PREREQUISITES

BUILDING NOTICE

When you install a stove and erect a chimney, you

may have to give building notice to the local Planning

and Building Committee. Contact the Planning and

Building Committee in your municipality for up-to-

date information.

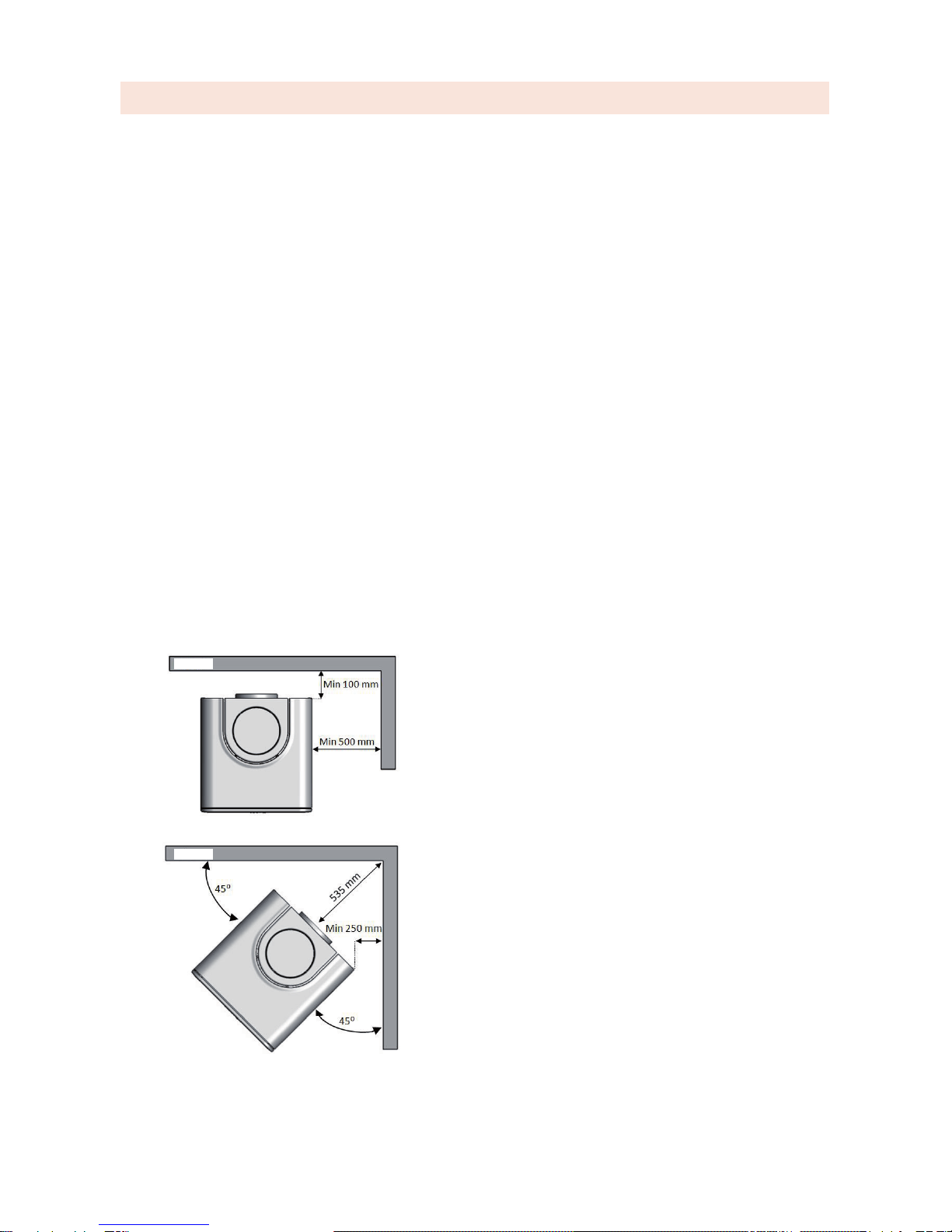

DISTANCE TO FLAMMABLE STRUCTURAL

UNITS

Before deciding where to place the stove, you must

localise the beams in the ceiling and the roof in order

to determine whether it is feasible to install a chimney

in the desired place.

The K800 must be placed at a distance of 100 mm

from ammable walls.

The distance from the side of the stove to a per-

pendicular wall must be at least 500 mm ventilated

space. (See the illustration below).

For corner placement, the minimum distance to am-

mable walls is 250 mm. This is measured at an angle

of 45 degrees from the rear corners of the stove.

(See the illustration below).

