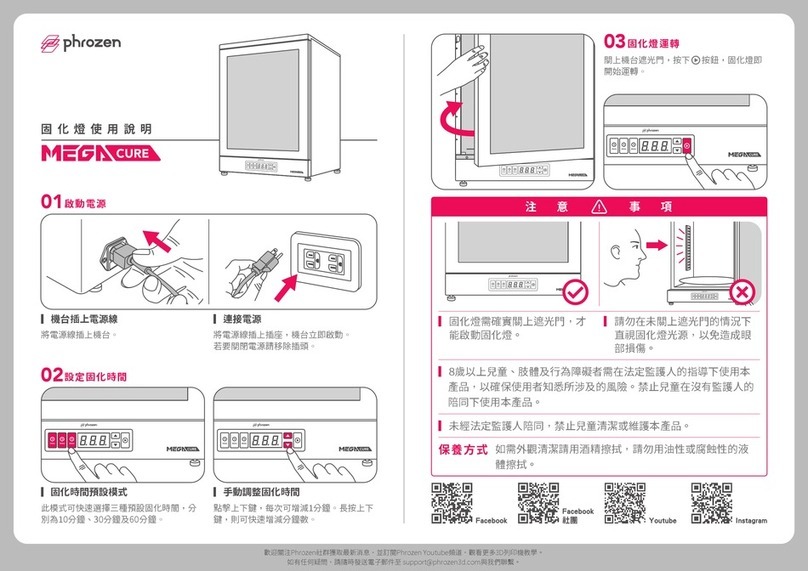

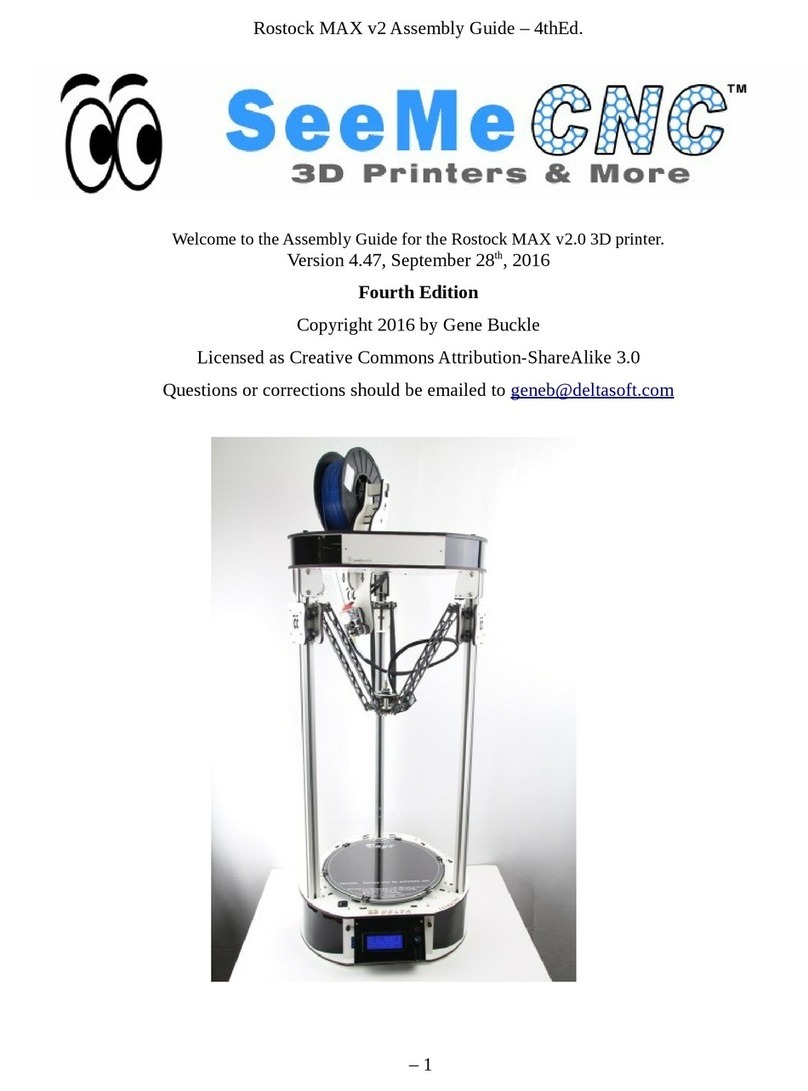

SeeMeCNC Rostock Max User manual

Rostock Max Assembly Guide

1

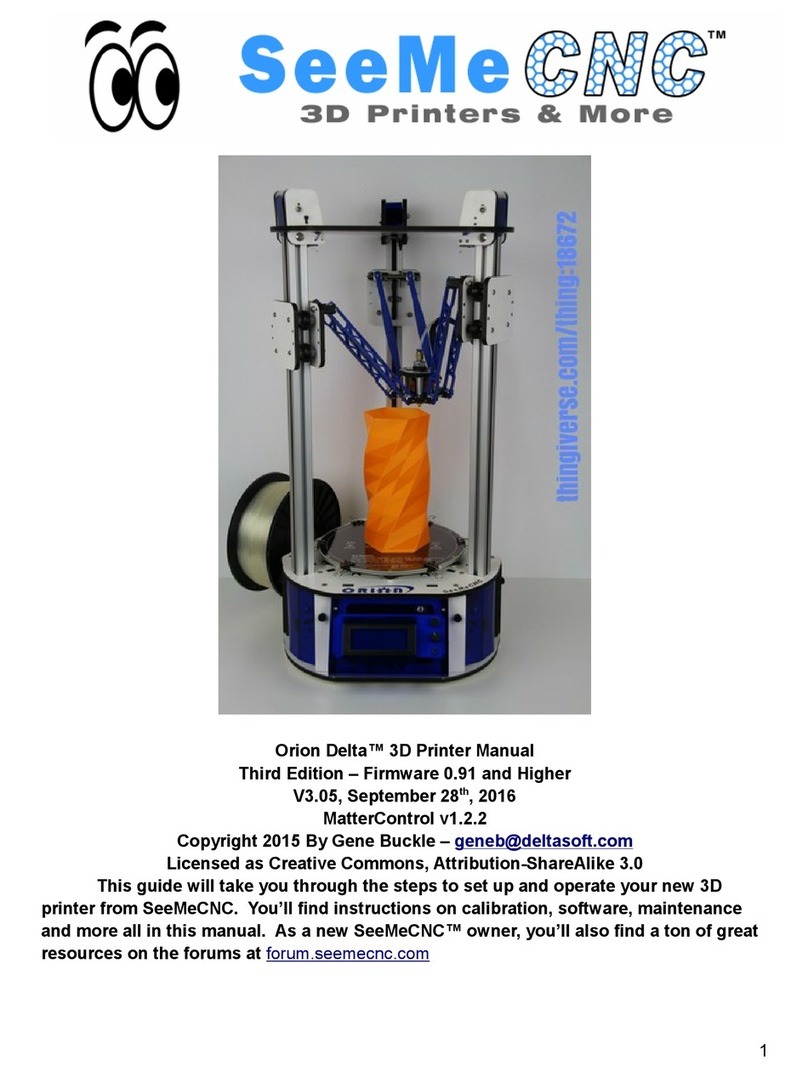

Welcome to the assembly guide for the Rostock Max 3D printer.

Before you begin, please make sure you’ve got the following tools and materials:

P1 & P2 Sized Phillips Screwdrivers

Standard Flat Head Screwdriver

3/32” Allen (hex) Wrench

5/32” Allen (hex) Wrench

Needle nose pliers

Forceps –these are VERY handy and will make your life easier in a number of the assembly

steps. They look like this:

You can purchase these online from Amazon for as little as $3.50 for a set of two.

I would recommend getting the ones with a slight curve to the jaws.

Wire Strippers

Wire Cutters

Metric Tape Measure or Meter Stick

A Small File –you may wish to get both a fine and coarse file. This is needed for adjusting

the spacing on some plastic parts later on in the build.

100-150 Grid Sand Paper

Rostock Max Assembly Guide

2

5/16” Wrench (used on the Cheapskate Bearings)

X-Acto Knife or other hand-held razor blade

PermaTex Ultra Copper High Temp RTV (used on the Hot End & Heated Bed)

Kapton Tape

Aluminum Foil

Crimp-On Wire Nuts

Split Flex Tubing (for the Hot End wires)

1 T-3/4 LED (Power on indicator for the Heated Bed)

1 1k 1/4 Watt resistor (for the LED above)

