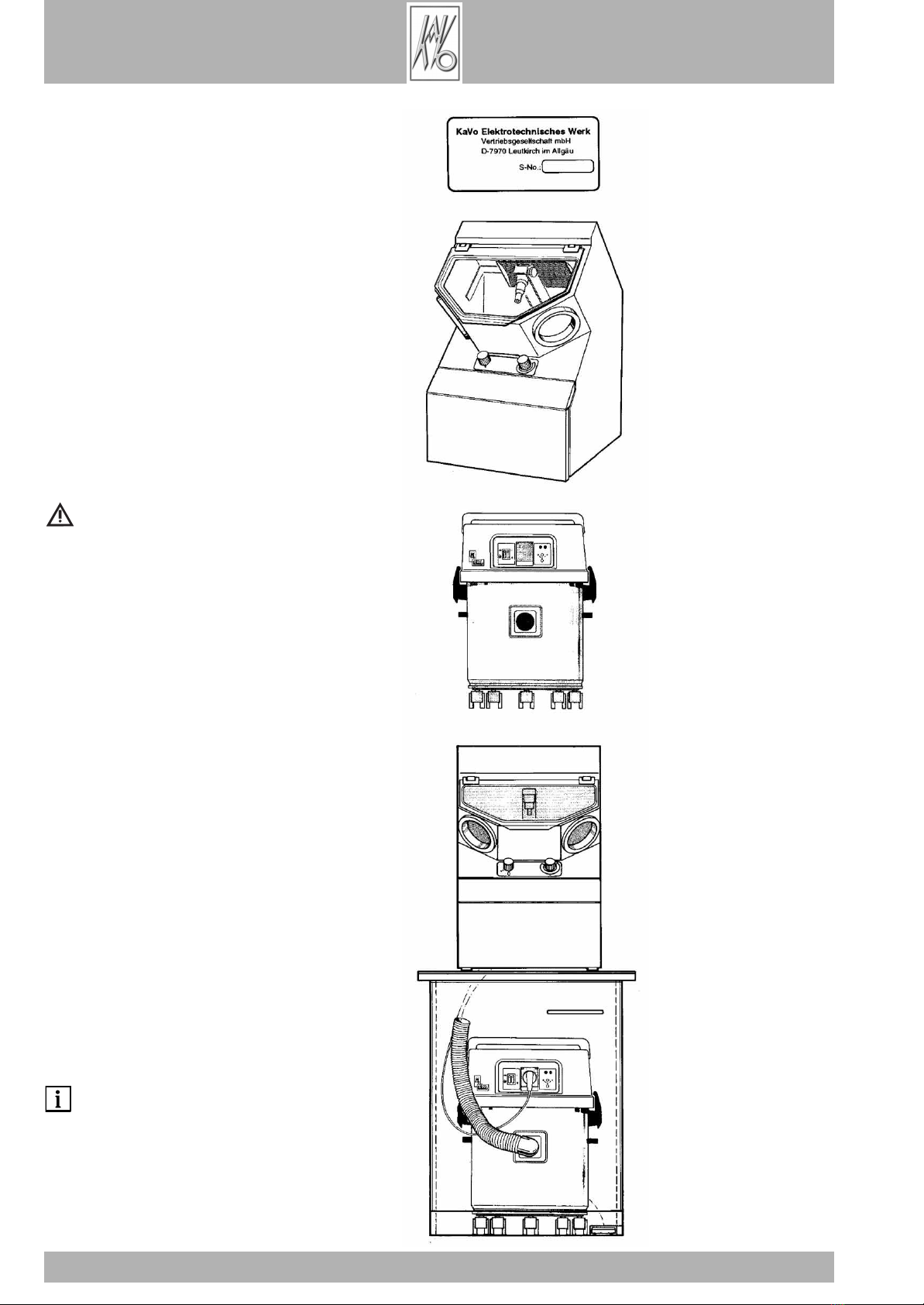

A 4 Location ........................................................................................................................................................4

