1、Packing List...................................................................................................................................... 1

2. Precautions..................................................................................................................................... 2

3、Technical Specification............................................................................................................. 3

4、Printer Overview........................................................................................................................... 4

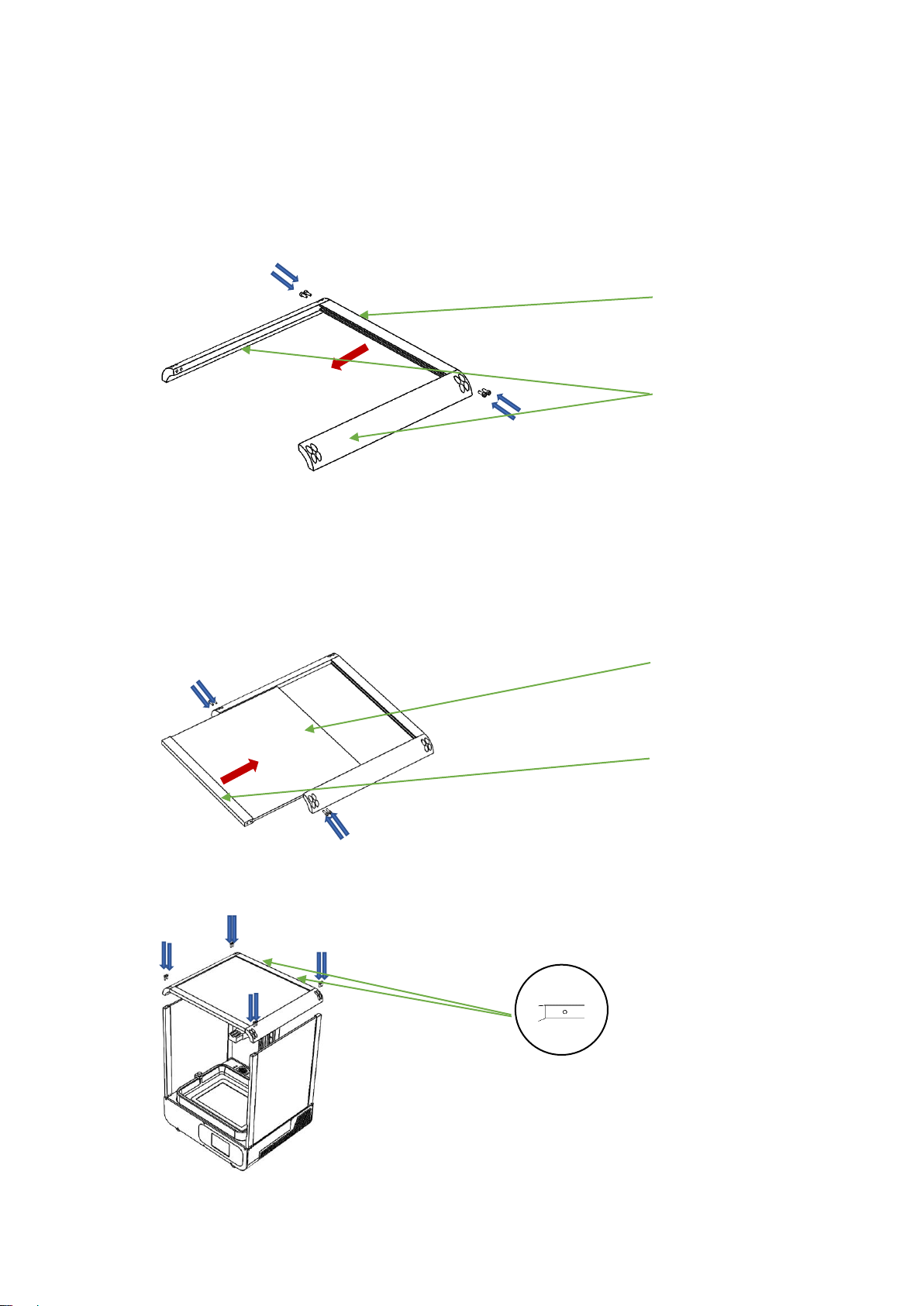

5、Assembling....................................................................................................................................... 5

6、Touch screen Introduction..................................................................................................... 9

7、Menu directory.............................................................................................................................. 9

8、Leveling ............................................................................................................................................11

9、Slice software description ....................................................................................................14

10、First print instructions..........................................................................................................22

11、FAQ and machine maintenance..................................................................................... 24