CONTENTS

Slim Jim User manual page 1

Designation............................................................................................................................................ 2

Precaution.............................................................................................................................................. 2

Safe operation........................................................................................................................................ 2

Water Quality ......................................................................................................................................... 3

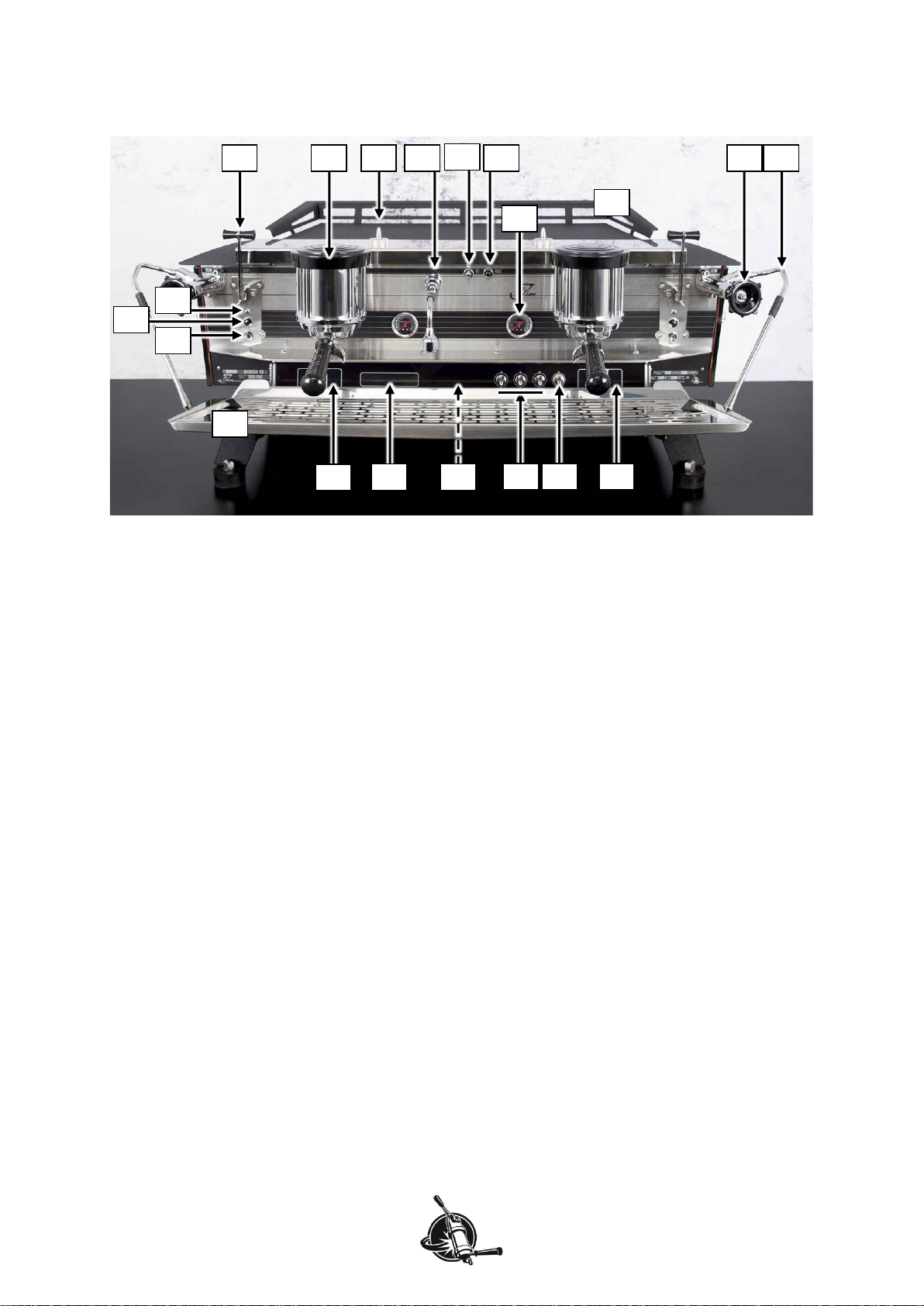

Parts identification ................................................................................................................................ 4

Operational features.............................................................................................................................. 5

MAIN switch......................................................................................................................................... 5

HEAT switches .................................................................................................................................... 5

Circuit breakers ................................................................................................................................... 5

Bastone unit......................................................................................................................................... 6