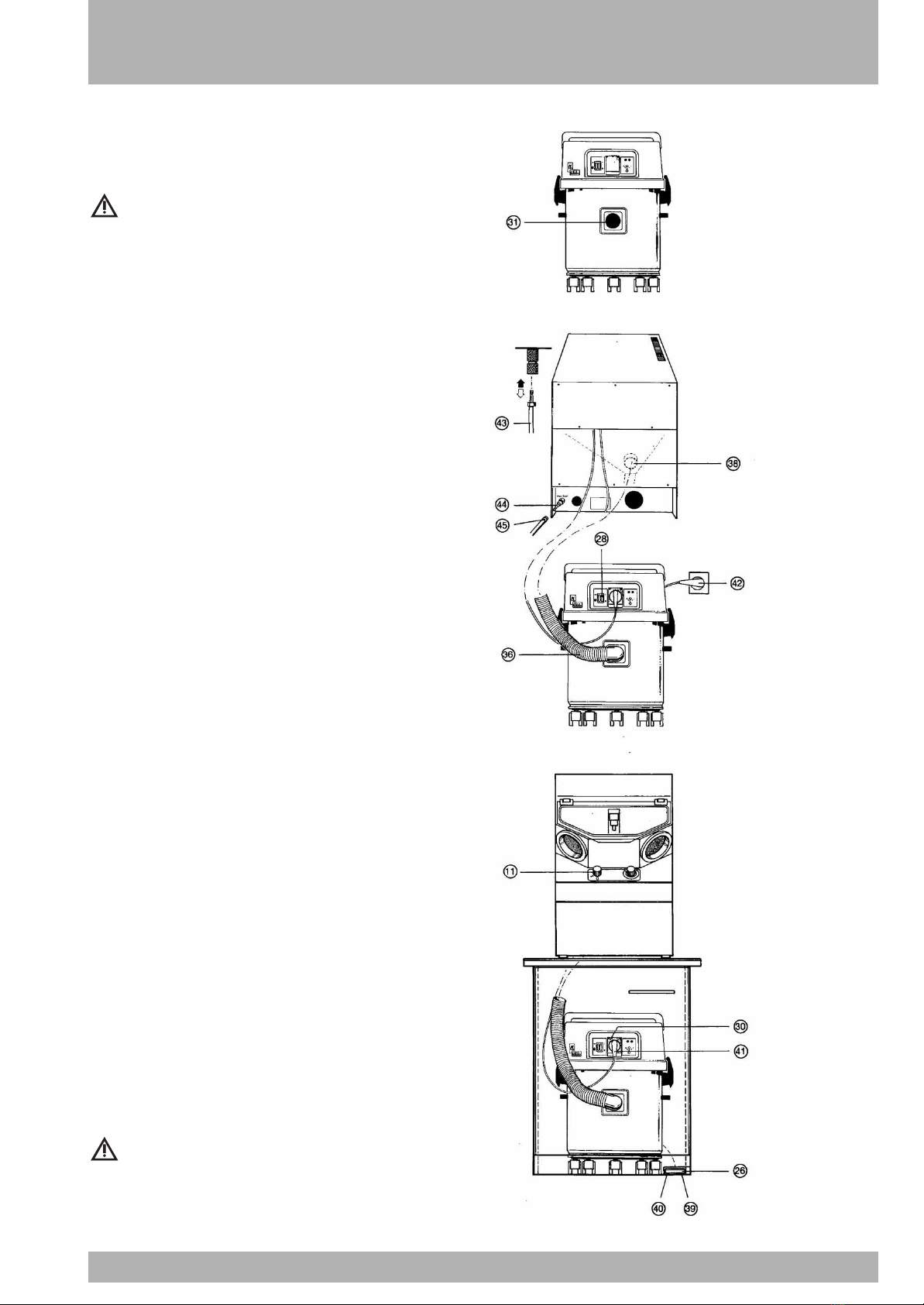

A 5 Mounting and connection ..........................................................................................................................5

A 6 Preperations for commencing operation ..................................................................................................6

A 6.1 Filling the abrasive container DP in the recirculating blasting range ..................................................6

A 6.2 Filling the abrasive containers inthe disposable abrasive range. ........................................................6

A 6.3 Fitting gloves or cuffs EM ....................................................................................................................7

A 6.4 Setting the blasting pressure in the recirculating blasting range. ........................................................7

A 6.5 Setting the blasting pressure in the disposable abrasive range. ........................................................7

A 6.6 Dust collector EWL 5030 ......................................................................................................................8

A 7 Organes de commande et defonctionnement ..........................................................................................9

A 8 Operation ....................................................................................................................................................11

