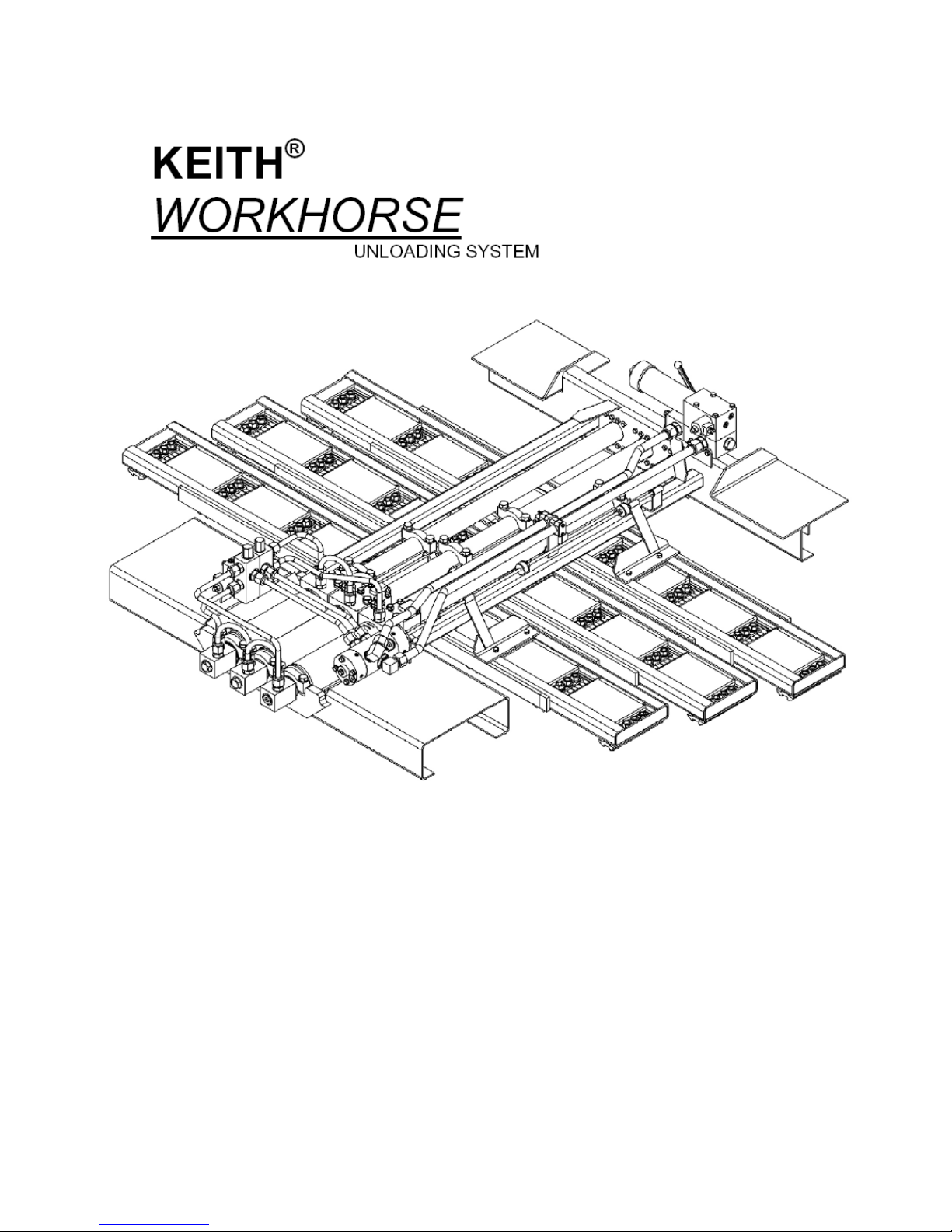

8

The KEITH®WALKING FLOOR® Workhorse System is designed for a recommended maximum oil ow of 110

l/minute. And a recommended maximum speed of 2.6 m/min.

A high power take-o (PTO) ratio (greater than 1:1) reduces the size of the pump for a given rotational speed.

This is generally the best alternative, technically as well as nancially. Compare the performance of the motors

in order to be certain that the motor can drive the pump. Also, check that the rotational speed of the motor will

not be greatly reduced by the load. Compare the maximum permitted loading of the PTO with that of the pump.