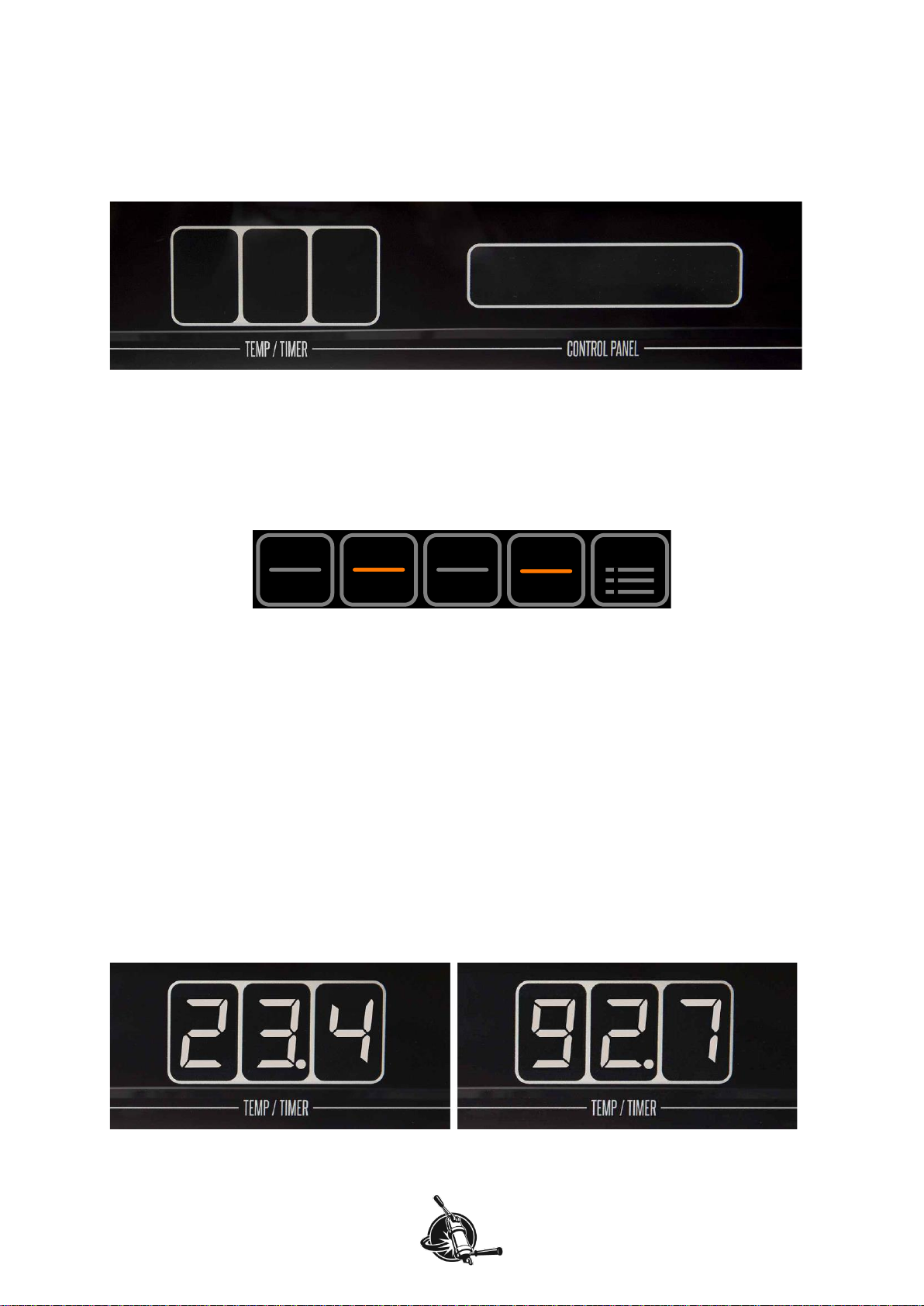

Touchpad............................................................................................................................................. 6

Temperature display............................................................................................................................ 7

Shot time.............................................................................................................................................. 7