The stove may be placed closer than the dimensions

given above, if the wall is not ammable, however,

not closer than 50 mm.

LOAD-BEARING SURFACE

Check that the oor joists have sucient load-bearing

capacity. The stove and the chimney can normally be

placed on an ordinary timber joist oor, if their total

weight does not exceed 400 kg.

FLOOR PLATE

A oor plate must be set in place to protect the oor

from ying embers. The oor plate must extend at

least 300 mm in front of the door. The width of the

oor plate must be at least the width of the stove plus

100 mm on each side. An example of an approved

oor plate is given on page 5.The oor plate can con-

sist of natural stone, concrete, clinker tiles or 0.7-mm

steel plate.

Naturally, you can use Keddy's own oor plate or

oor glass. These are installed after completing the

installation of the stove.

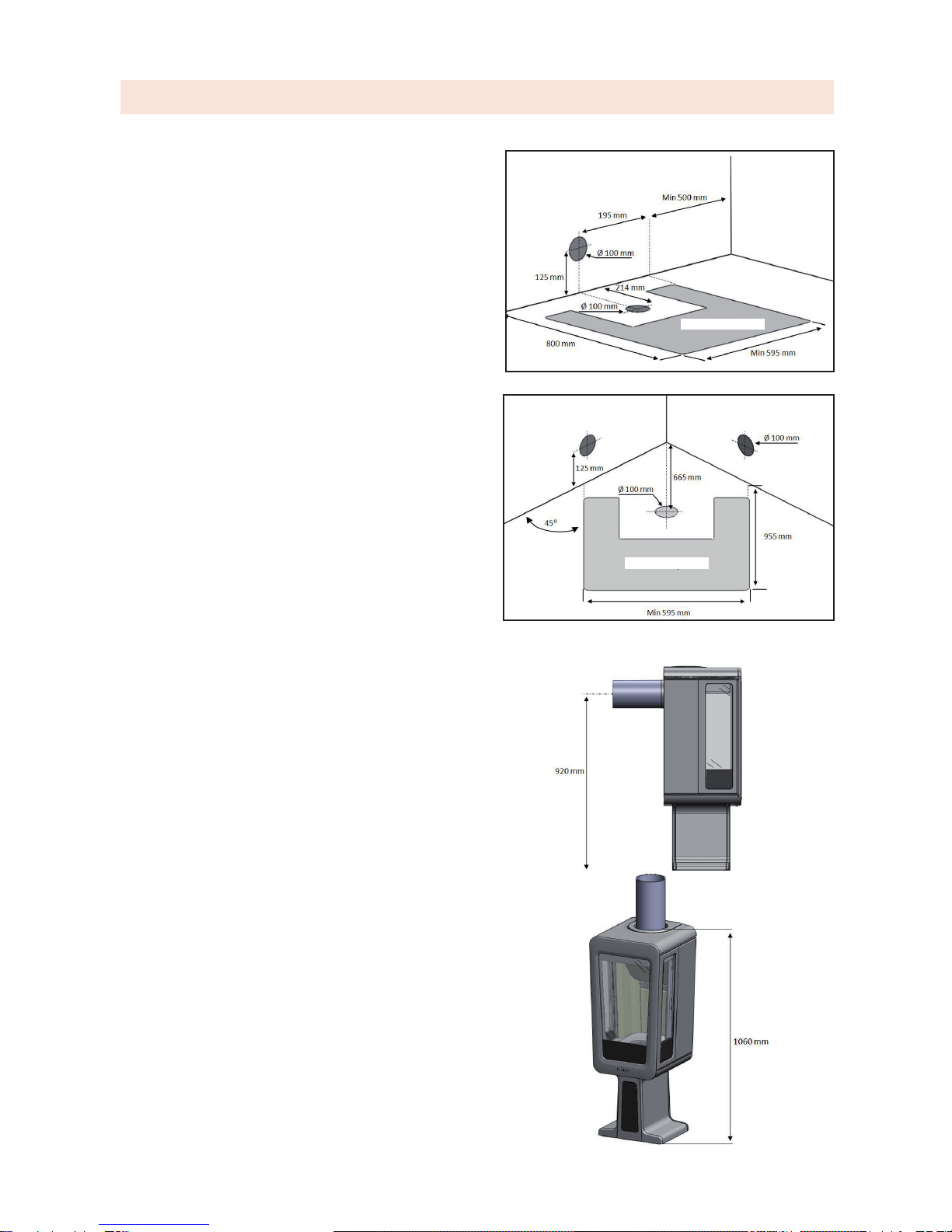

OUTDOOR AIR SUPPLY

The combustion of wood requires air/supply air. The

K800 can be provided with an external air supply,

which is recommended for properties with mechani-

cal ventilation, see also under the heading "Good to

know" on page 13.A sheet metal drum is used for

drawing an outdoor air duct. The connection diam-

eter of the supply air hose to the stove is 100 mm. If

the duct is more than 3 m long, the diameter of the

sheet metal drum must be increased to 125 mm. The

drum can be connected from below or from the rear,

see the illustration on page 5. (A stove's maximum

need for combustion air is approx. 20 m3/h).

