Kawneer reserves the right to change conguration without prior notice when deemed

necessary for product improvement.

© Kawneer Company, Inc., 2013

Laws and building and safety codes governing the design and use of glazed

entrance, window, and curtain wall products vary widely. Kawneer does not control

the selection of product congurations, operating hardware, or glazing materials,

and assumes no responsibility therefor.

2

kawneer.com

EC 97904-076

Kawneer 1786 Rim Exit Device

INSTALLATION INSTRUCTIONS

APRIL, 2018

038311EN

OPTIONAL TRIM

1786 RIM EXIT DEVICE LEVER HANDLE TRIM ASSEMBLY/INSTALLATION INSTRUCTIONS:

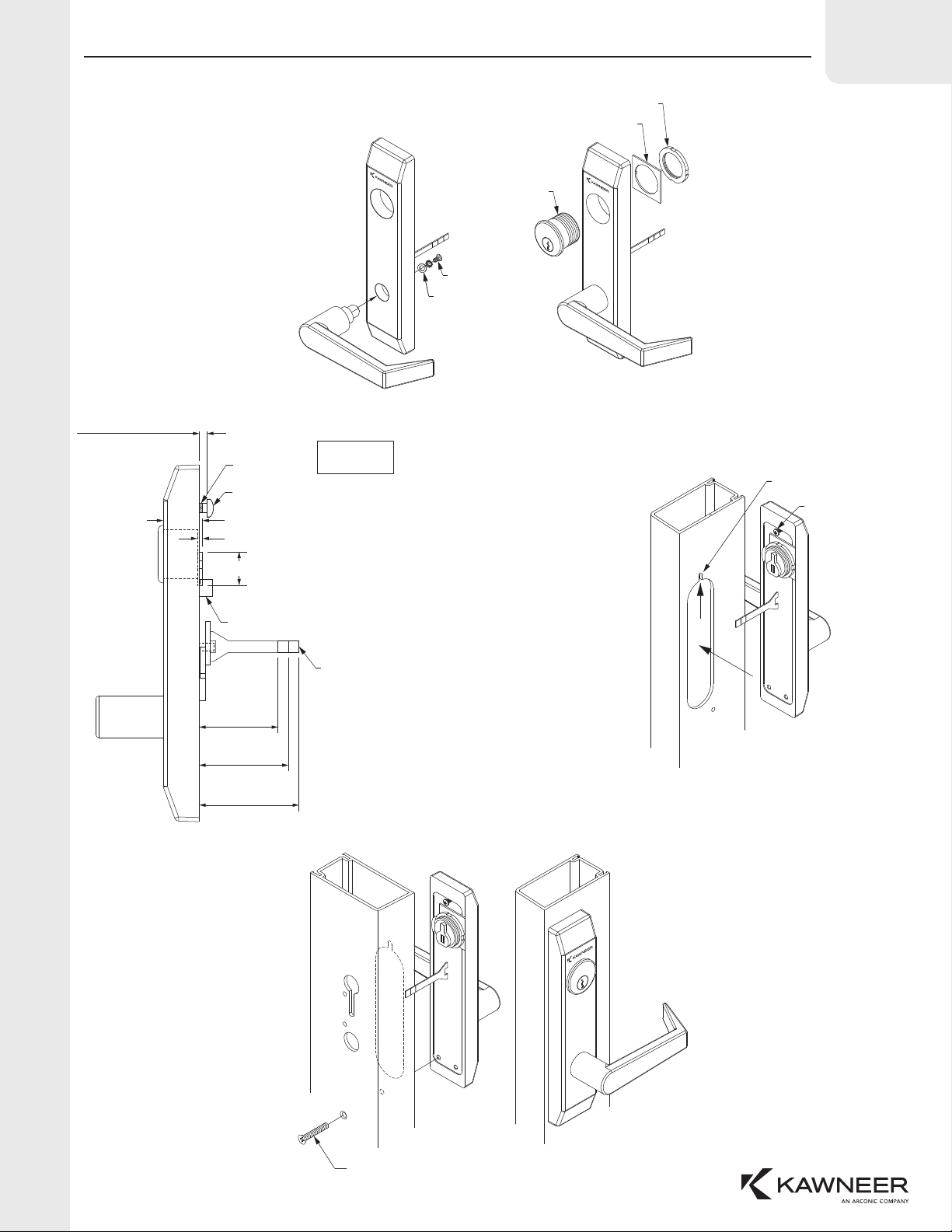

1) Trim mounting base is handed to accommodate a left or right handle application. To construct a left hand (LH) lever handle, rotate cam clockwise

making sure the cam pin aligns with slot on left side of cam guide. (See Illustration below) Once the pin is in position, slightly push up and hold

cam guide and cam while inserting lever handle rmly into place within the trim mounting base. The tail piece will now be oriented in the vertical

position.