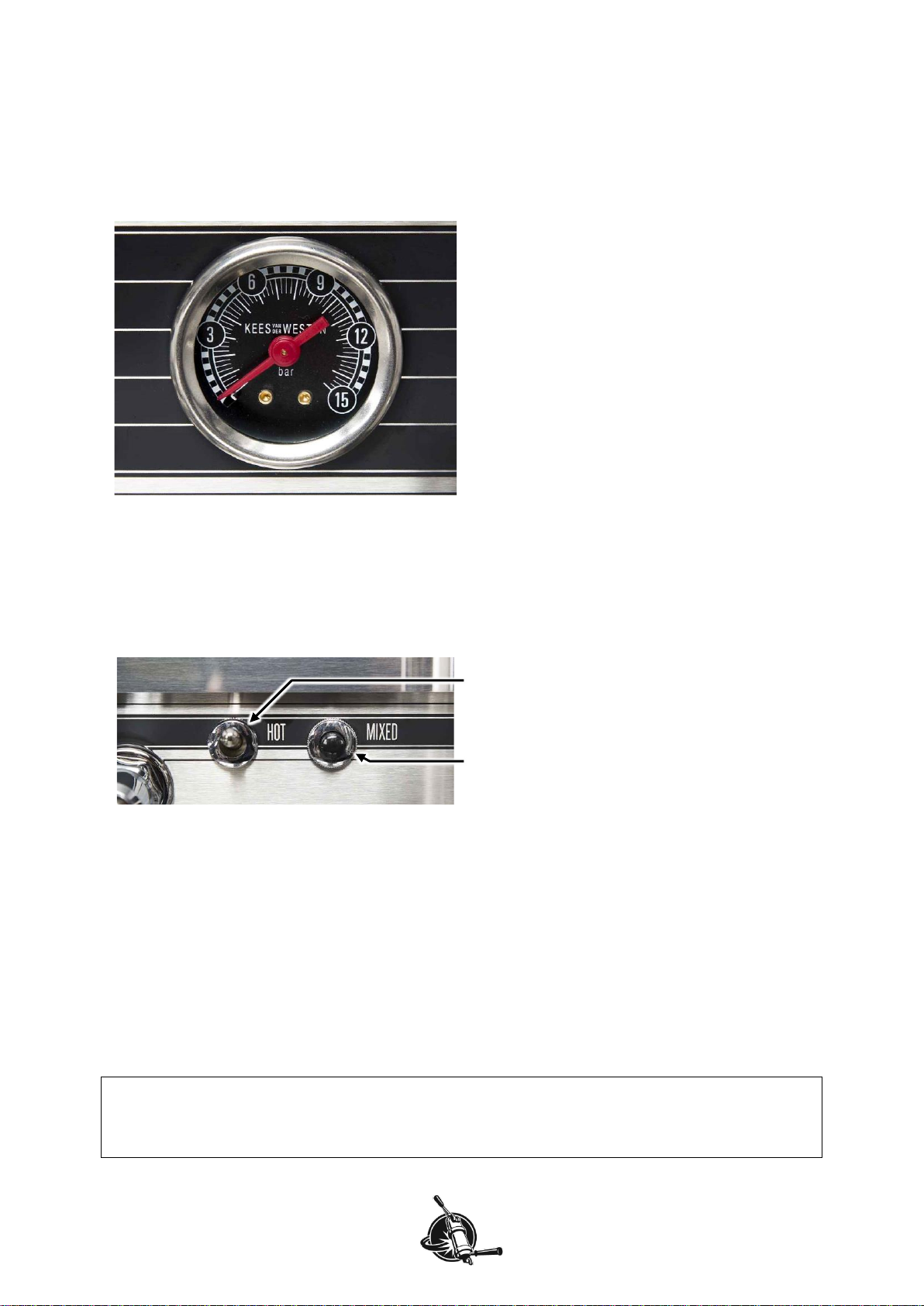

Pressure gauge ................................................................................................................................... 8

Dispensing hot water........................................................................................................................... 8

Steaming.............................................................................................................................................. 9

Pre-infusion cylinder............................................................................................................................ 9

Control panel ....................................................................................................................................... 10

Change individual boiler to ECO and back........................................................................................ 10

Go to stand-by................................................................................................................................... 11

Sensor malfunction............................................................................................................................ 12

Technical assistance......................................................................................................................... 12

Start automatic back-flush program .................................................................................................. 13

Flow meter error ................................................................................................................................ 13

Use external temperature sensor (option)......................................................................................... 14

Program volumes with touchpad or Bastone..................................................................................... 15

Change settings in the Barista menu................................................................................................ 16

Sub-menu TEMPERATURE SETTING............................................................................................. 17

Sub-menu VOLUME SETTING......................................................................................................... 17

Sub-menus TIMED ON/OFF and TIME/DATE.................................................................................. 18

