PRE-ASSEMBLY INSTRUCTIONS

PRE-ASSEMBLY INSTRUCTIONS.......................................................1

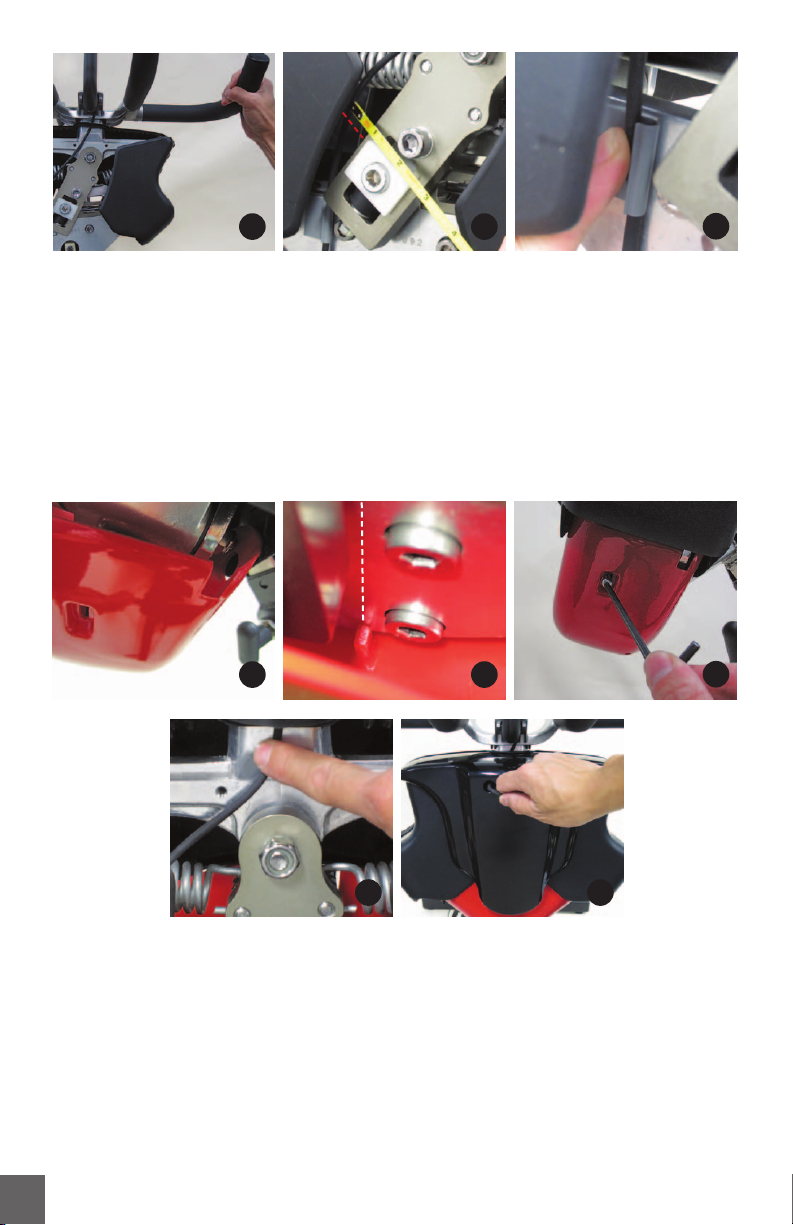

ASSEMBLY INSTRUCTIONS...............................................................4

X-BAR INSTALLATION.........................................................................6

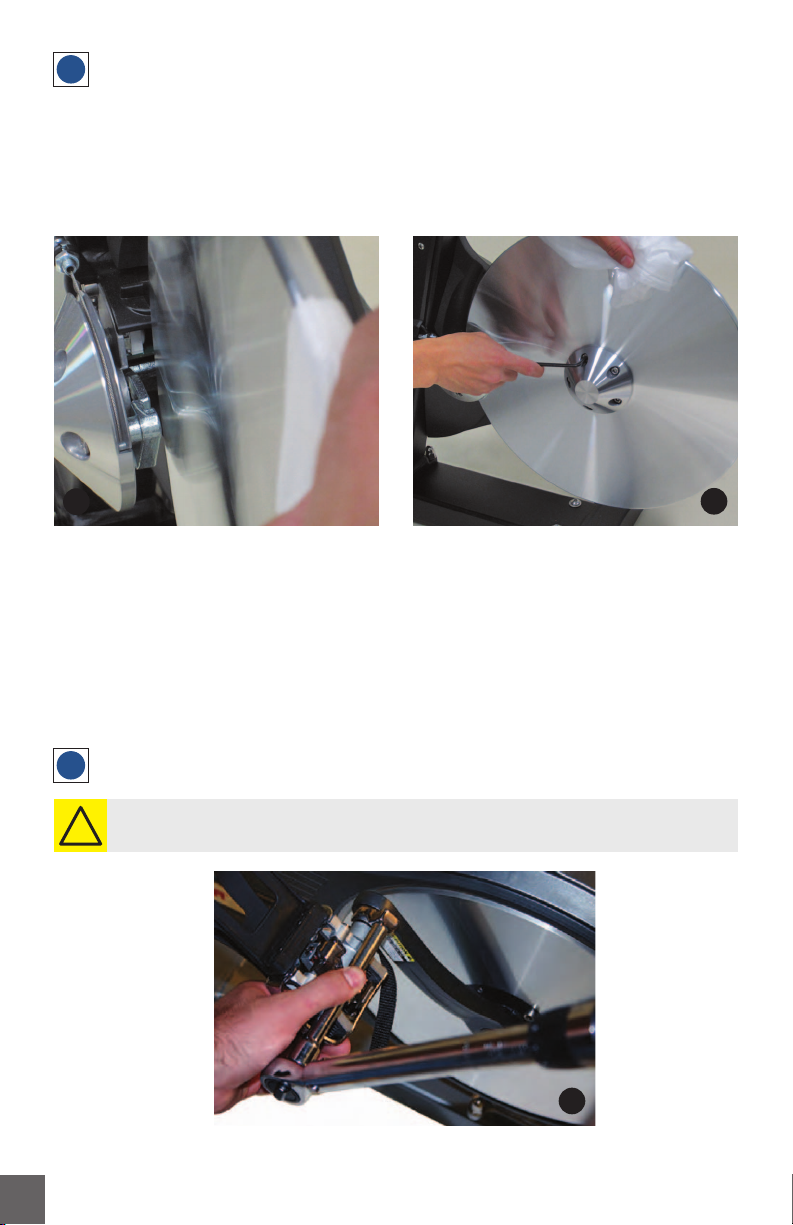

FLYWHEEL GUARD INSTALLATION.................................................10

CHECKING FOR PROPER OPERATION............................................11

SAFETY INFORMATION AND INSTRUCTIONS.................................12

COMPUTER OVERVIEW....................................................................13

CALIBRATION INFORMATION...........................................................14

PREVENTITIVE MAINTENANCE CHART............................................15

WARRANTY TERMS .........................................................................16

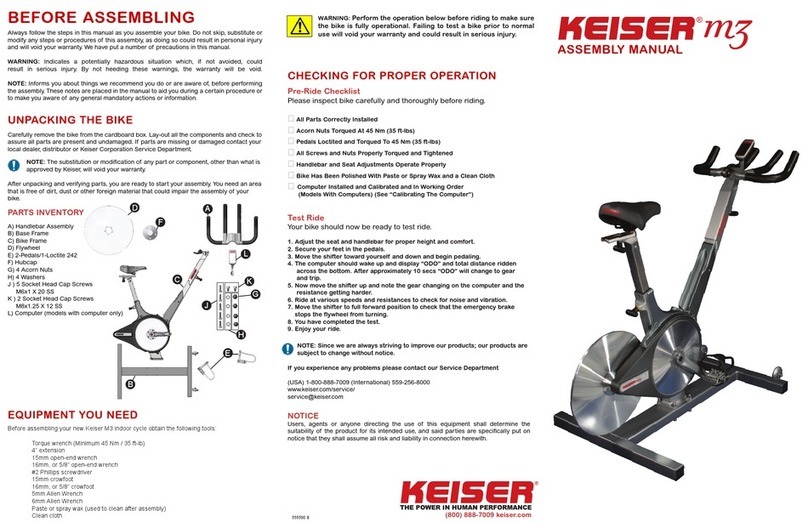

BEFORE ASSEMBLING

Always follow the steps in this manual as you assemble your M3X. Do not skip, substitute or

modify any steps or procedures of this assembly, as doing so could result in personal injury and

will void your warranty. We have put a number of precautions in this manual.

WARNING: This symbol appearing throughout this manual means PAY ATTENTION! BE

ALERT! When you see this warning symbol, your safety is involved. It is being used to call

