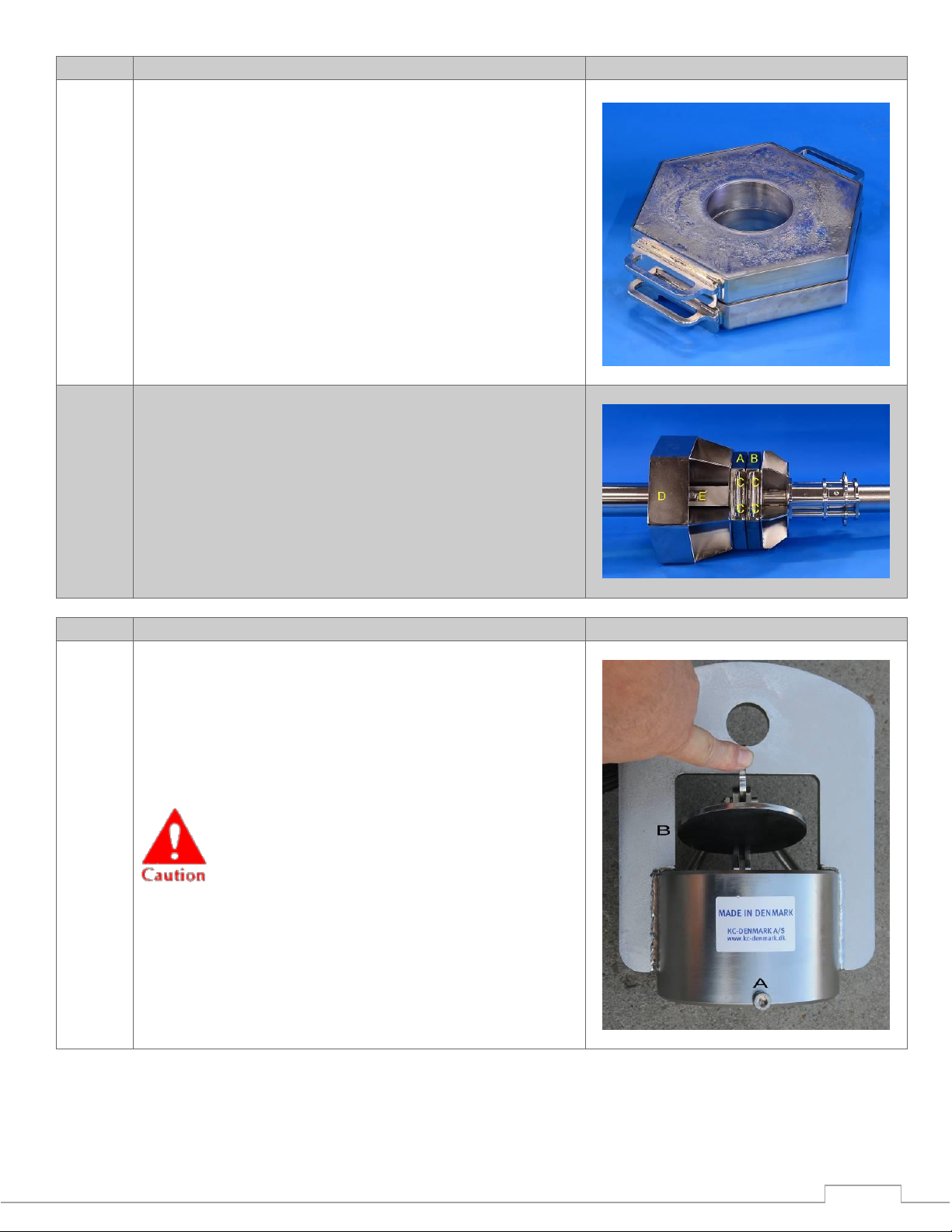

Requires an extension kit 13.795, shown to the right.

