Mirage technical manual page 1 of 65

Contents

Precaution.............................................................................................................................................. 2

Advice for installation personnel......................................................................................................... 2

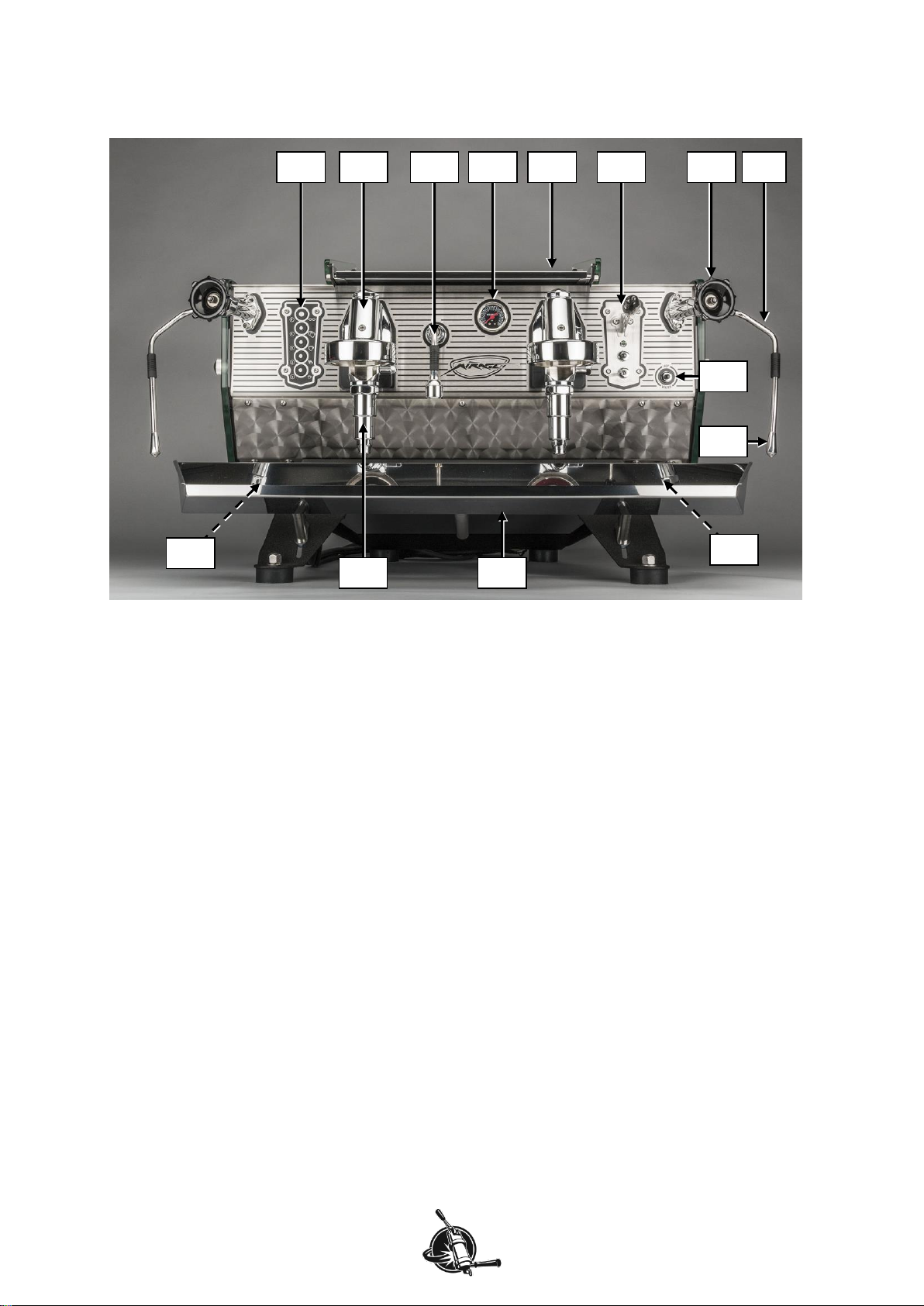

Parts identification ................................................................................................................................ 3

