Parts List

The following parts are included in the

KE2 Evaporator Eciency (KE2 Evap) controller kits:

Kit #20178 with 120/208-240 VAC controller

Kit #20844with 120/208-240 VAC controller

Kit #20631with 120/208-240 VAC controller

Kit #21096with 120/208-240 VAC controller

Kit #20222Beacon® I & II replacement controller

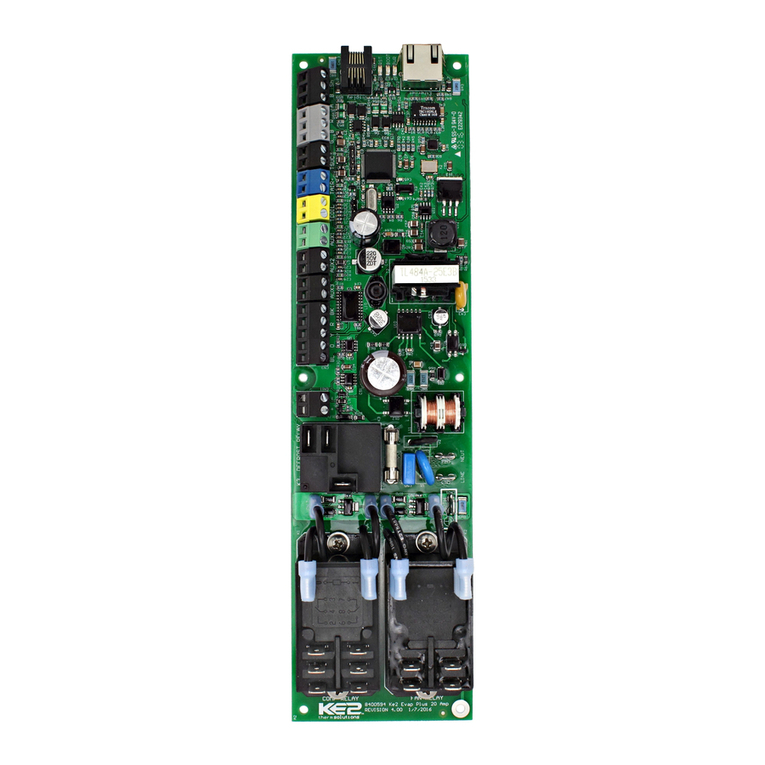

(1) KE2 Evaporator Eciency controller

(1) high voltage safety shield

(3) 10’ temperature sensors

(4) 90 degree quick disconnects

(5) self-tapping screws

(2) course thread screws (1) ne thread machine screw with

lock washer

(1) KE2 Terminal Board

(1) KE2 Evap Navigation sticker

(2) 1/2” plastic knockout plugs

(4) wire ties (rated for low temp)

(1) Air sensor mount

(1) 5-position screw down terminal (for EEV)

(4) 3-position screw down terminals (for power in, transducer

and 3A relay)

(9) 2-position screw down terminals (for sensors and digital

input, analog output)

1) 120 Voltage jumper

(1) 208-240V Voltage jumper (already on back of KE2 Evap)

© Copyright 2015 KE2 Therm Solutions, Inc., Washington, Missouri 63090

Q.1.3

July 2015

KE2 EvaporatorEfciency

Quick Start Guide

Supplies List

The KE2 Evap is supplied with all of the accessories required for the con-

troller to work, however, standard truck stock items will also be required

to install the controller. To simplify the installation, a list of items has

been provided.

Conduit to go between the controller and the evaporator

(2) Conduit connectors (straight or elbow as required)

(11) High voltage wires matched to the load of the heaters, fans,

liquid line solenoid, alarm (if used), and the controller.

(8) Spade Connectors matched to gauge of high voltage wires

Wire labeling (numbers, colors, etc.)

Additional wire ties

18 gauge twisted shielded pair (if extending sensor wires)

Foam insulation if running wires outside the space.

Silicone (for sealing any box penetrations)

Accessories to Aid in Installation

The following parts are available separately:

10’Wire Harness pn 20736,

25’Wire Harness pn 20670

40’Wire Harness pn 20737

KE2 Evap Mounting Box pn 20687

Further information on the Wire Harness and Mounting Box can be found in

literature Q-1-21.

