Chapter 1 INTRODUCTION

This manual explains procedures for installing the KEITH®Running Floor II®unloading

system. Many variables affect the installation, but the general process remains

constant. Details of the installation vary according to trailer features, kit selections, and

installer preferences. Optional sets of instructions are given for some operations to

allow for flexibility.

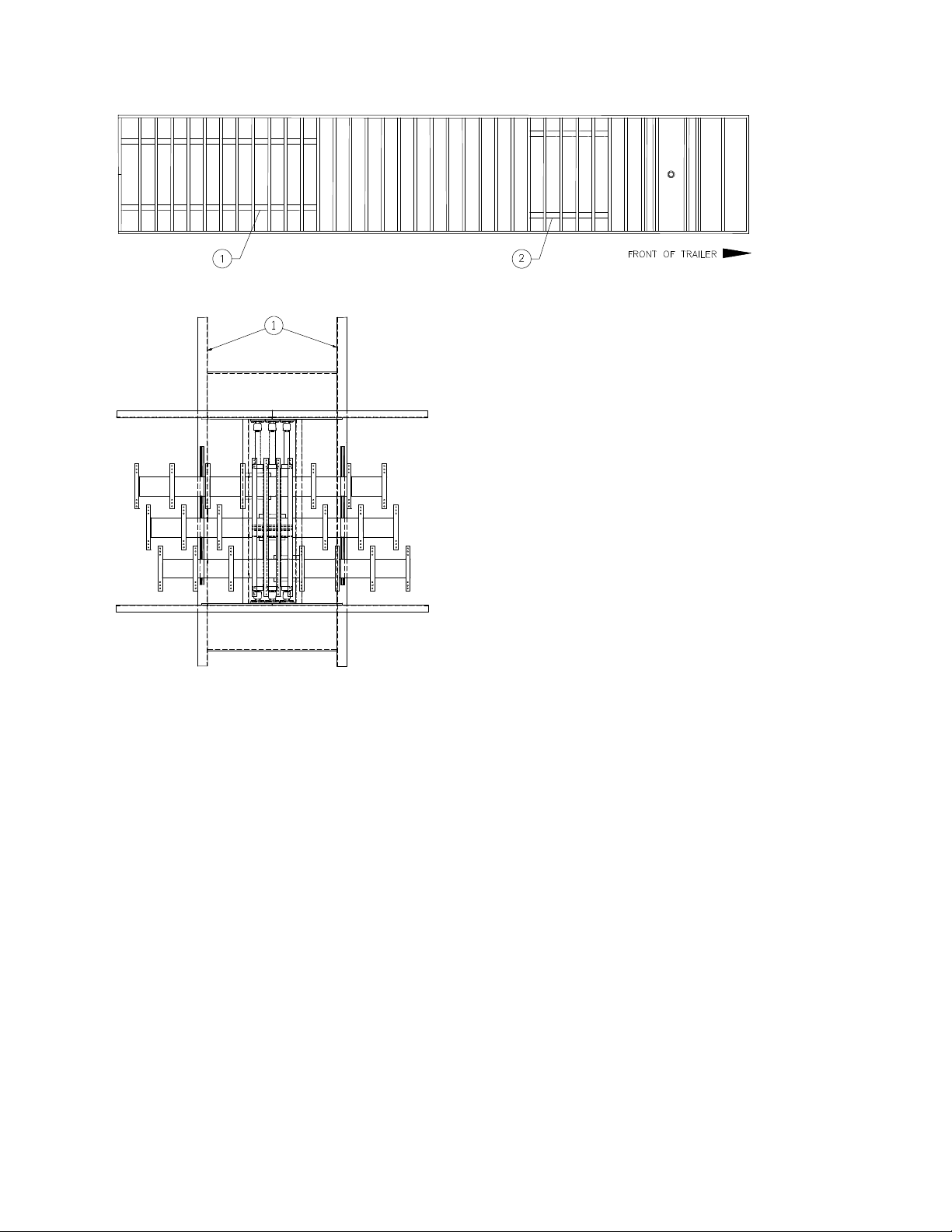

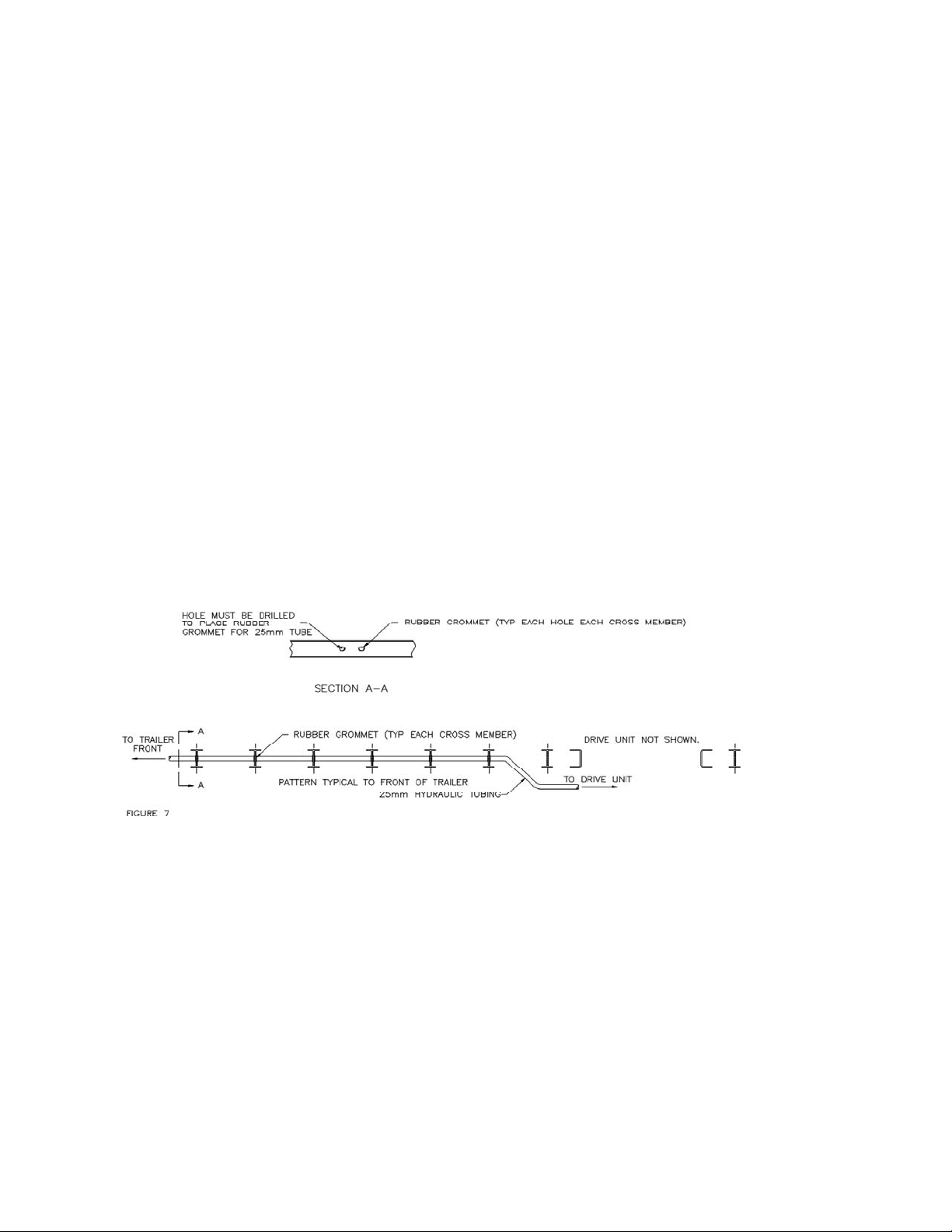

This manual focuses on the installation of an 200mm stroke system with 3 1/2"

(88.9mm) flooring. Installation of the system with 6" flooring is similar. Information

unique to 6" (152.4mm) flooring is included where it pertains.

Installation time varies and is between 35 and 100 hours, depending upon the

experience of the installer and the adaptability of the trailer. If the trailer is not yet built,

there are some trailer preparations found (Chapter 2) that will save time and effort. One

person with welding skills can complete the entire installation.

An efficient installation requires appropriate tools and accessible materials. A list of

tools is found in Appendix 1. Appendix 2 lists materials. Several reference drawings

accompany this manual. The KEITH Running Floor II owner's manual contains more

detailed information about the system and operation procedures.

Direct any questions to KEITH Mfg. Co. or one of our international offices listed on the

cover of this manual.

WARNING: Installing the WALKING FLOOR®system will require some alterations to

your trailer. Changes made without approval of the trailer manufacturer may void the

trailer's warranty.