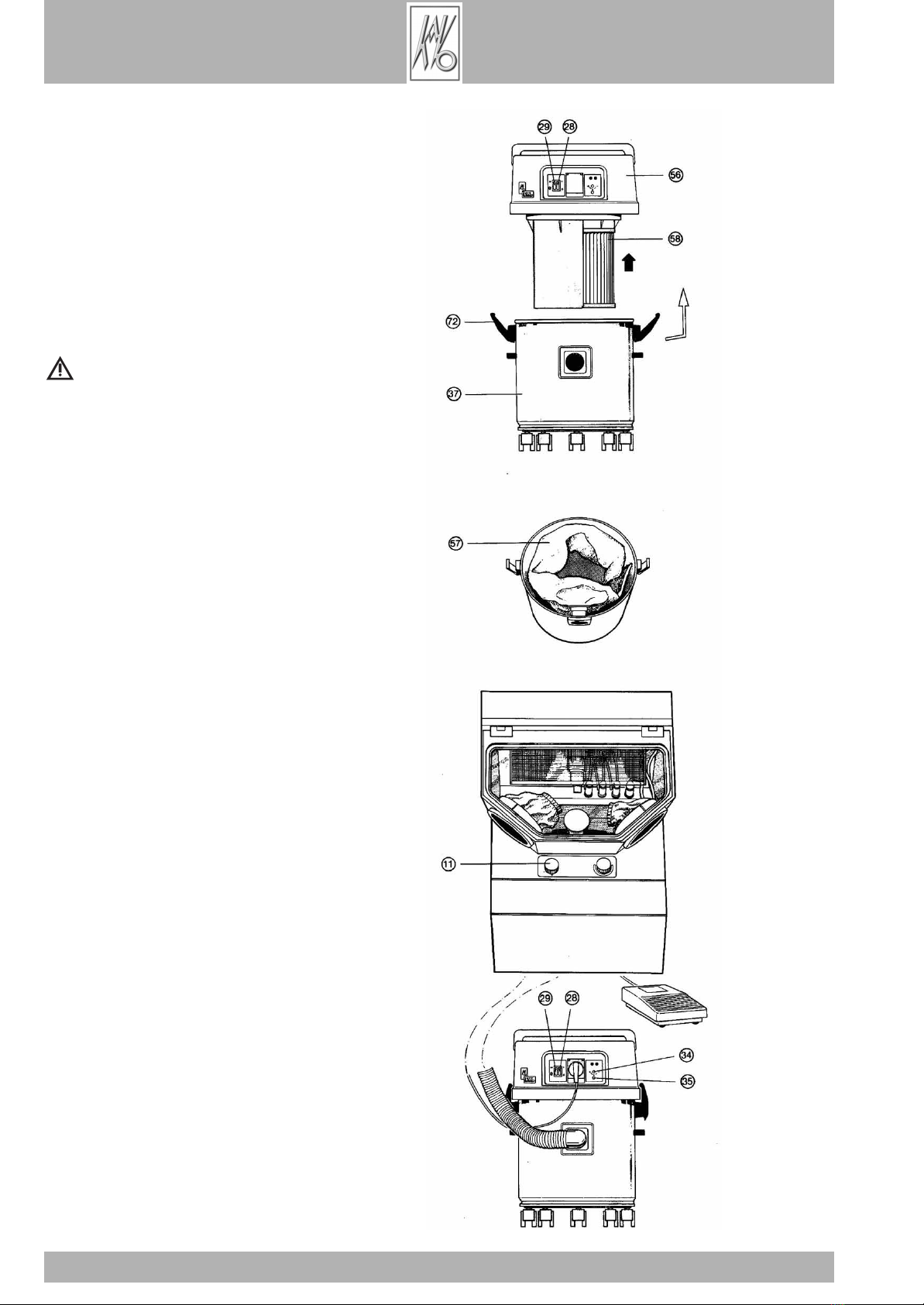

A 8.1 Dust collector EWL 5030 ....................................................................................................................11

A 8.2 All purpose blasting station EWL 5423 ..............................................................................................12

A 8.3 Abrasive blasting in the recirculating blasting range ..........................................................................13

A 8.4 Fine blasting in the disposableabrasive range ..................................................................................14

A 9 Maintenance ..............................................................................................................................................15

A 9.1 Apply a touch of oil or grease to the chisel EWL 5419 once a month. ..............................................15

A 9.2 Changing gloves/cuffs ........................................................................................................................15

A 9.3 Changing the abrasive in the recirculating blasting range ................................................................16

A 9.4 Refilling the storage containers in the disposable abrasive range ....................................................16

A 9.5 Changing nozzles in the disposable abrasive range. ........................................................................16

A 9.7 Changing the protection shield ..........................................................................................................17

A 9.8 Changing the fluorescent tube ..........................................................................................................17

A 9.9 Dust collector EWL 5030 ....................................................................................................................18

A 9.10 Changing the micro filter ..................................................................................................................18

A 10 Operating faults ........................................................................................................................................19

A 11 Technical data ............................................................................................................................................22

Guarantee conditions ..................................................................................................................................24

Declaration of conformity ..............................................................................................................................25

Spare parts EWL 5328..................................................................................................................................26

Spare parts EWL 5419..................................................................................................................................32

Spare parts EWL 5030..................................................................................................................................33

K-Control-control unit 1