The supply air must not be taken from crawl spaces.

If there is a crawl space, the sheet metal drum must

be extended to a valve in the foundation wall. If the

space is heated, the supply air channel must be insu-

lated against condensation.

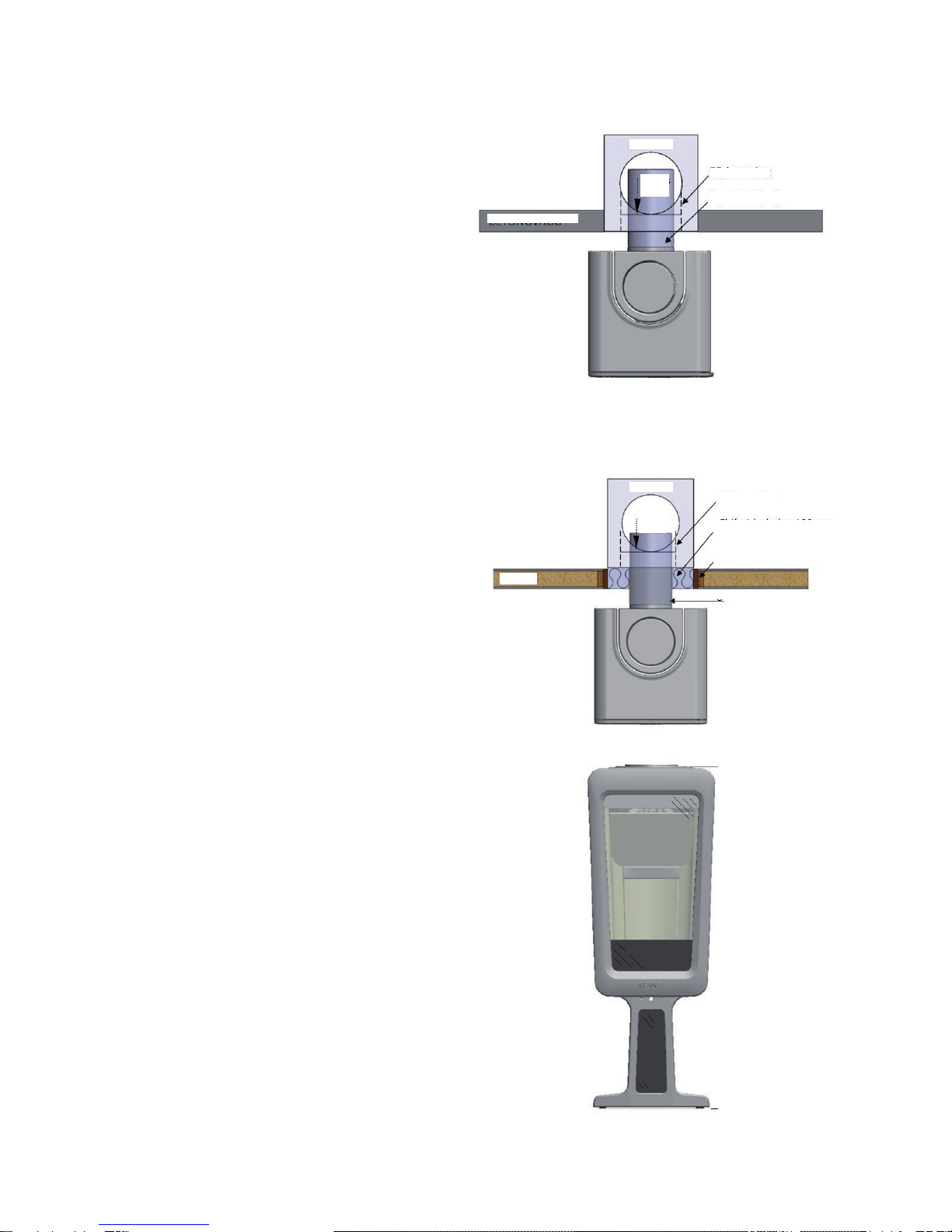

FLUE

The K800 must be connected to a ue approved

for at least 350ºC. As the area, length and material

of the ue are of great importance for the draught

formed in the ue, it is important the ue is not under-

dimensioned.The minimum recommended chimney

length is 3500 mm, measured from the top of the

stove, and the suitable area is 150 - 200 cm2 (approx.

