1 DOC06387 Rev. C

OWNER / OPERATOR MANUAL KICD - Container DriveOWNER / OPERATOR MANUAL KICD - Container Drive

1.0 Safety

1.1 General Safety

1.1.1 Intended Function and Expected Use:

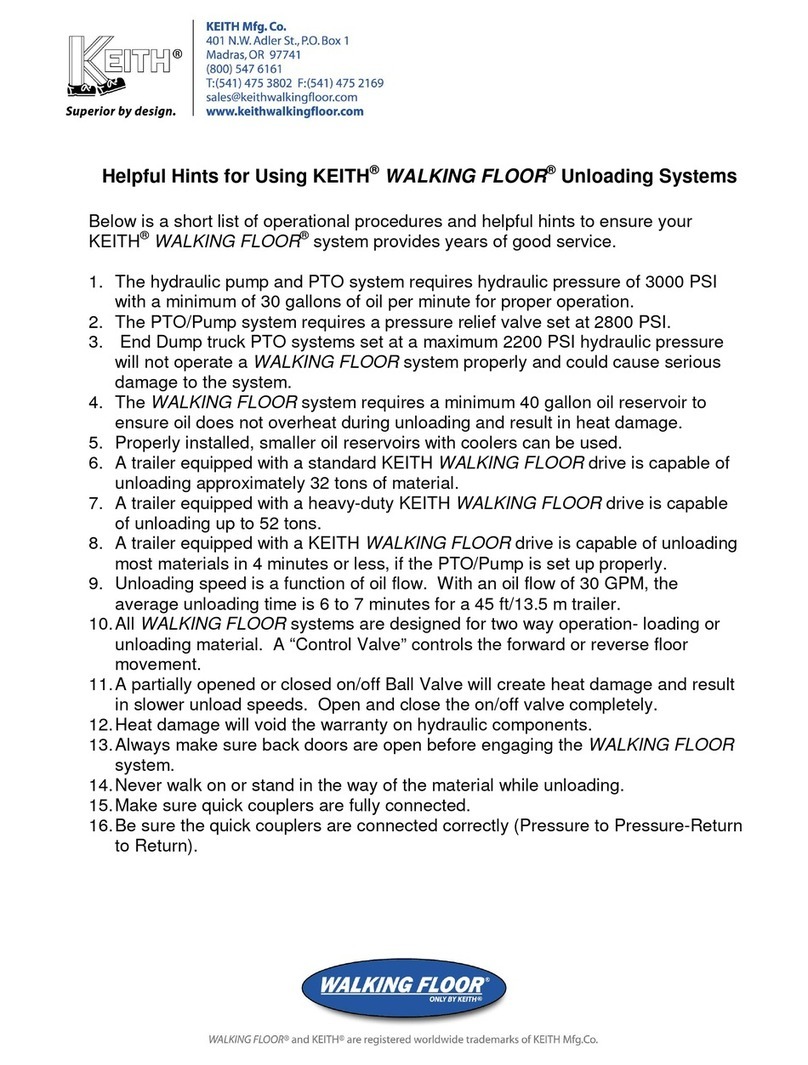

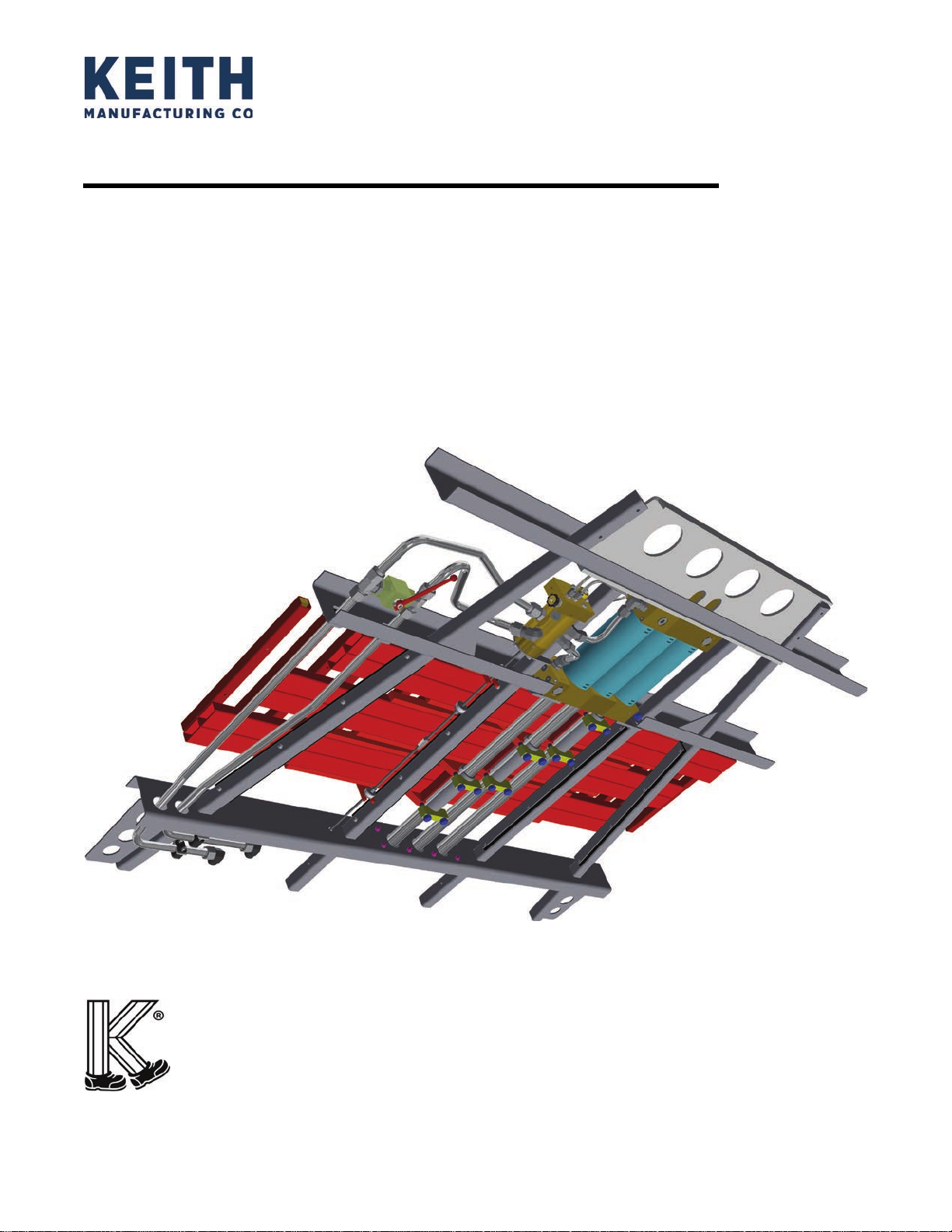

1.1.1.1. The KEITH®WALKING FLOOR®system is a reciprocating slat conveyor primarily

intended to load, hold, or unload bulk materials. It can also handle unit loads such as

pallets by using special handling techniques and possibly additional safety controls. The

system is supplied as a kit primarily intended for installation into mobile trailers or truck

bodies. The oor is often loaded through an open trailer top or through the rear doors.

The oor typically discharges material out the rear door. It is hydraulically actuated,

powered by a pump mounted either to a PTO or an electric motor. The basic system is

controlled by mechanically-actuated valves, but has the option for electrically-actuated

valves. The system is compatible with options and accessories to improve performance.

For example, it can be electrically controlled by hardwired switches or a wireless remote.

A CleenSweep®device can improve clean out. Floor slat styles are selected based on

the materials to be conveyed. The standard system handles a wide array of materials in

a non-hazardous, non-explosive environment. Special modications may be required for

special environments like food-grade applications or explosive conditions.

1.1.2 Improper Use

1.1.2.1. This equipment has been manufactured utilizing state-of-the-art technology in accordance

with acknowledged safety regulations. Nevertheless, dangerous situations could arise

from improper use, which could endanger life and limbs of personnel and cause severe

