Q.1.35 October 2015

Page 2

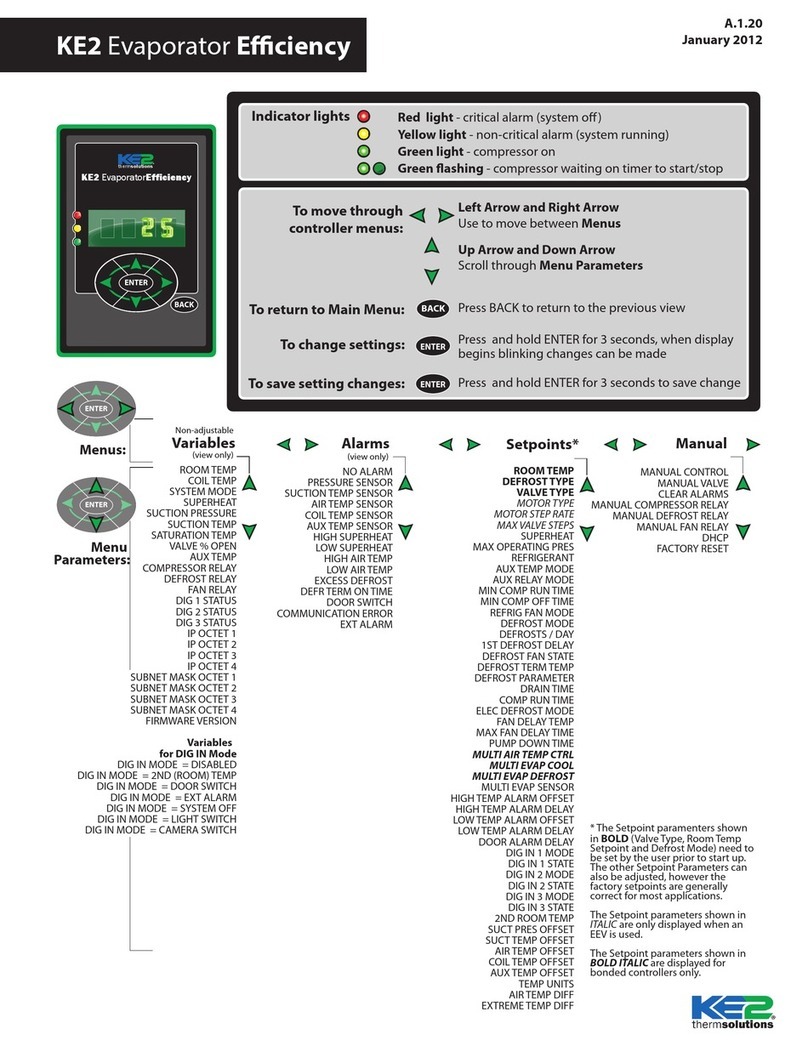

KE2 AdaptiveControl

Condensed Quick Start Guide

Press and hold

for 3 seconds

BASIC MENUS

ADVANCED MENUS

Press and hold

for 3 seconds

rtP

Clt

SySt

CPrl

dFrl

Fnrl

ALSt

Default menu -

Non Adustable (view only)

VARIABLES MENU

tS

dtyP

dFit

dPd

dFt

diF

OFFt

Runt

FrEF

AU1

StA1

AU2

StA2

tS2

tOd

d1

d2

d3

d4

d5

d6

d7

d8

d9

d10

d11

d12

dtSP

drnt

fdSP

Fndt

FndF

Pdt

HAO

LAO

tAd

Adr

Unt

CLAL

Schedule Defrost w.

Custom Defrost Per Day

tS

dtyP

dFit

dPd

dFt

diF

OFFt

Runt

FrEF

AU1

StA1

AU2

StA2

tS2

dtSP

drnt

fdSP

Fndt

FndF

Pdt

HAO

LAO

tAd

Adr

Unt

CLAL

Schedule

Defrost

tS

dtyP

dFit

dPd

dFt

diF

OFFt

Runt

FrEF

AU1

StA1

AU2

StA2

tS2

dPtr

HEtr

EdiF

dtSP

drnt

fdSP

Fndt

FndF

Pdt

HAO

LAO

tAd

Adr

Unt

CLAL

Demand

Defrost

tS

dtyP

dFit

HAO

LAO

tAd

Demand

Defrost

tS

dtyP

dFit

dPd

dFt

HAO

LAO

tAd

Schedule

Defrost

tS

dtyP

dFit

dPd

dFt

tOd

d1

d2

d3

d4

d5

d6

d7

d8

d9

d10

d11

d12

HAO

LAO

tAd

Schedule Defrost w.

