2 DOC06452 Rev. A

INSTALLATION MANUAL KICD - Container Drive

2.0 Container Preparations

The container requires preparation before the system is installed. Planning ahead for the WALKING

FLOOR® installation requirements saves signicant preparation time,

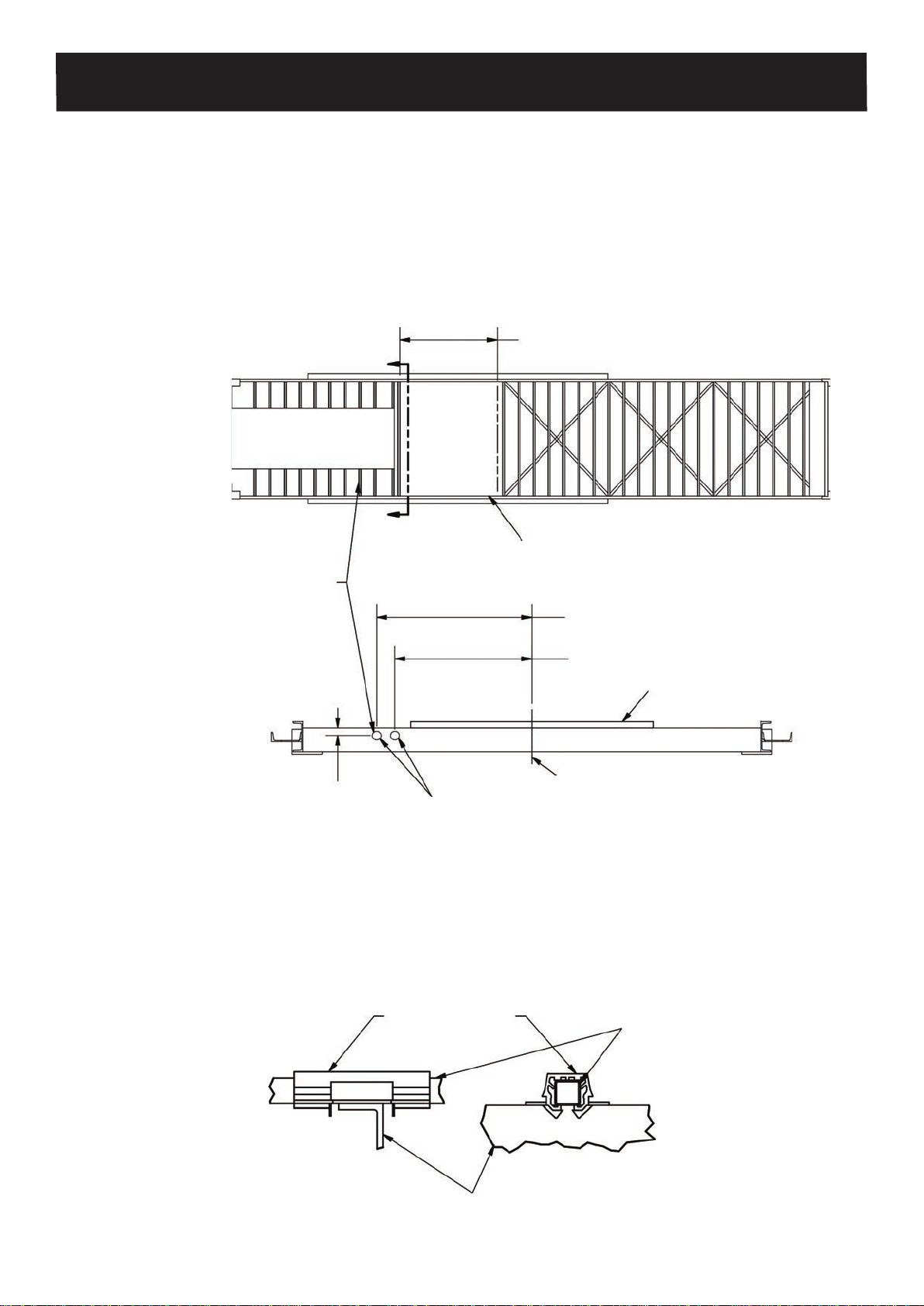

2.1 Container Alignment

Check the compatibility of the drive unit with the container before making any alterations to the

container.