The principle for operating the piston corer function:

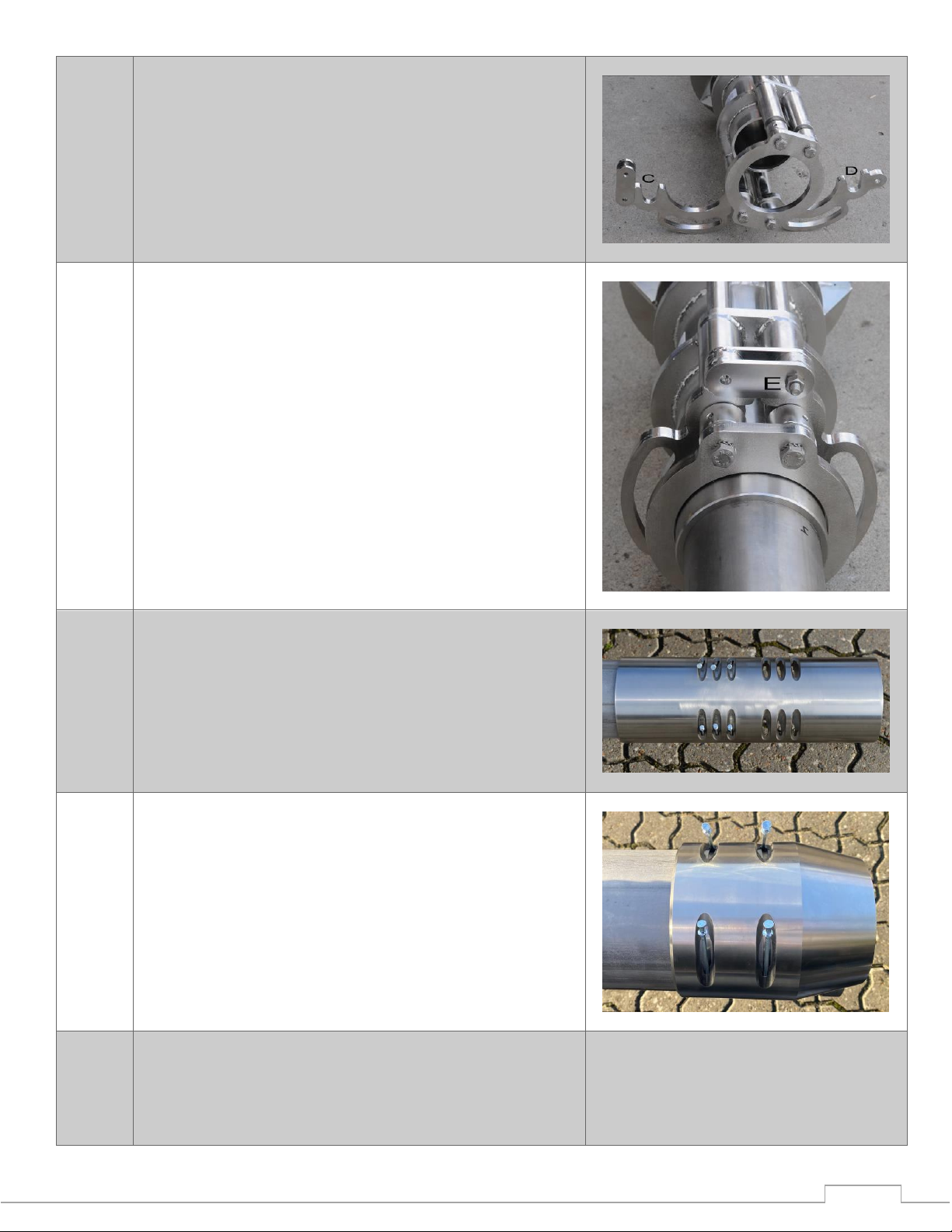

An AISI 316 stainless steel heavy-duty releaser (pos.

1), based on the Kullenberg principle, is mounted at

the top. Up to 20 lead weights (pos. 4) of 80 kg, each

can be added. The upper part of the corer is made of

AISI 316 stainless steel.

The corer tube (pos. 9) is made of AISI 316 stainless

steel (Ø140/Ø130 mm). At the end of the releaser

hook (pos. 1); the 30 kg release weight (pos. 7) is

mounted.