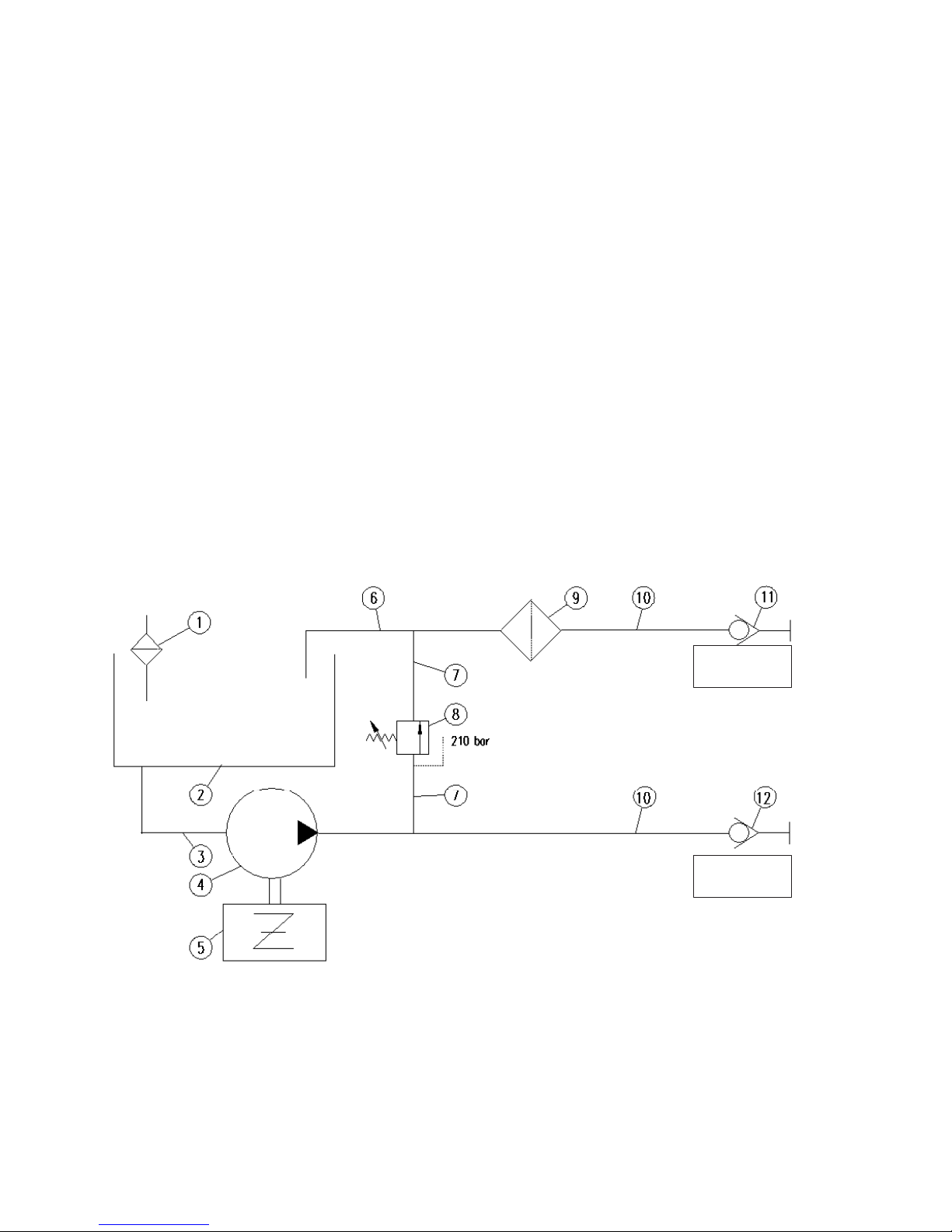

OIL:

The hydraulic oil must be of high quality, suitable for a pressure of 210 bar. The ISO viscosity must be 46

(for example Chevron AW 46 hydraulic oil), while in cold conditions a viscosity of 32 must be used.

Conditions of extreme cold demand hydraulic uids of aviation quality.

RESERVOIR:

The volume of oil in the reservoir must be equal to or greater than the oil ow per minute.

The reservoir must be lled to a level of 80-90%. Suction and return tubing must be placed so that cavitations

will be prevented. The ller cap must have a bleed capability.

PRESSURE RELIEF VALVE:

The hydraulic installation must have a pressure relief valve that is adjusted to 210 bar. Ensure that the

pressure relief valve is capable of sustaining the oil ow.

WARNING:The correct adjustment of the pressure relief valve is very important. If this is too low it is possible

that the system will not load or unload; if it is too high, the system may be damaged.

Measures to follow:

FILTER:

The lter in the return tubing must have a degree of ltration of 10 microns. In conditions of extreme cold it

is better to use ltration of 25 microns. Ensure that the nominal ow volume of the lter is the same as the

maximum oil ow that can occur in the system.

HYDRAULIC PLUMBING:

All hoses must be suitable for a pressure of at least 300 bar.

Suction Plumbing: in order to prevent cavitations, the oil ow to the suction inlet of the pump must be

unhindered. This requires suction tubing with a sucient diameter (at least 2” or 50 mm) that is as short as

possible (not more than 1.5 m), with out constrictions. Cavitations can also be caused by bends or elbows in

the pipe work – a straight line is best. Ensure that the hose cannot collapse with the suction.

Pressure plumbing: the hose from the tractor to the trailer must be 1” or 25 mm.

Return plumbing: the hose from the trailer to the lter must also be 1” (25 mm). The hose from the return lter

to the reservoir must be at least 1¼” (32 mm).

QUICK-COUPLINGS:

Tractor: Male on return (to the reservoir)

female on pressure (from the pump)

Trailer: female on return (from the “TANK” port on the lter block)

male on pressure (to the “PUMP” port on the lter block)