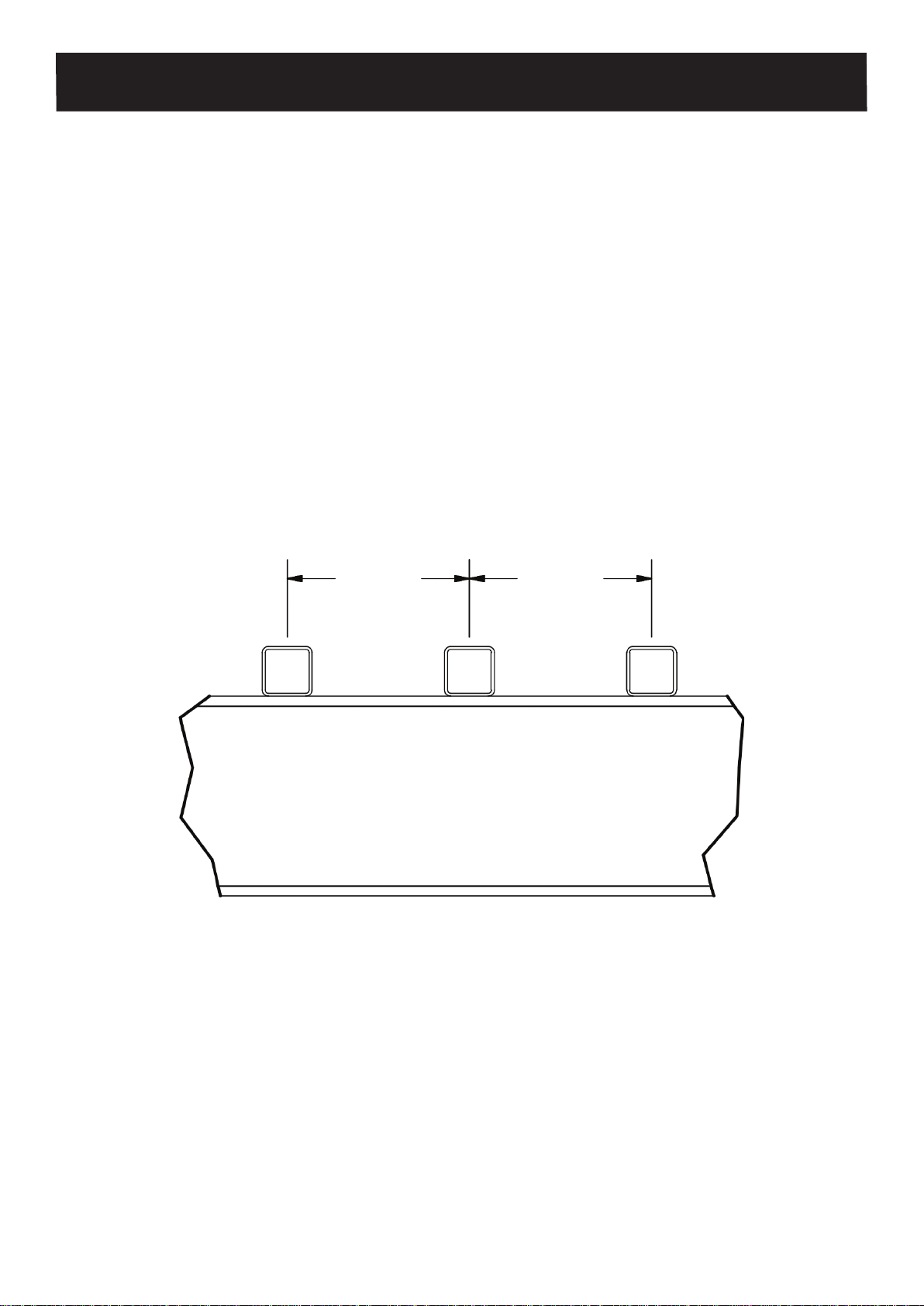

1. Adjust the container to meet these conditions:

A. The container must be straight to allow for proper parallel movement of the slats.

Determine straightness by sighting down a oor slat positioned in the container.