2) To construct a right hand (RH) lever handle, rotate cam counter clockwise making sure the cam pin aligns with slot on right side of cam guide. (See

Illustration below) Once the pin is in position, slightly push up and hold cam guide and cam while inserting lever handle rmly into place within the

trim mounting base. The tail piece will now be oriented in the vertical position.

3) Assemble (1) 1/4" -20 x 1/2" Phillips pan head fastener with (1) steel at washer and (1) lock washer to secure lever handle to trim mounting base.

4) Insert 15/16" key cylinder (dummy cylinder on inactive door leaf) into top hole of trim mounting base. Align mounting guide plate to key cylinder and

secure with retaining ring.

5) When using a key cylinder longer than 15/16", cylinder rings will be required to maintain a 1/8" cylinder projection. When using a dummy cylinder

on inactive door leafs, place the lock arm switch in a lock position to disable the lever handle function.

6) Before installation of trim mounting base, cut break-away tail piece to the correct length. (see illustration)ation.

7) Find (1) 1/4"-20 x 3/4" Phillips pan head fastener and apply several drops of thread locker liquid to lower threads. Install Phillips pan head fastener

into trim mounting base and set to accommodate a 1/8" (Standard/Thermal door) or 3/16" (Heavy Wall) wall thickness. (Fastener may require

additional adjustment to ensure that trim mounting base is fully secured into position.)

8) On exterior side of door stile, position lever handle trim assemble into cutout, just below the fastener slot cutout. Being careful not to scratch the

exposed nish surface, slide lever handle trim assemble up to engage fastener into slot.

9) On interior side of door stile, install (1) fastener (see below) through door to secure lever handle trim assembly in position.

(1) #10-24 x 2 1/4" FHMS for Standard 1-3/4" doors

(1) #10-24 x 2-1/2" FHMS for Heavy Wall 2" doors

(1) #10-24 x 2-3/4" FHMS for Thermal 2-1/4" doors

10) Lever handle trim assemble should be tightly secured to ensure that hardware is placed square upon door stile and cannot be moved.