150 mm in diameter.

Naturally, the K800 can also be connected to chim-

neys made of prefabricated elements, e.g. the Heda

Chimney.

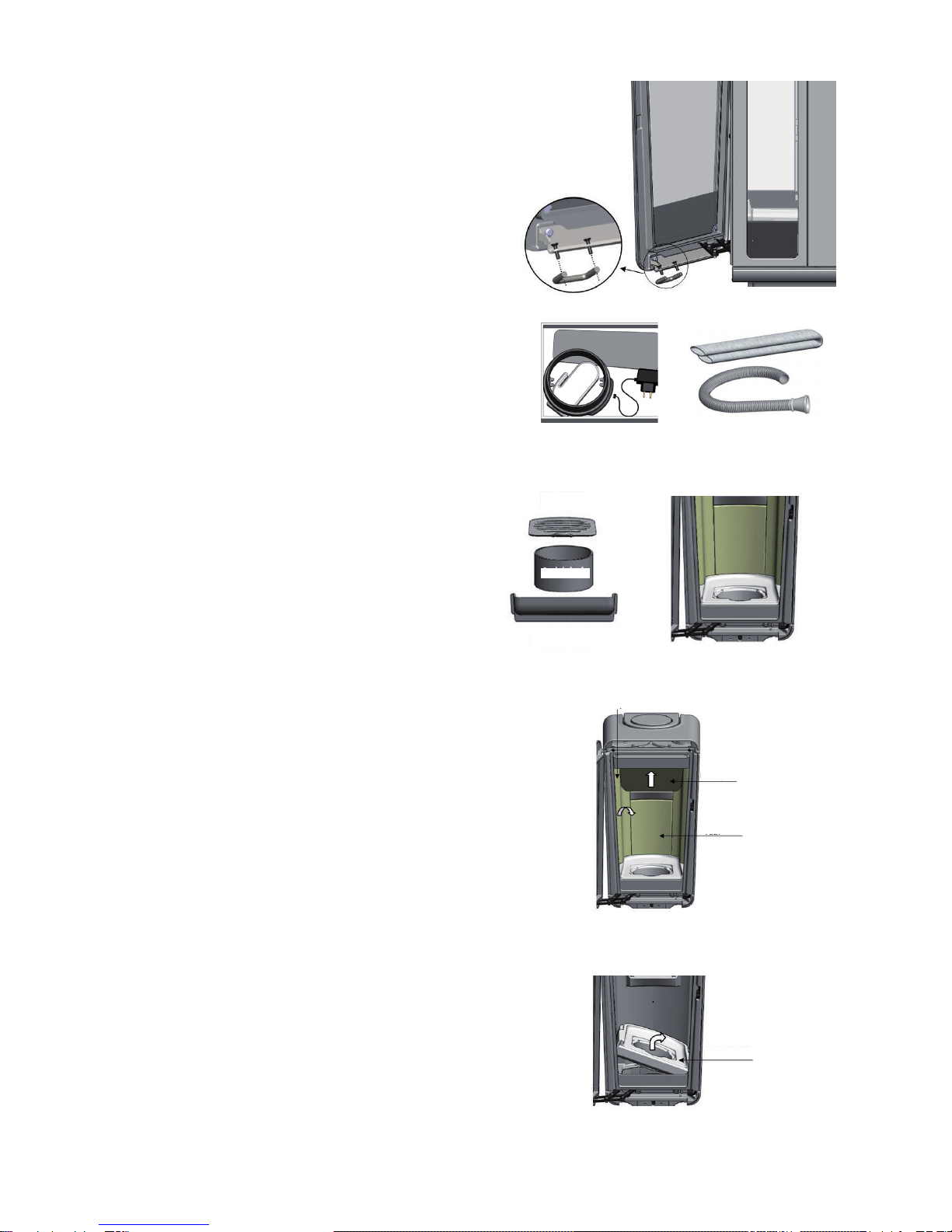

CHIMNEY CONNECTIONS

The illustration on page 5 shows the K800 from

above as well as where the ue ends up in relation

to the wall, depending on the choice of placement.

There is an illustration on page 6 for connection to an

existing ue.

Read the chimney's installation instructions before

starting on the preparations for the chimney and its

connection.

- 4 -

WALL

WALL