B. The cross-members on which the sub-deck mounts must be level, because the friction

based principle of the WALKING FLOOR® system requires a at oor. If there are

deviations exceeding 3 mm [1/8 in], make corrections.

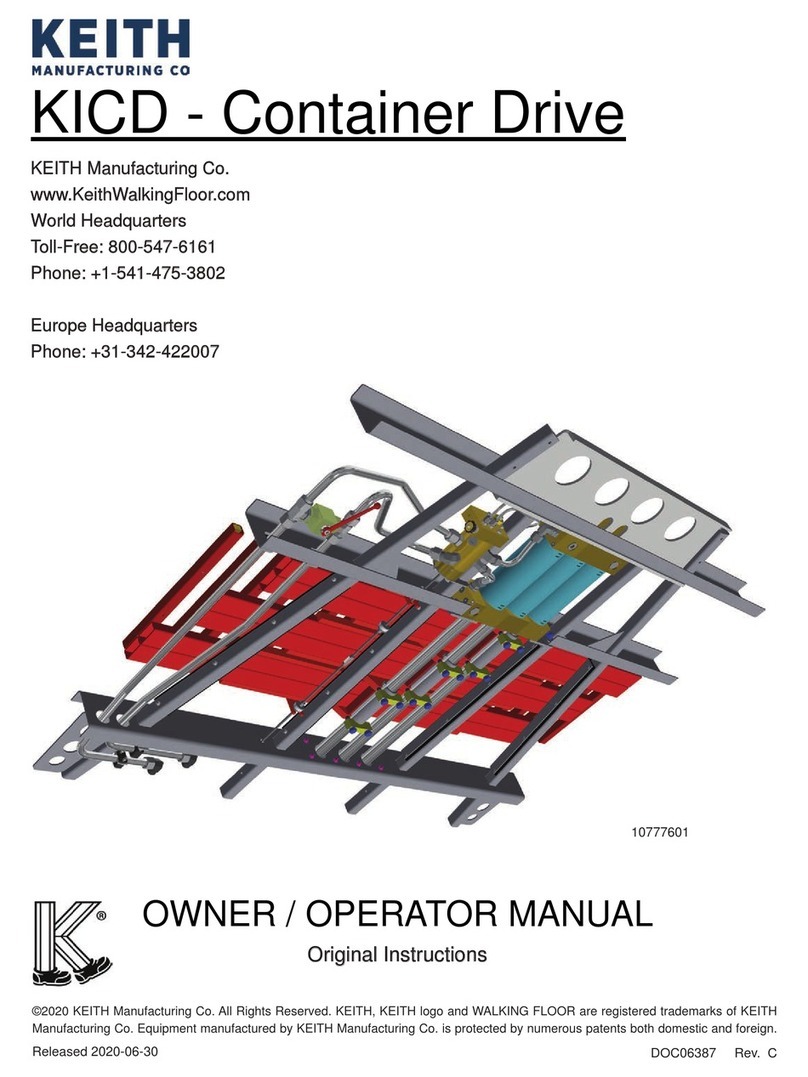

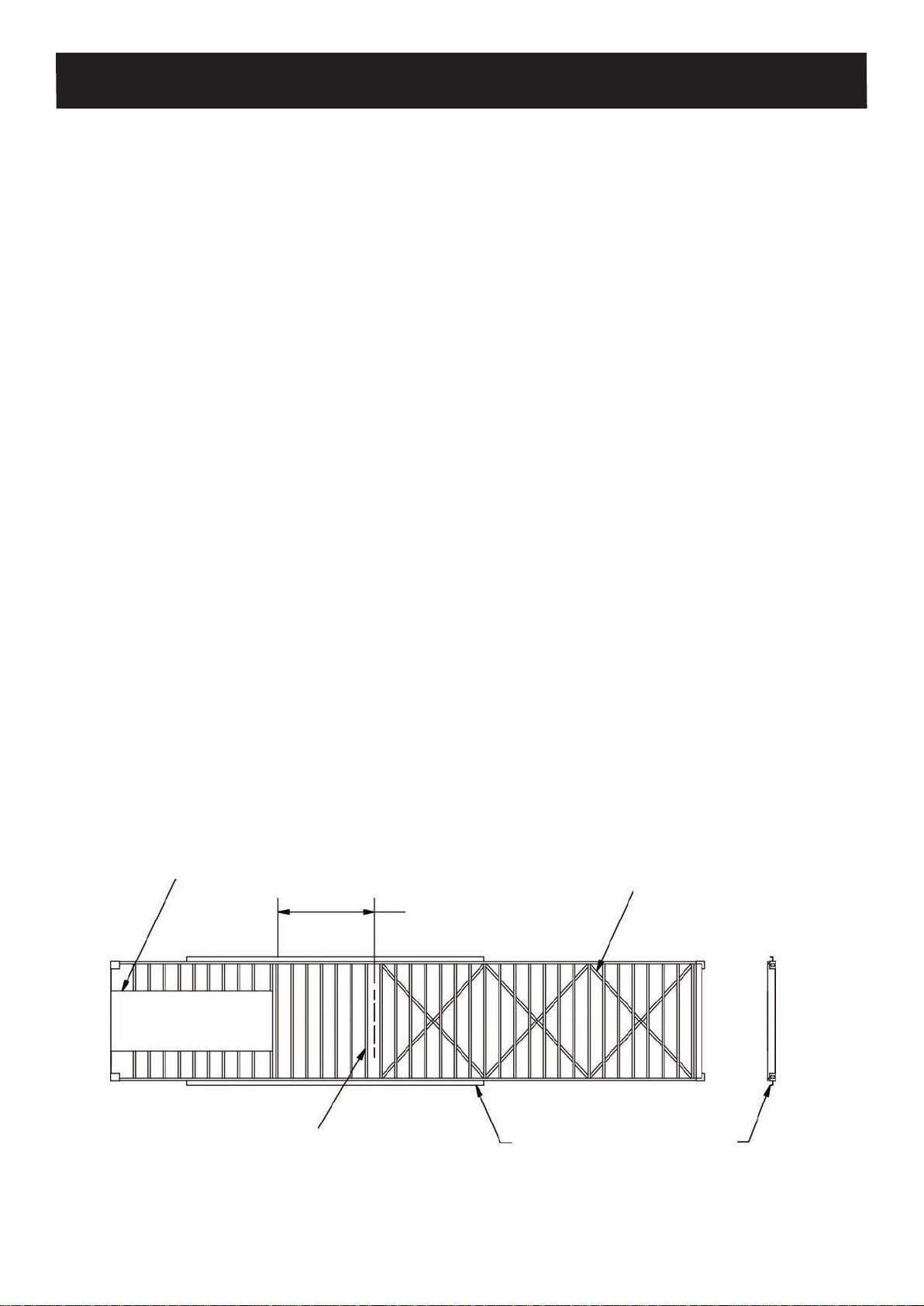

2.2 Bracing

Container bracing prevents warping.