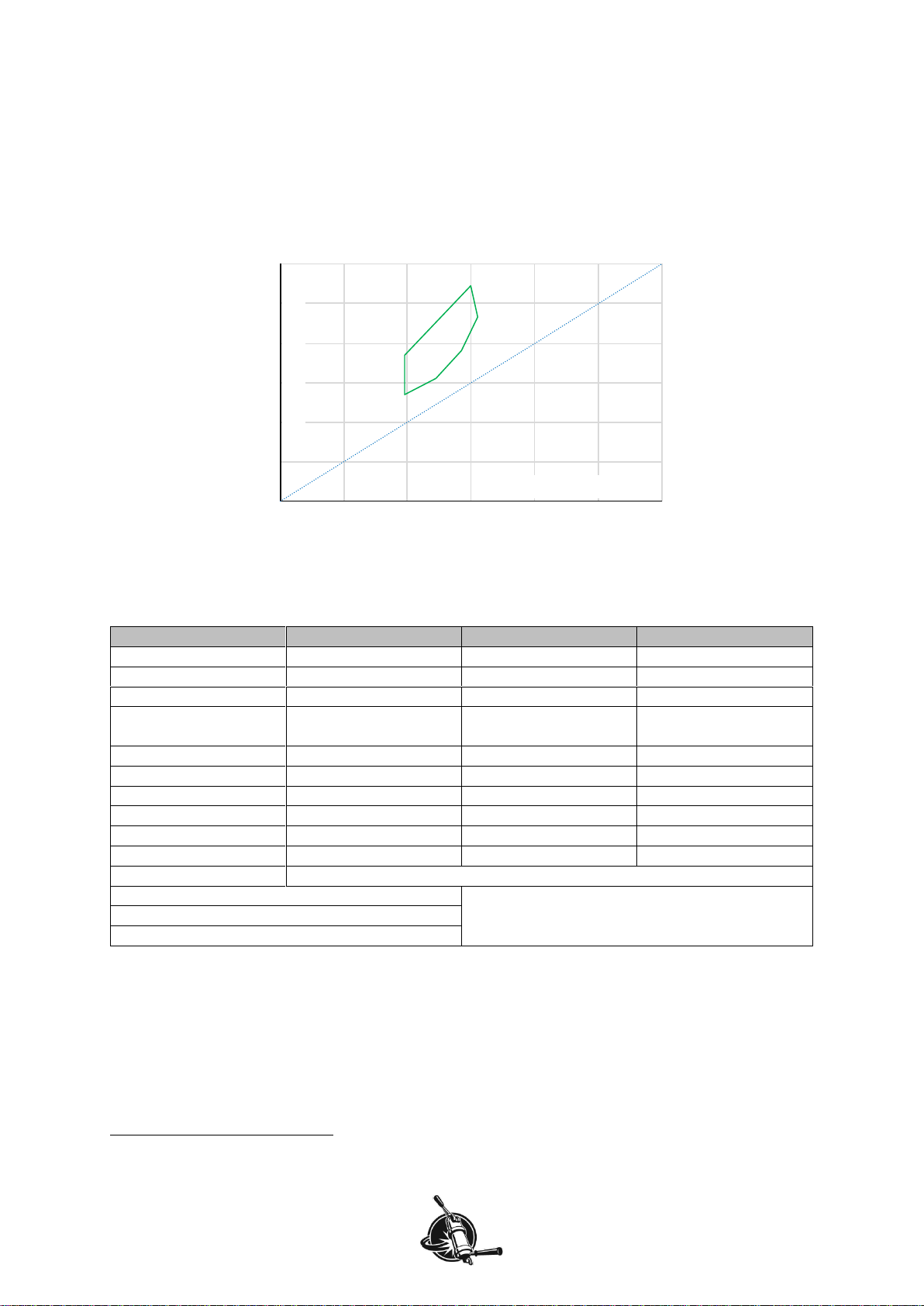

Pump-pressure .................................................................................................................................... 19

Check................................................................................................................................................. 19

Adjust................................................................................................................................................. 20

Machine cool-down ............................................................................................................................. 20

Daily to weekly maintenance.............................................................................................................. 21

Use hot water from the machine ....................................................................................................... 21

Clean body ........................................................................................................................................ 21

Clean steam wand............................................................................................................................. 21

Remove filter basket.......................................................................................................................... 21

Clean filter holder .............................................................................................................................. 22

Back flush group................................................................................................................................ 22

Clean group screen, check and replace group seal.......................................................................... 23

Clean group dispersion plate............................................................................................................. 24

Replace dispersion base and plate ................................................................................................... 25

Descaling........................................................................................................................................... 25

Check machine condition, report malfunctions............................................................................... 26

Free-flowrate ..................................................................................................................................... 26

Heating element indicator lights ........................................................................................................ 26

Check pressure gauges..................................................................................................................... 27

Opening pressure of expansion valve............................................................................................... 27

Consistency in programmed volumes ............................................................................................... 27

External temperature probe (option) ................................................................................................. 28

Recommended maintenance and service scheme .......................................................................... 29

Service Record .................................................................................................................................... 30

Contact information ............................................................................................................................ 32