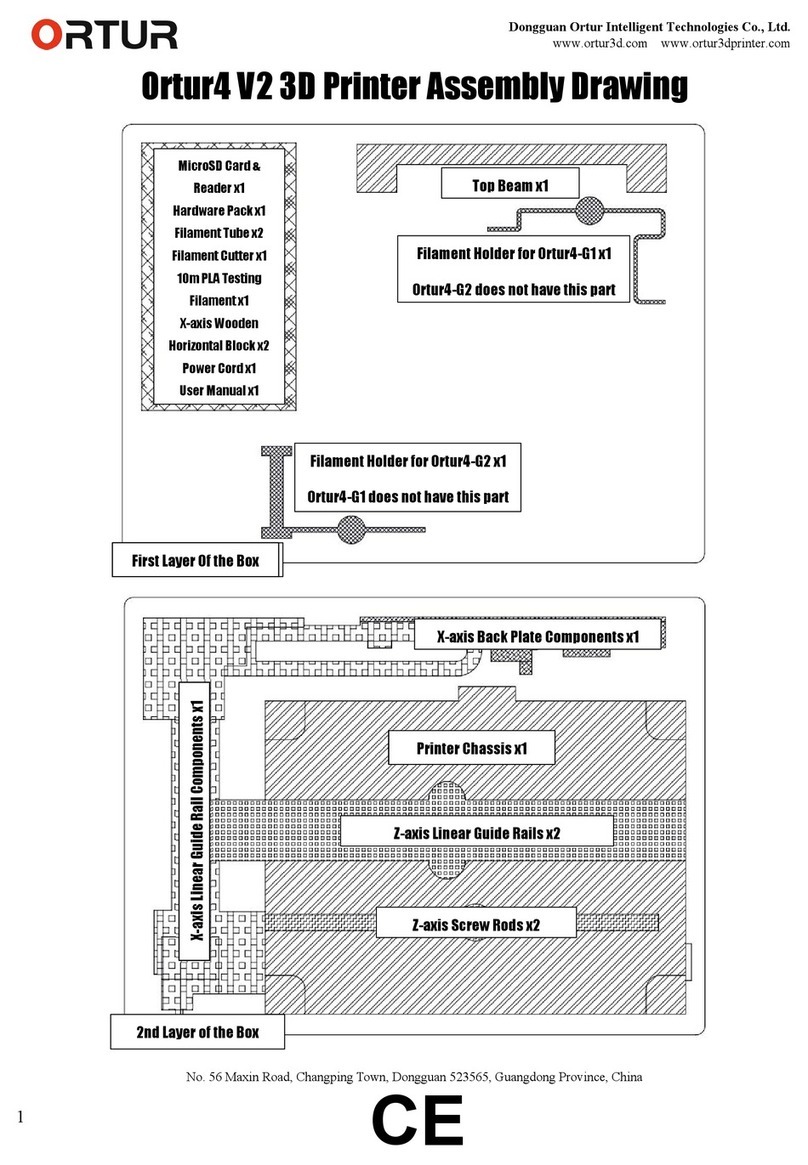

There will be a parts inventory included in the shipping box. Before you begin assembling your

Rostock Max, please check the parts included against this inventory. This will make sure you’ve got

everything you need to complete the assembly of your 3D printer. In the unlikely event that a part is

missing, contact SeeMeCNC immediately. Their technical support is excellent and you’ll have the

missing components on their way to you in no time.

The laser cut components in the Rostock Max kit are held in place with masking tape to ensure

that they’re not damaged in transit. The simplest way to remove these parts from the scrap material is

to use a razor blade to cut the tape around the perimeter of the part.

Each laser cut part also has a protective film on it that must be removed. This film prevents

“flash-over” from the laser cutting process from leaving scorch marks and combustion byproducts on

the parts. The film is removed easily –however, the film in the lettering can be difficult to remove. I

recommend using the edge of a credit card or stiff plastic scraper to remove the remaining film from

these areas.

Finally, take a dry washcloth or shop towel and wipe down the edges of each part. This will

remove most of the “soot” left over from the laser cutting process. If you’ve got an Acrylic kit, you can

of course skip this step.

Rostock Max Assembly Guide

3

Figure 1 –The parts for the Rostock MAX printer.

Rostock Max Assembly Guide

4

1 –Assembling the Machine Base

1.1 –Pop out the counter sink rings from the bottom plate (P/N: 68355)

Figure 2 –Countersink rings.

1.2 - The counter-sink rings are simply circles have been engraved through the Melamine

surface. Popping them out is easy using the point of a razor knife. It exposes the softer inner material

of the Melamine and allows flat head screws to create their own counter-sink by the pressure they apply

as they’re tightened down.

1.3 –Install the six feet to the bottom face of the base plate (P/N:69355).

Figure 3 –Plastic parts that make up the feet for the machine.

