CONTENTS

Slim Jim Installation manual page 1

Designation............................................................................................................................................ 2

Safe operation........................................................................................................................................ 2

Installation manual................................................................................................................................ 3

Parts identification ............................................................................................................................... 3

Installation summary............................................................................................................................ 4

Check location................................................................................................................................. 4

Unpack............................................................................................................................................. 4

Install machine................................................................................................................................. 4

Transfer machine to owner/user...................................................................................................... 4

Water Quality....................................................................................................................................... 5

Water supply........................................................................................................................................ 6

Water treatment system ...................................................................................................................... 6

Waste/drain ......................................................................................................................................... 6

Machine location.................................................................................................................................. 6

Counter surface................................................................................................................................... 6

Pump location...................................................................................................................................... 6

Electric mains ...................................................................................................................................... 7

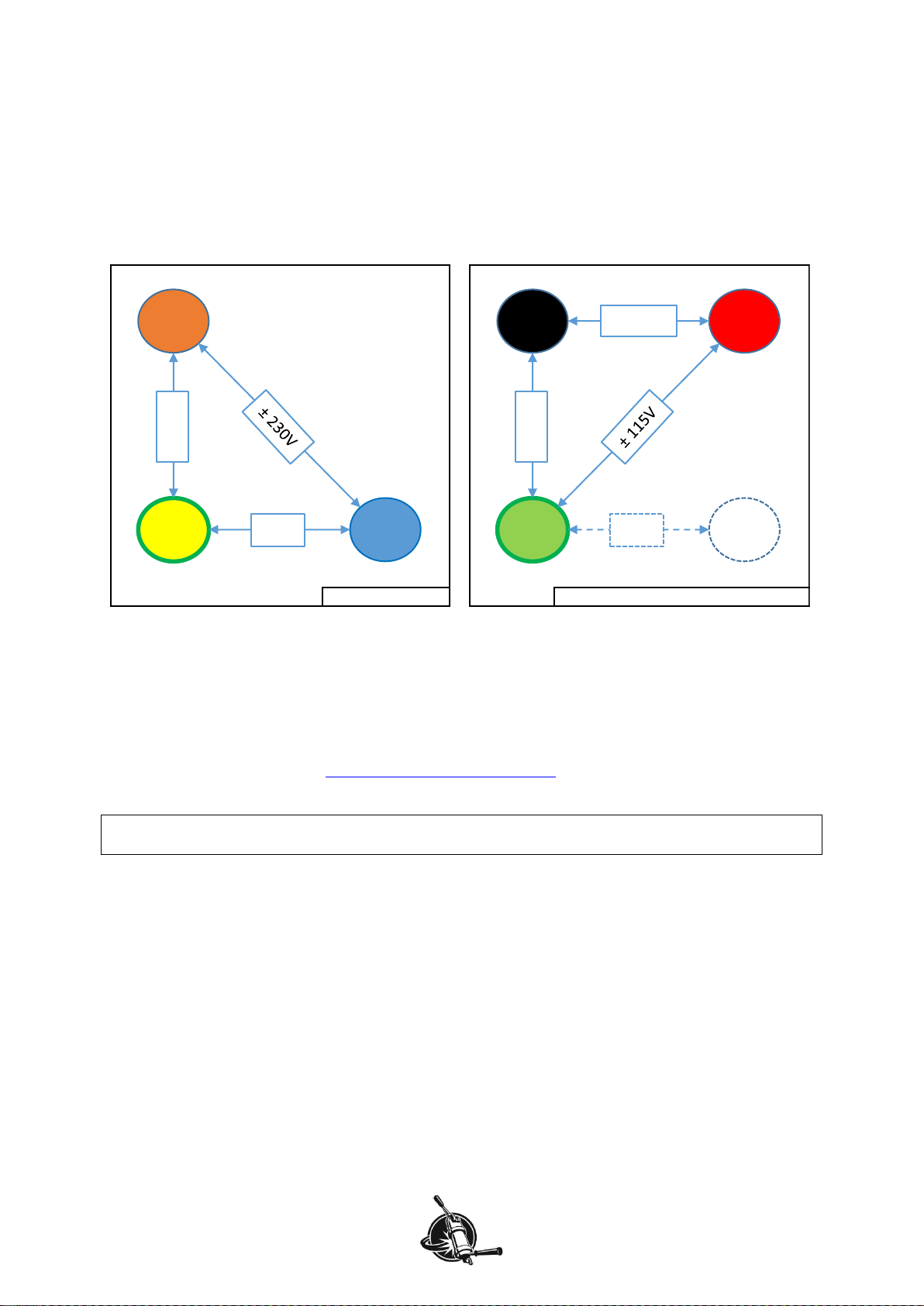

3-phase machine............................................................................................................................. 7

single-phase machine...................................................................................................................... 8

3-phase / single phase conversion.................................................................................................. 8

Unpack................................................................................................................................................. 9

Connect to water supply.................................................................................................................... 10

Connect to drain/waste...................................................................................................................... 11

Connect pump cable.......................................................................................................................... 11

Connect electric mains ...................................................................................................................... 12

First fill.................................................................................................................................................. 13

Heat up.................................................................................................................................................. 15

Adjust mix-water temperature............................................................................................................ 19

Hand over machine ............................................................................................................................. 21

Maintenance......................................................................................................................................... 23

Contact information ............................................................................................................................ 23