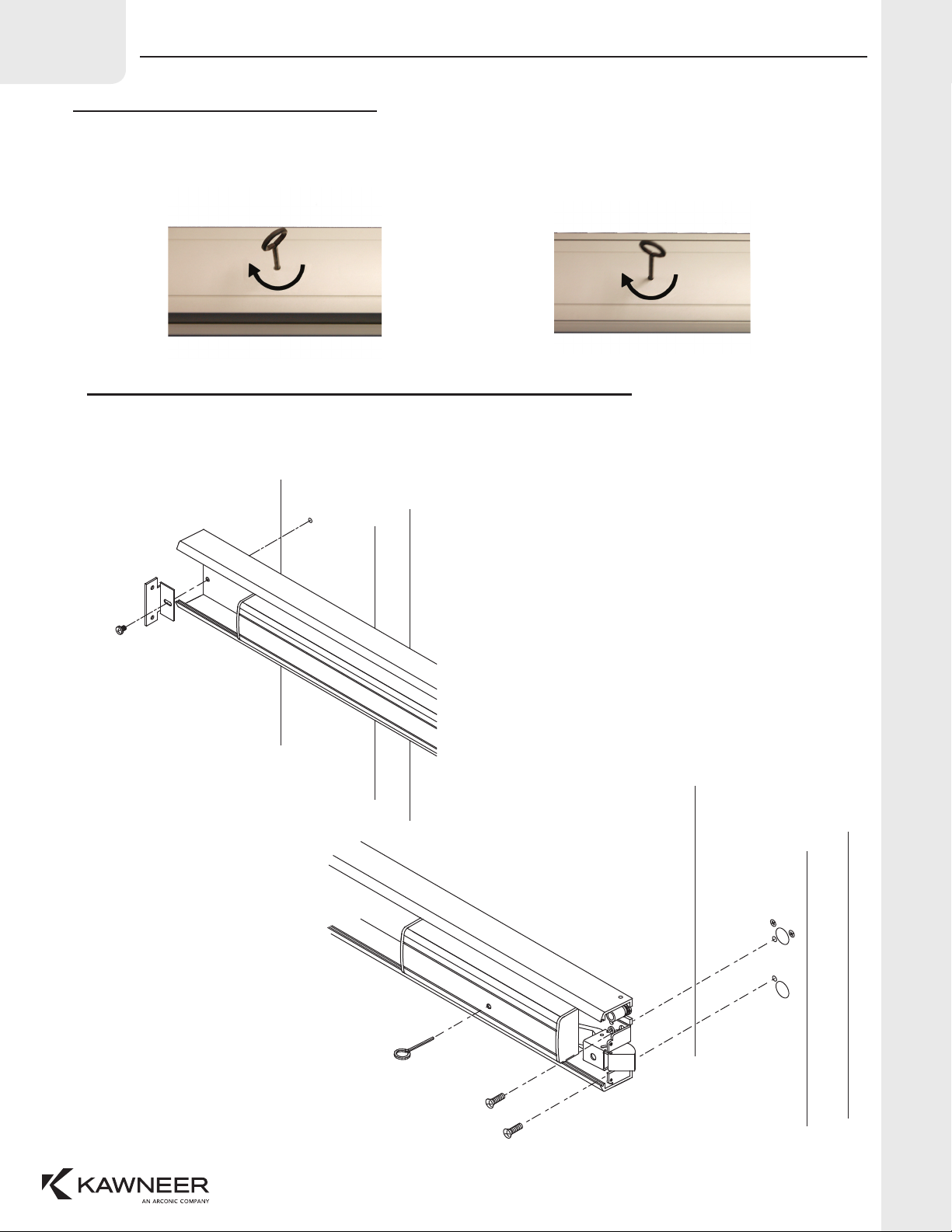

11) Upon completion, insert cylinder key and turn clockwise to unlock, then counter- clockwise to lock.

12) Install rim exit device.