Rostock Max Assembly Guide

5

1.4 - In the photo below I’ve got the first two feet installed – note that I initially inserted the

nylon fasteners incorrectly. The nuts should be on the _other_ side. Installing them as shown in the

photo will prevent the soft rubber caps from fitting properly.

Figure 4 –First two feet mounted.

1.5 - This is what the six feet should look like when installed in their proper location:

Figure 5 –All six mounted, with rubber caps installed.

1.6 - The white caps just fit over the black plastic feet. Makes for a great non-slip assembly.

Rostock Max Assembly Guide

6

1.7 –Install the Tri-Supports (P/N: 86352), T-Slot Supports (P/N: 68377), and Motor Mount

(P/N: 68364)

Figure 6 - Tri Support and T-Slot Support

Figure 7 - Dry fitting the T-Slot and Tri-Support together.

Rostock Max Assembly Guide

7

1.8 - Dry fit the parts as shown in Fig 7 in order to get an idea how they go together. You’ll do

this for many steps in the assembly guide. Next, pop out the counter-sink rings on the Tri-Support and

install a pair of #6-32 Nylon lock nuts into the notches in the T-Slot Support as shown below.

Figure 8 - Lock nut installed in the T-Slot Support.

1.9 - Take two #6-32, 1” long flat head machine screws and attach the T-Slot Support to the Tri

Support as shown. Make sure that the counter-sink rings are facing out when you assemble the parts.

Figure 9 - Tri Support assembled.

Rostock Max Assembly Guide

8

1.10 - Install the Motor Mount on the T-Slot Support. You’ll want to insert two #6-32 Nylon lock

nuts as shown. Use a #6-32, 1” flat head machine screw to attach the Motor Mount to the T-Slot

Support. Do not tighten it down! Drive the screw in only a bit so it engages the Nylon. This will be

tightened down when the assembly is installed in the base plate.

1.11 - You may wish to install the stepper motors (Steps #4 & #5 below) and their connectors at

this point. It's easier to install the stepper motors on the X & Y axes without the doors in place. (The

connectors for the X and Y axis motors can be connected directly to the wires on the stepper motors,

but the Z axis requires a short extension to reach the electronics bay.)

Figure 10 - Motor Mount attached.

1.12 –Install Tri Support assemblies into the base plate. Before mounting in the base, install the

#6-32 nylon locknuts - doing them at this stage is much simpler than when the assembly is set in the

alignment notches in the base. Also note that the locknuts may not be the same dimension as the

notches they go into. They may be slightly over or under-sized depending on how they're measured.

The nuts will try to rotate and it makes the fit difficult. If the nut doesn't fit easily, turn it to a new set of

faces until it fits properly.

Rostock Max Assembly Guide

9

1.13 - Leave the screws a bit loose until all three assemblies are installed. Install first two as

shown:

Figure 11 - Two Supports installed.

1.14 - Install Power supply mount in third support –note that it’s a simple friction fit at this

point. It gets attached to the base when the whole assembly is installed.

Figure 12 - Power Supply Bracket in place.

Rostock Max Assembly Guide

10

1.15 - Place third assembly as shown

Figure 13 - Final Tri-Support installed in the base.

1.16 - Finally, tighten screws but leave them a little bit loose. Having the components

slightly free to move will help when you’re attaching the top to the base.

1.17 - Install Cover Brackets (P/N: 68361). The brackets that are installed to either side of

the power supply need to have threads cut in them.

Figure 14 - Cutting threads in the bracket.

1.18 - To cut the threads in the bracket, take a #10-32 socket head cap screw and carefully

thread them into the holes at the top & bottom of two brackets. This is where the Nylon thumb screws

will be installed in order to hold the plastic wrap-around cover.

Rostock Max Assembly Guide

11

1.19 - Using #6-32 Nylon lock nuts and #6-32, 1” flat head machine screws, install the

cover brackets in the base.

Figure 15 - Cover Brackets and Electronics Door installed.

1.20 –Install Electronics Mount (P/N: 68358) and Support Panel (P/N: 68357). Refer to Fig. 15

above for the location of the Electronics Panel. The door “pin” fits into the hole located next to

the X axis T-Slot mount.

1.21 - Install the Support Panel as shown –the door “pin” fits into the hole next to the Y axis T-

Slot mount.

Figure 16 - Support Door installation.