Custom Defrost Per Day

dPd & dFt only

visible if ScHd

(schedule) is

selected for DFit

(defrost initiation

mode)

dPd & dFt only

visible if ScHd

(schedule) is

selected for DFit

(defrost initiation

mode)

tOd only visible if

CUS (custom) is

selected for dPd

(defrosts per day)

rtP

Clt

rt1 or Ct1 or tp1 or din1

SyOn

SyOF

drOn

drCL

diOn

diOF

dLOC

dAUt

inid

tErd

T2OF

t2On

SySt

CPrl

dFrl

Fnrl

ALSt

depending on the use

of the digital input

(din1), controller will

display one of these:

Basic Menu If Auxiliary

Input(s) Used

Accessing the Menus

© Copyright 2019 KE2 Therm Solutions, Inc., Washington, Missouri 63090

IMPORTANT:

Determine the coil sensor location

When arriving on site, put the system into defrost and

observe where the frost on the coil disappears last.

Place the coil sensors in the two places where you ob-

serve the frost disappearing last - ❶. Monitor the coil’s

air entering and air exiting side. Often the last place frost

disappears is on the air exiting side, near the right or left

end. And, it is important to verify all heating elements are

working properly.

Generally, sensor location is approximately 1 to 1-1/2”away

from the right and left edges of the active coil surface, and

typically near the bottom 1/3rd of the evaporator. Ice tends

to grow from the edges inward. The sensor needs to be as

far away from the defrost heat sources as possible. Do not

install on U-bend.

Note: To prevent sensor wire damage from sharp edges,

insert plug G into coil housing - ❷. Plug is inserted in the

inner housing to access the coil. Puncture plug to insert

sensor wire.

❸Insert the sensor into the coil so it touches two circuit

tubes, with the tip touching one of the circuit tubes. Don’t

locate it next to the heating elements - position it half way

between the heaters if possible. ❹The probe is inserted

into the ns approx. 1/16” deeper than the stainless shield-

ing. Pinch the ns gently together, securing the sensor. This

provides thermal ballast, ensuring a complete defrost.

Typically last spots to defrost

Verify by initiating a defrost,

and observing last spot to clear.

❶

Typical sensor location

approx. 1-1/2”from end,

in the bottom third of coil.

Item Gfrom Parts List on page 1

❷

▪Use the & arrows to scroll through

the available setpoints.

Indicator Lights

▪Use & to change the setpoint.

Press to move between digits to

accelerate the changes.

ENTER

ENTER

ENTER

▪Press and hold to conrm each

setpoint change

BACK

▪Press to escape.

▪Access Setpoints by pressing & holding

until tS (temp setpoint) displays

ENTER

Red light

Basic Menu - not used;

Advanced Menu - pulsing

Yellow light

non-critical alarm

(system running)

Green light

compressor on

Green ashing

compressor waiting on

timer to start/stop

ENTER

▪Press to view the current setting.

Navigation

▪

Use the & arrows to scroll through

the available setpoints.

▪Use & to change the setpoint.

Press to move between digits to

accelerate the changes.

ENTER

ENTER

ENTER

▪Press and hold to conrm each

setpoint change

BACK

▪Press to escape.

▪

Access Setpoints by pressing & holding

until tS (temp setpoint) displays

ENTER

Red light

Basic Menu - not used;

Advanced Menu - pulsing

Yellow light

non-critical alarm

(system running)

Green light

compressor on

Green ashing

compressor waiting on

timer to start/stop

ENTER

▪Press to view the current setting.

Alternate method - As the defrost termination sensor, it is

important the sensor does not terminate defrost before all

frost is removed from the coil. In some installations, insert-

ing the sensor into the coil may position it too close to the

defrost heat source. An alternate method of positioning

places the sensor vertically between the coil ns, see ❺.

Pinch ns together gently, securing the sensor ❻.

Extending sensor wires

After the sensors are mounted, route them back to the

controller. If the wires must be extended, use 18 gauge

twisted shielded pair. Max. length for 18 gauge: 100ft.

When running the sensor wires back to the controller be

careful not to introduce noise. Noise occurs when sen-

sor wires are located near high voltage lines (dened by

UL as greater than 30V.) Do not run sensor wires in the

same conduit as high voltage lines.

If crossing a high voltage line, run the sensor wiring at

right angles to minimize noise.

KE2 Therm Solutions

12 Chamber Drive . Washington, MO 63090

1-888-337-3358 . www.ke2therm.com

❹❸ ❺ ❻