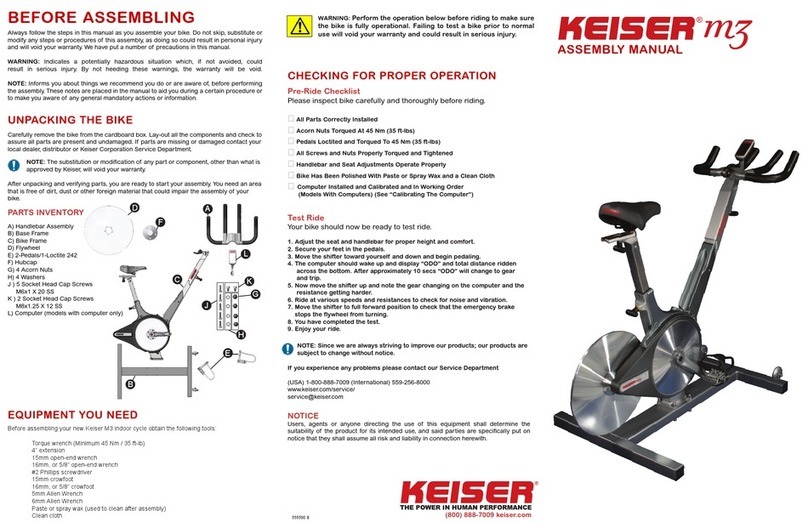

Keiser m3 TBT User manual

Other Keiser Exercise Bike manuals

Keiser

Keiser M3i lite User manual

Keiser

Keiser M3 User manual

Keiser

Keiser REAR WHEEL DRIVE BIKE User manual

Keiser

Keiser M3 User manual

Keiser

Keiser M3X User manual

Keiser

Keiser M3 Troubleshooting guide

Keiser

Keiser M3i lite User manual

Keiser

Keiser M SERIES Installation and operating instructions

Keiser

Keiser M SERIES Installation and operating instructions

Keiser

Keiser M3 User manual

Popular Exercise Bike manuals by other brands

Sunny Health & Fitness

Sunny Health & Fitness SF-B121021 user manual

Monark

Monark 827E instruction manual

Stamina

Stamina 1310 owner's manual

American Fitness

American Fitness SPR-BK1072A owner's manual

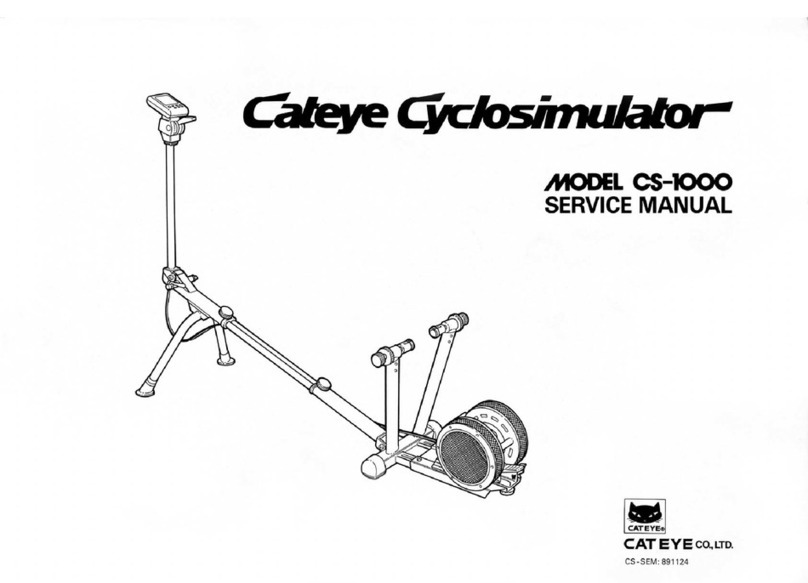

Cateye

Cateye CS-1000 (CYCLO SIMULATOR) Service manual

BH FITNESS

BH FITNESS H9158H Instructions for assembly and use