damage to the equipment and other assets. This equipment may only be used for its

intended purpose. It may only be operated in impeccable technical condition and in

accordance with the proper use and this user manual. Problems, which could aect

safety, must be resolved immediately. The manufacturer is not liable for any damage

caused by improper use or arbitrary modications. The installation, commissioning,

operation, and maintenance instructions must be followed as outlined in this manual.

1.1.2.2. Personnel must not enter the danger zone(s) when the system is enabled. Specically,

nobody should be inside, under, or behind the trailer in the unloading zone during

operation. Additionally, no one should be in a full or lling trailer. Lock-out and tag-out

procedures must be followed before accessing the drive area.

1.1.2.3. The maximum load capacity must not be exceeded. (See 2.0 Specications section)

1.1.2.4. The hydraulic power source must not exceed the pressure and ow ratings. Install a relief

valve to ensure the maximum pressure is not exceeded.

1.1.2.5. Control circuitry must not be altered or bypassed.

1.1.2.6. Safeguards must not be altered or bypassed.

1.1.2.7. The oor structure must not be altered.

1.1.2.8. The oor should not be used to handle any material other than specied.

1.1.2.9. The user and system designer must understand the characteristics and safe handling

requirements of the material that is being conveyed.

1.1.2.10. Bulk materials are by nature unstable and owable. Avoid burial by avoiding contact with

the material.

1.1.3 Training

1.1.3.1. Operators must read and understand this manual before operating or maintaining the

machine. Only qualied, trained personnel may execute commissioning, operation, and

maintenance of the system.