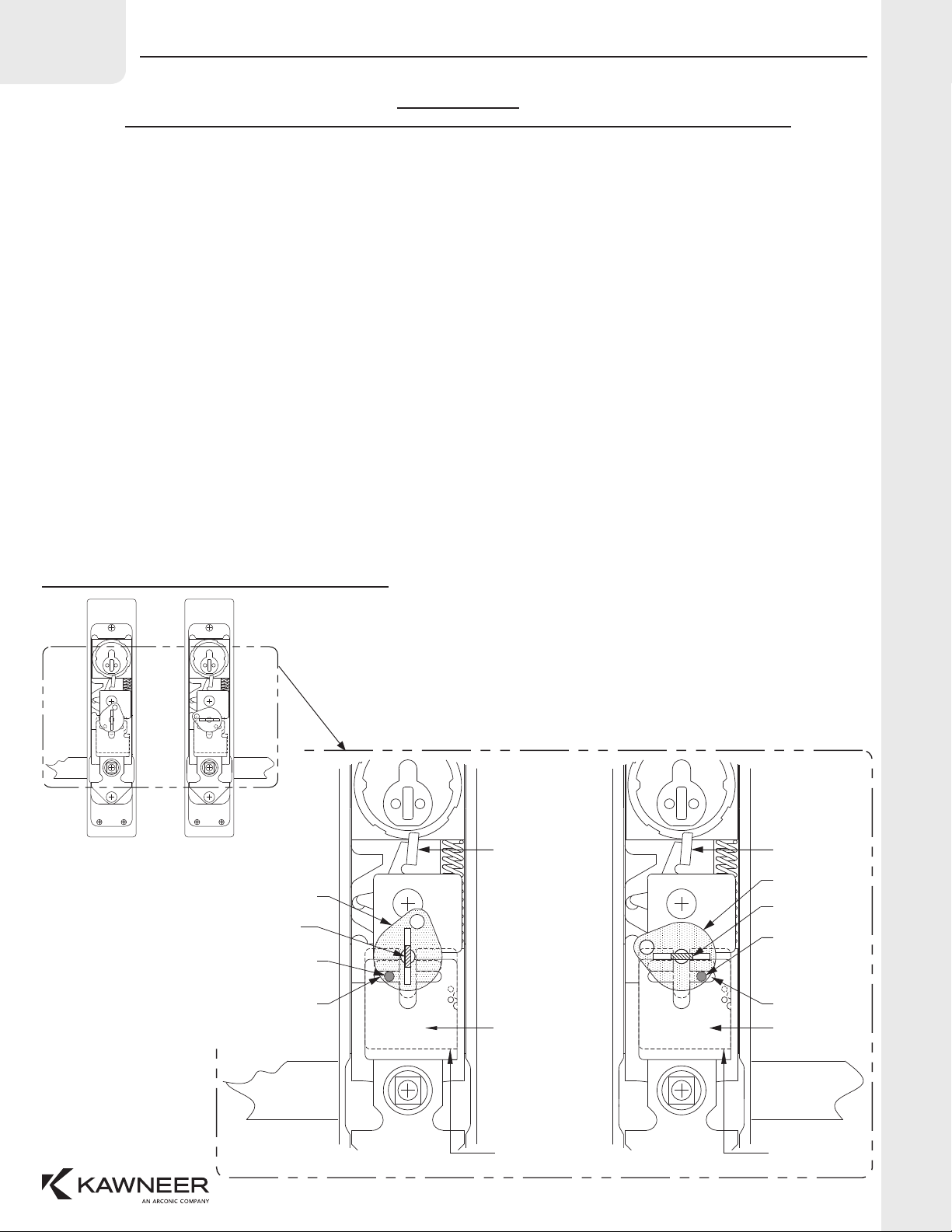

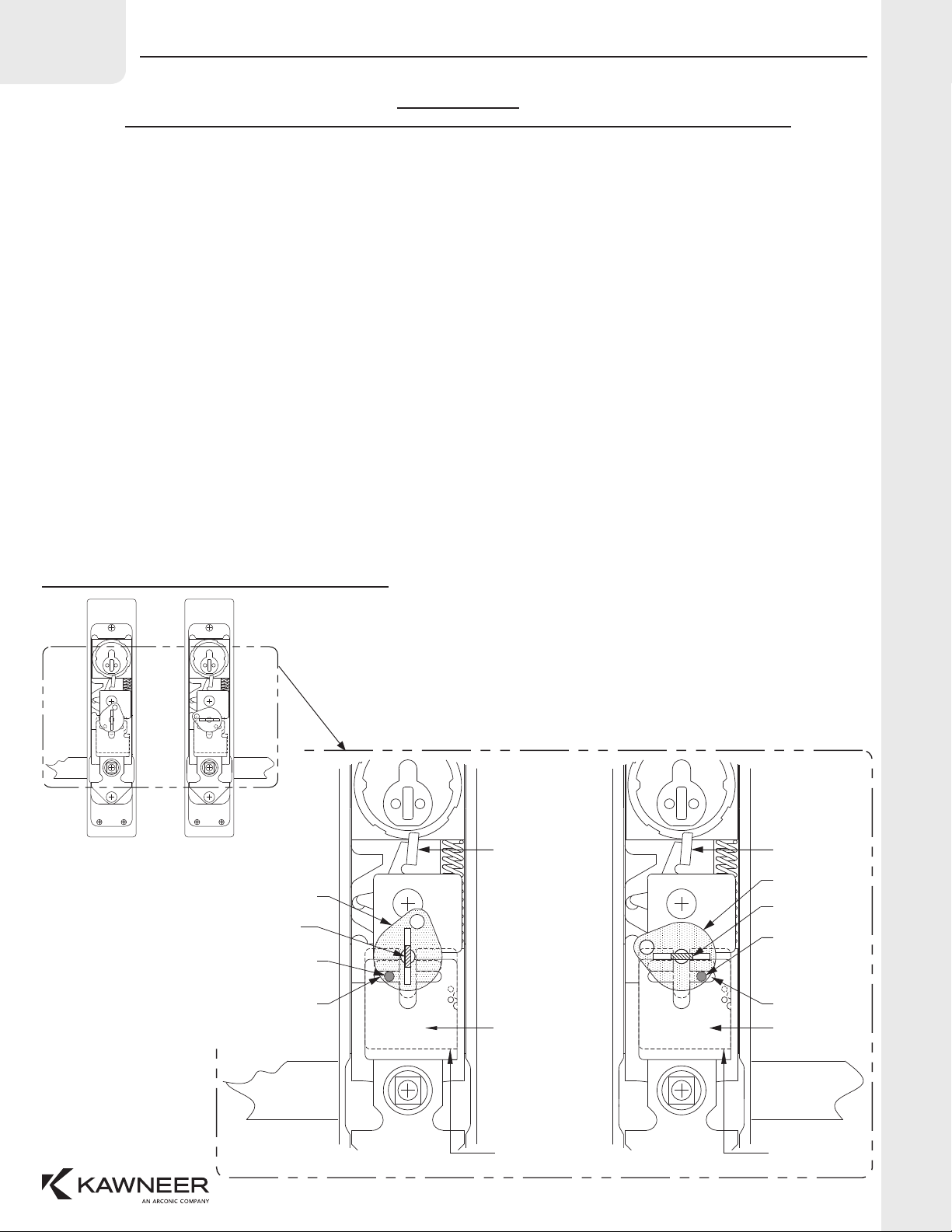

1786 RIM EXIT DEVICE TRIM HANDING GUIDE:

Cam Lift Pin

Cam

Cam

Guide

Lever

(LH)

Lever Handle

(Shown LH Single

Active Pair)

Lever Handle

(Shown RH Single

Inactive Pair) Cam

Cam Lift Pin

Cam

Guide

Tail Piece

(Vertically)

Left Slot

Lever

(RH)

Lock Arm Switch Lock Arm Switch

Right Slot

Tail Piece

(Horizontally)

Push Up and

Hold Cam Guide

Push Up and

Hold Cam Guide