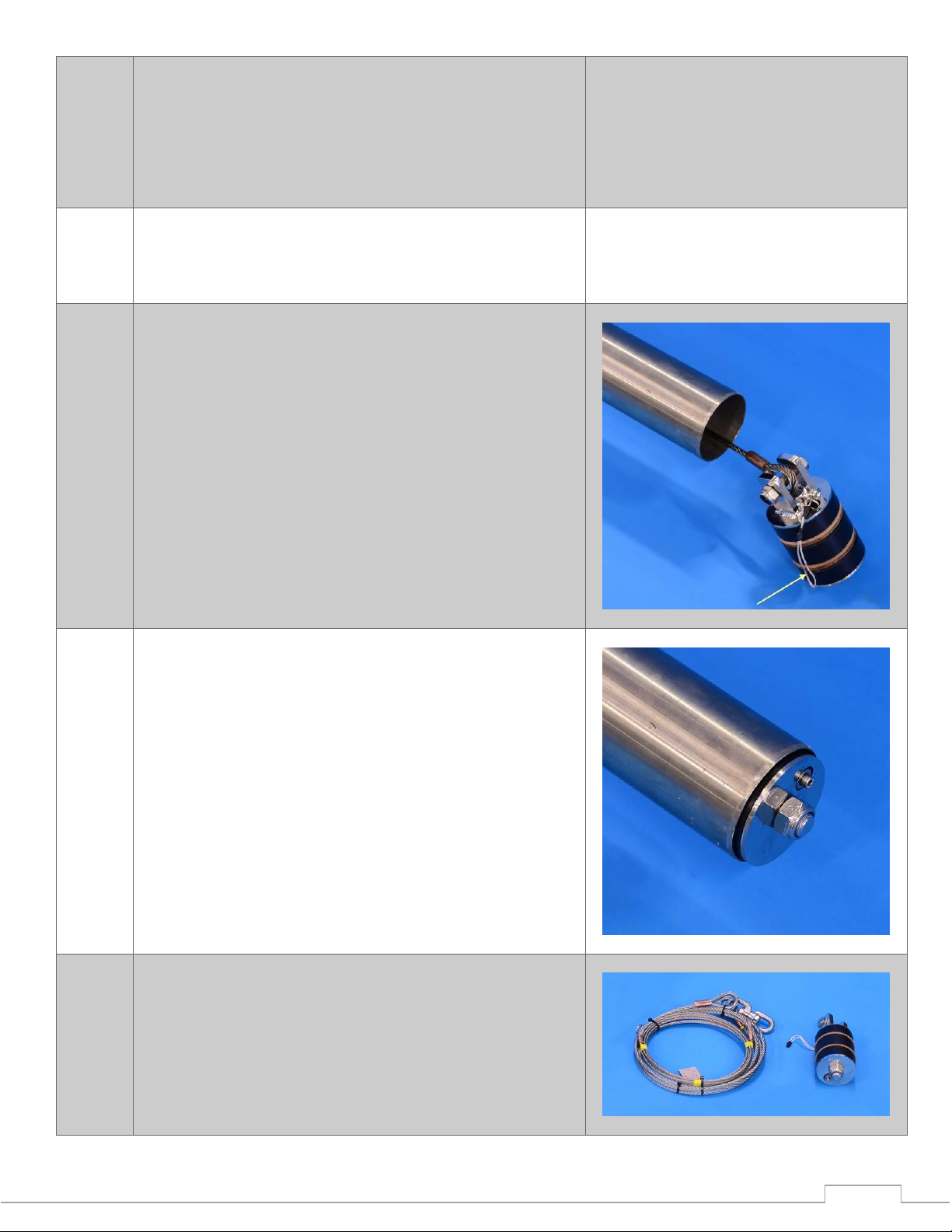

A piston with a leather seal, (pos. 8) is positioned at

the bottom of the corer tube. The piston is connected

to the releaser (pos. 1) by an Ø8 mm stainless steel

AISI 316 steel wire. During the deployment the corer

tube (pos. 9) is released 1,7 meter above the sediment

as the releaser weight reaches the sediment surface.

The wire (pos. 8), which has a slack of about 1 meter,

allows the corer tube to fall free until the piston (pos.

7) is activated just before the corer tube enters the

sediment. The total weight load can regulate the depth

of penetration. (pos. 4).

The principle for operating the piston corer function:

1. Kullenberg releaser

2. Wire (Ø8 mm) for piston

3. Steering fins

4. Lead weight

5. Lock for corer tube

6. Wire (Ø5 mm) for Kullenberg releaser and 30 kg

weight station

7. Weight station, 30 kg

8. Piston

9. Corer tube

14. Safety split

NOTE:

When using other lengths of sample tubes, the length

of the two steel wires must be changed accordingly.