attention to POTENTIAL hazards that could result in personal injury or loss of life.

!

NOTE: Informs you about things we recommend you do or are aware of, before performing the

assembly. These notes are placed in the manual to aid you during a certain procedure or to

make you aware of any general mandatory actions or information.

!

UNPACKING THE M3X

Carefully remove the M3X from the cardboard box. Lay-out all the components and check to

assure all parts are present and undamaged. If parts are missing or damaged, contact your local

dealer, distributor or Keiser Corporation Service Department. After unpacking and verifying parts,

you are ready to start your assembly. You need an area that is free of dirt, dust or other foreign

material that could impair the assembly of your M3X.

Torque wrench (Minimum 45 Nm / 35 ft-lb) 16mm, or 5/8” crowfoot

4” extension

13mm Combination Wrench

3mm Allen Wrench

15mm open-end wrench

4mm Allen Wrench

16mm, or 5/8” open-end wrench

#2 Phillips screwdriver

5mm Allen Wrench

6mm Allen Wrench

Paste or spray wax (used to clean after assembly)

Clean cloth

LPS #3 Heavy Duty Rust Inhibitor w/straw

Socket Wrench/Ratchet

15mm crowfoot

2 x 10mm Wrenches

10mm Socket

TOOLS YOU WILL NEED

NOTE: The substitution or modification of any part or component, other than what is approved

by Keiser, will void your warranty.

!

1