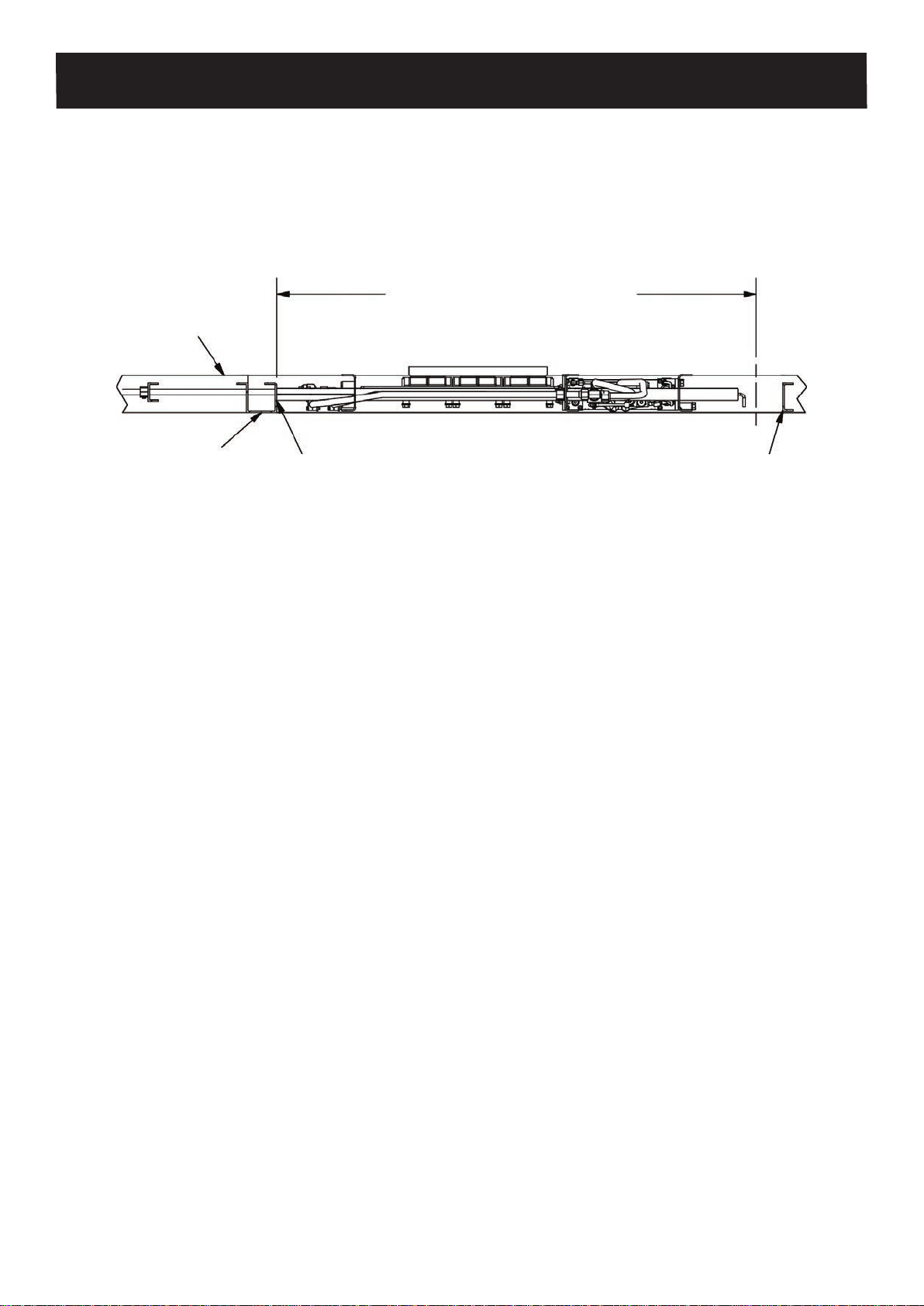

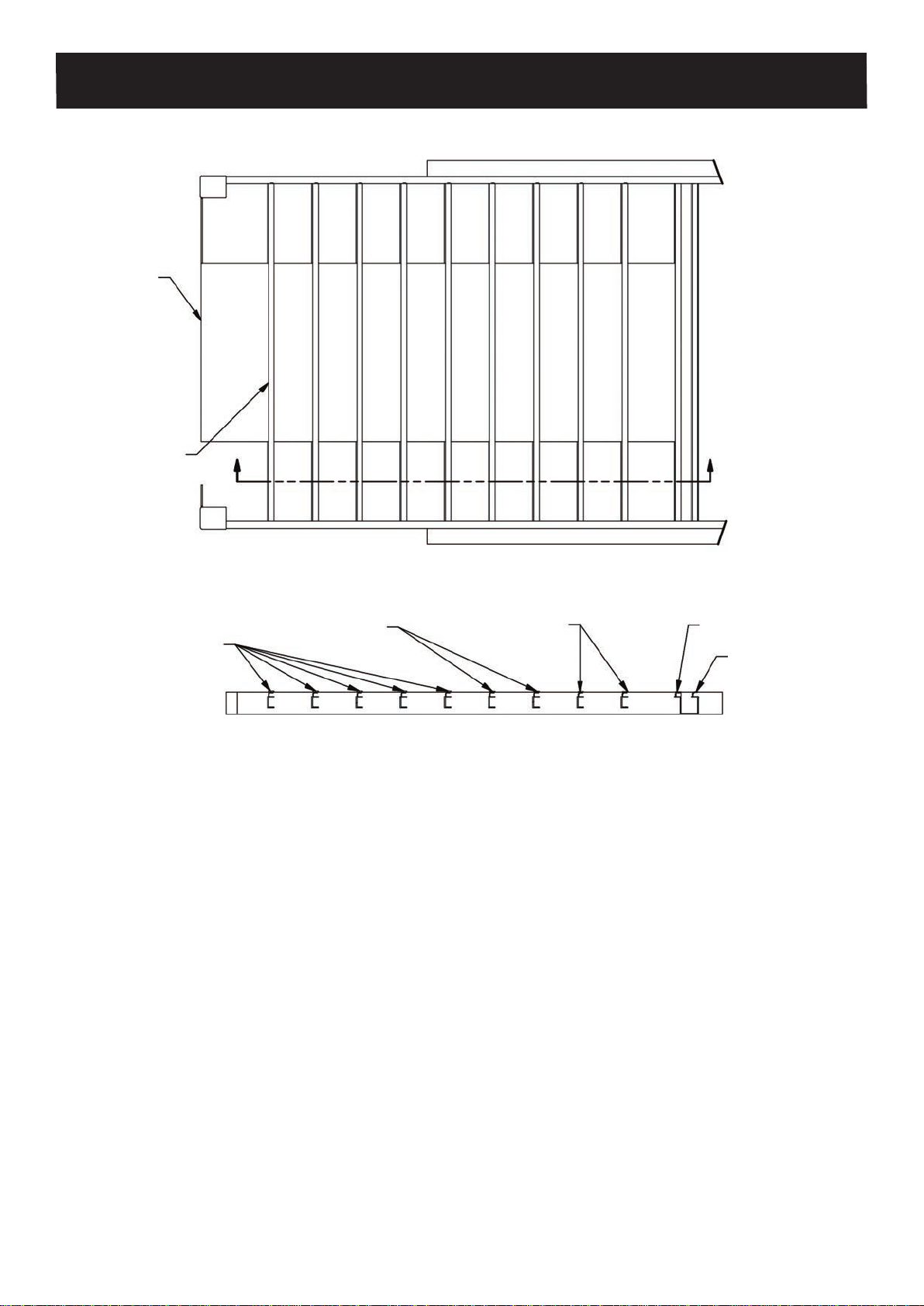

1. Install bracing as shown in Figure 1.

• It is best to add bracing before removing the old oor because the oor keeps the container

straight. If at bar is used, make a cross-bracing because it will buckle easily under

compression. The bracing reaches to the drive opening. Weld or bolt the braces to each

intersecting cross-member.

2. Weld temporary bracing onto the outside of the side rails to keep the drive opening straight. This

is very important if the top of the container was cut out rst. Remove after completion.

3. Remove old ooring.

1980 mm [78 in]

Minimum Opening

6 mm x 50 mm

[1/4 in x 2 in]

Cross-Bracing

No bracing at

drive unit opening Temporary bracing welded to

outside of container rails to

keep drive opening straight.

Remove after completion.

5th Wheel Tunnel

Figure 1