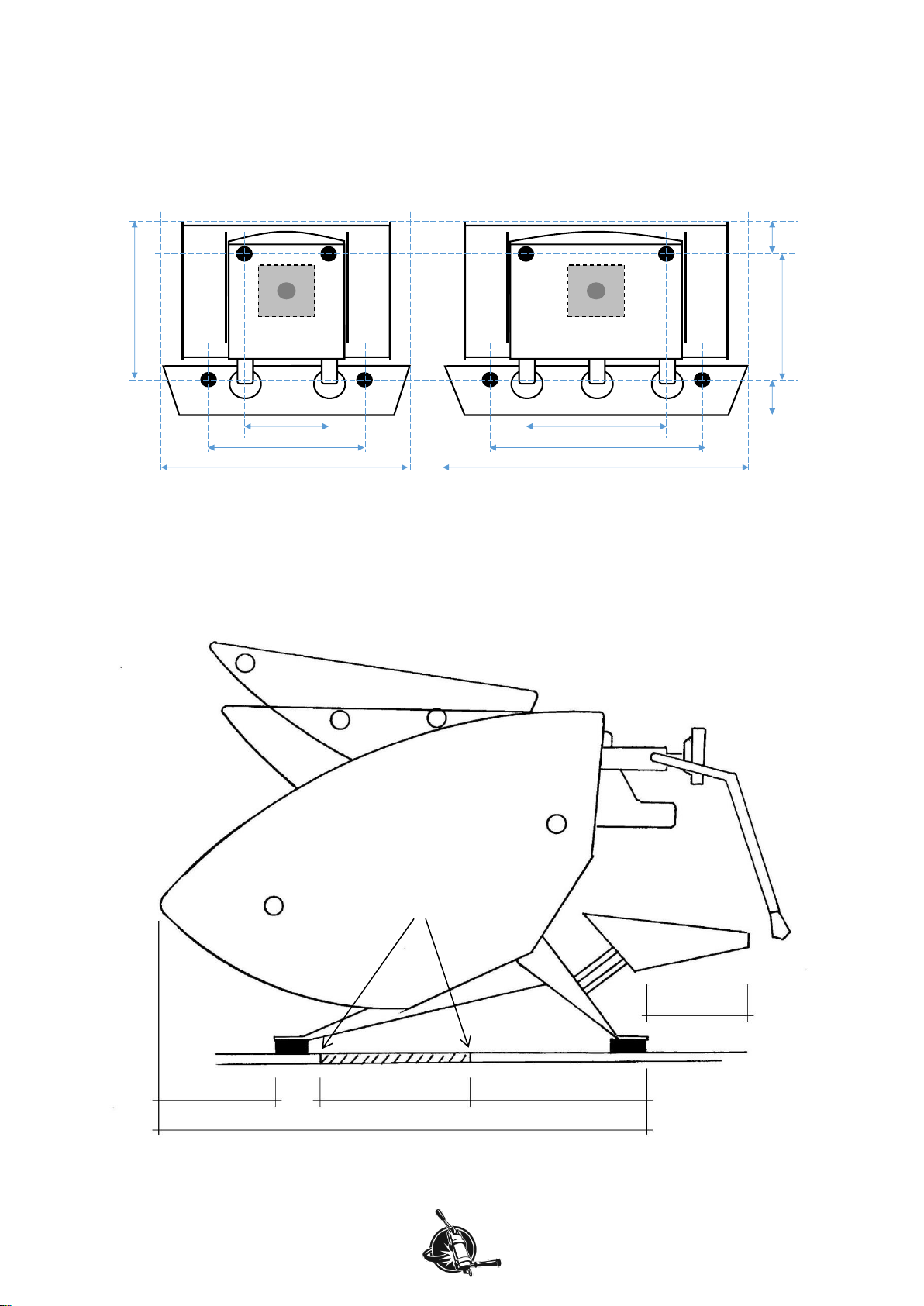

Dimensions ............................................................................................................................................ 4

Footprints............................................................................................................................................. 4

Silhouette............................................................................................................................................. 4