L M N

DE

OP

F

B

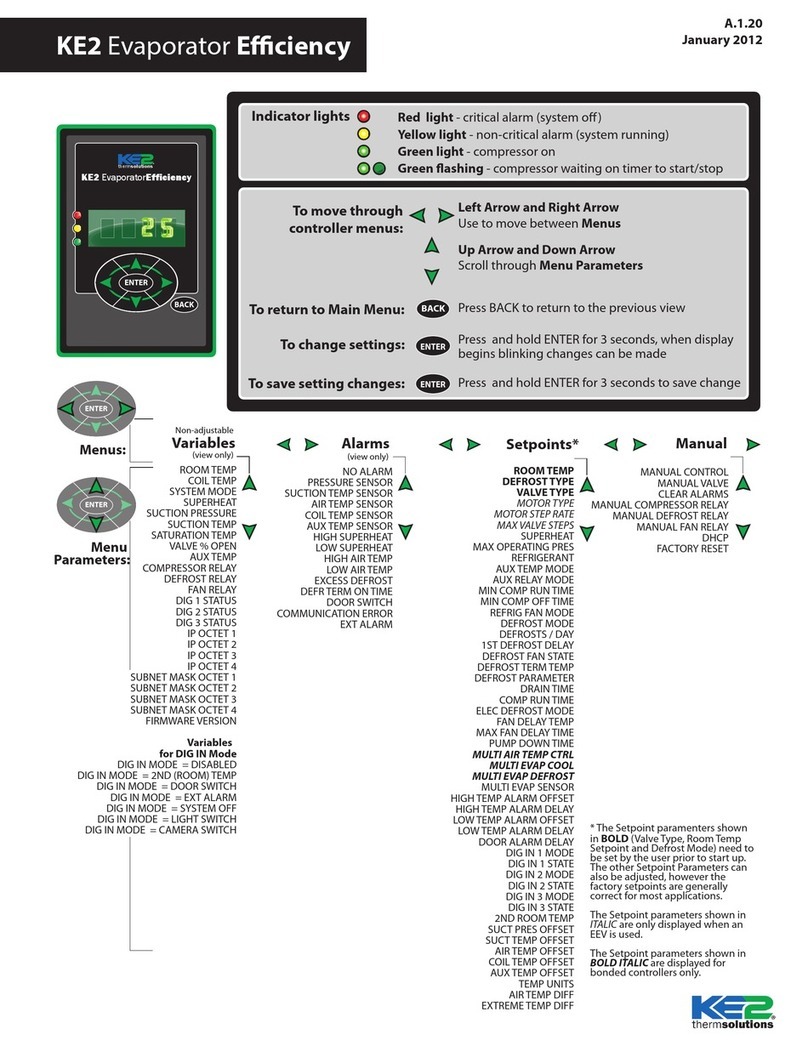

Left Arrow & Right Arrow

Use to move between Menus columns

Up Arrow & Down Arrow

Scroll through Menu Parameters

ENTER

Press and hold ENTER for 3 seconds, when

display is blinking changes can be made.

BACK

Press BACK to return to the previous view.

Press and hold ENTER for 3 seconds.

Change settings:

Save changes:

Moving through controller menus:

Return to Main Menu:

Lights: Red - critical alarm (system not running)

Yellow- non-critical alarm (system running)

Green - compressor should be on

- compressor waiting on timer to start/stop

ENTER

Press ENTER to go from parameter to value.

Togglebeween

description & value :

Menu Layout:

Variables Manual*

(view only)

Alarms

(view only)

ENTER

Setpoints Enter

Password

NO ALARM

EMAIL FAILURE

ROOMTEMP

DERIVATIVE

ROOMTEMP

FIRMWAREVERSION

MANUALCONTROL

CLEAR MD

Controller Navigation

ENTER

ENTER

BACK

Press BACK 3 - 4 times

If you lose your place:

*For manual defrost use MANUAL CONTROL

BACK

24-hour Emergency Support: 1.888.337.3358 www.ke2therm.com

pn 21061 9-14

AC

G H

IJ

K

This reference should remain on site with the installed KE2 Evaporator Eciency controller.

A

C

D

E

F

G

H

I

J

K

L

M

N

B

O

P

20844 KE2 Ultimate Install kit includes KE2 Mounting Box pn 20687 and 40’

colored temperature sensors

20631 kit does not include temperature sensors

21096 KE2 Supermarket Retrot kit also includes KE2 Mounting Box pn 20687,

10’ Wire Harness pn 20736, Ethernet Adaptor pn 20938, & Door Switch 20543

20222 Beacon® kit includes an extra temperature sensor, and pressure

transducer with cable.

Now with

Smart Access!

Get your controller

online in 3 easy steps.

See page16