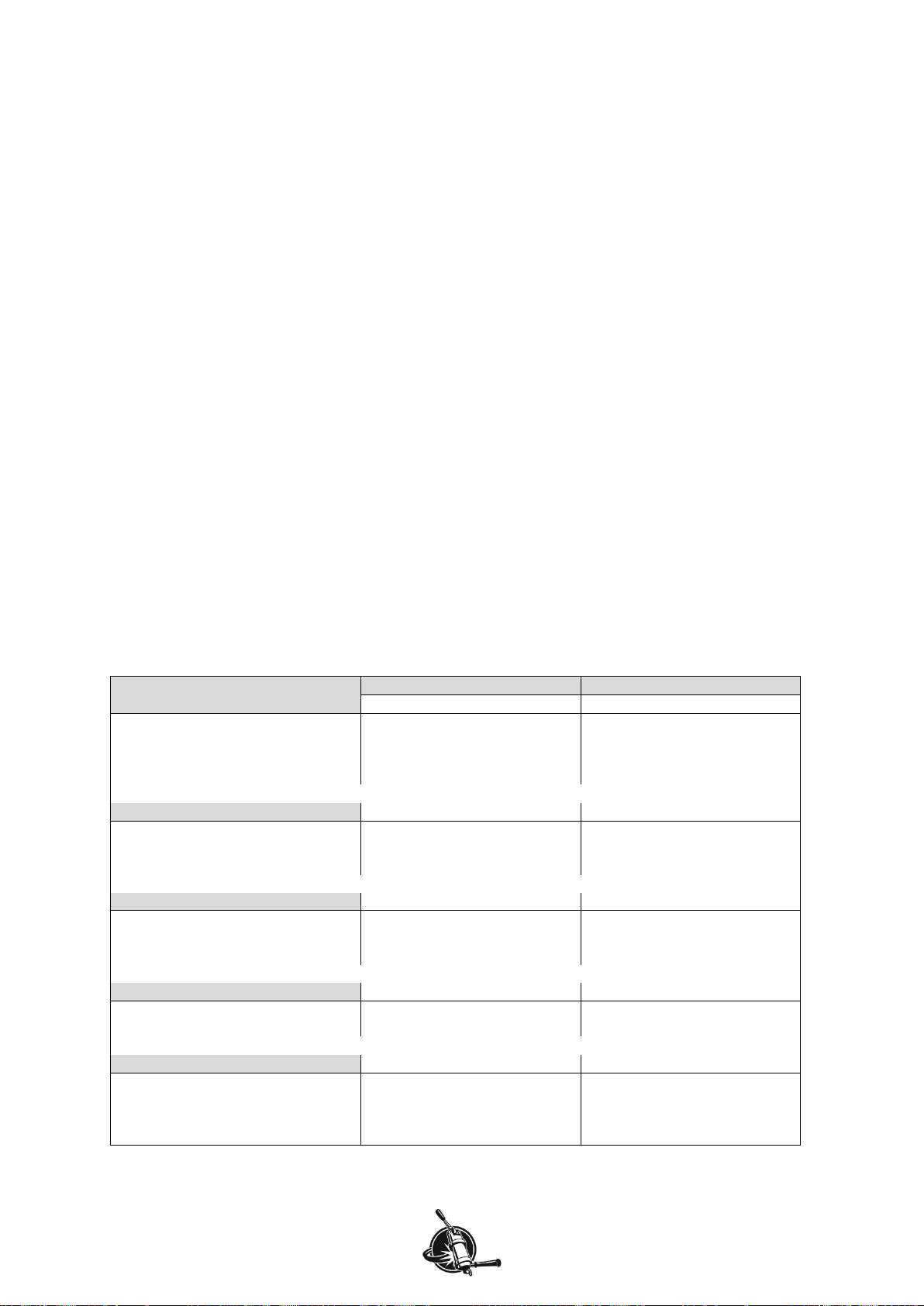

Main characteristics.............................................................................................................................. 5

Abridged machine performance .......................................................................................................... 6

Notice.................................................................................................................................................... 10

Water quality........................................................................................................................................ 11

Note on this manual ............................................................................................................................ 12

Maintenance......................................................................................................................................... 13

Handy items while performing maintenance ..................................................................................... 14

Remove body panels......................................................................................................................... 16

Boiler temperature vs steam power................................................................................................... 19

Adjust brew temperature ................................................................................................................... 21

Adjust pump pressure........................................................................................................................ 23

Check water treatment system.......................................................................................................... 24

Anti-vacuum valve............................................................................................................................. 25

Grease wands and check play between nut and ball........................................................................ 27

Check tubing from mix-block to fitting for scale build-up................................................................... 29

Check restrictor in mix-block on scale build-up................................................................................. 30

Safety valve on steam boiler ............................................................................................................. 32

Expansion valve on manifold............................................................................................................. 34

Rebuild valves ................................................................................................................................... 37

Clean probes, level and safety.......................................................................................................... 39

Replace all solenoid valves............................................................................................................... 41

Drain all water when freezing is possible.......................................................................................... 46

Technical information ......................................................................................................................... 48

Electric scheme Mirage 1-phase, Duette .......................................................................................... 48

Electric scheme Mirage 3-phase: Duette high power/Triplette.......................................................... 49

Level control and water meters ......................................................................................................... 50

Mains switch Duette .......................................................................................................................... 50

Mains switch Duette high power/Triplette.......................................................................................... 51

Triplette connector block: 3-phase or 1-phase.................................................................................. 52

Problem solving................................................................................................................................... 53

Controller........................................................................................................................................... 53

Steam boiler temperature controller.................................................................................................. 55

Solid state relay................................................................................................................................. 57

Heating element ................................................................................................................................ 61

Heating element seal......................................................................................................................... 64

More information on our website....................................................................................................... 65

Contact information ............................................................................................................................ 65