Rostock Max Assembly Guide

12

1.22 –Install the Base Top (P/N: 68351) With a razor knife, pop out all the counter-sink rings in

the Base Top. Ensure that you’ve got #6-32 Nylon lock nuts installed in the notches in the various

vertically oriented components. It’s difficult to install them all when the top is in place. Orient the top

so that the Z axis is straight across from the Electronics Panel

Figure 17 - Base Top Orientation

1.23 - It can be difficult to get all the tabs aligned with the slots in the top of the machine. I

recommend that you choose a point, get a few tabs inserted in the base slots and then loosely install a

few of the #6-32, 1” flat head screws around that location. This will allow you to work your way around

the top getting tabs locked in place without having them pop off areas you’ve already got set in place.

Rostock Max Assembly Guide

13

2 –Installation of the Heated Bed

2.1 - Identify the nine holes in the top marked with a laser engraved “1”. These holes are where

you’ll install nine #4-40 T-Nuts from below. The simplest way to seat the t-nuts is to use one of

the heated bed mounting screws and a washer to pull the t-nut into place. Place a t-nut into

one of the correct holes and thread in a #4-40 ¾” socket head cap screw with a washer on it.

Tighten it down until the tiny prongs have penetrated fully into the Melamine. If you’re building

an Acrylic version, flatten the prongs with your needle nosed pliers and tape the t-nuts in place

with a bit of scotch or other tape.

2.2 –Attach the heated bed to Mount Bed Insulator (P/N: 68335) using eight #4-4 ¾” socket

head screws. Set a small plastic spacer over each of the mounting holes that you installed a #4-

40 t-nut into. Set the heated bed & Bed Insulator in place. Make sure that the solder pads for

the heated bed are oriented towards the slot near the Z axis as shown in the below.

Figure 18 - Heated Bed Position

Rostock Max Assembly Guide

14

3 –Install Belt Pulleys on Stepper Motors

3.1 –When installing the pulley, make sure you do NOT over-tighten the screws. The belt pulley

is made from aluminum and can be stripped out easily. Tighten both screws equally.

Figure 19 - Belt Pulley Installed

3.2 - Note that if the set screws in your kit are as large as those shown in Fig. 19, you’ll need to

install the pulley after you’ve installed the stepper motor in the motor mount. The set screws won’t

clear the opening in the motor mount.

Rostock Max Assembly Guide

15

4 –Install the Connectors on the Stepper Motors

4.1 –If you’re installing the RAMBo or other controller board on the inside face of the

electronics mounting plate/door, you only need to add extension wires to the stepper motor for

the Z axis. If you’ll be installing the LCD controller, the drive electronics must be installed on the

inside of the electronics mounting plate. If the electronics are installed on the outside face of

the electronics mounting plate, you’ll need to test fit each stepper motor in order to determine

which ones will require an extension cable.

4.2 –Using the included wire, the extension wiring pattern goes like this:

Stepper Wire Extension Wire

Red----- ---------------------Red

Black------------------------Black

Green----------------------Green

Blue------------------------White

4.3 - The crimp on connector is wired in this order:

Pin 1 –Red

Pin 2 –Blue (White if using the extension)

Pin 3 –Green

Pin 4 –Black

Rostock Max Assembly Guide

16

4.4 - Pin 1 on the connector is indicated by a small triangle pointer that points to the end of the

connector. Fig. 20 below shows a 2 pin connector with this pin 1 arrow. The four pin stepper

connectors have the same style indicator.

Figure 20 - Pin #1 Indicating Arrow

Figure 21 - Stepper motor with connector installed

Rostock Max Assembly Guide

17

5 –Installing the Stepper Motors to the Motor Mounts

5.1 –The stepper motors are installed using four M3, 10mm pan head screws. I would

recommend using #4 star lock washers for extra peace of mind, but these are not included in the kit.

5.2 - Be very careful not to over-tighten the screws as you can easily strip out the holes on the

stepper motors.

5.3 - There are access holes directly across from each of the four stepper motor mounting holes

–they are there to allow you to install the screws on each motor. A longer than normal screwdriver may

help here.

5.4 - At this point you’ll want to install the belt pulley on each motor if you haven’t done so

already. Make sure that when you install the pulley, it’s positioned with the teeth aligned in the center

of the space as show in Fig. 22.

Figure 22 - Pulley correctly installed

Rostock Max Assembly Guide

18

6 –Installation of the Power Supply

6.1 –Install the power supply as shown in Fig. 23. The power supply is attached to the power

supply mount using four #6-32 ½” Nylon pan head screws. You’ll need your flat tip screwdriver for this.

Figure 23 - Power Supply Installation

6.2 - Insert the power supply with the wiring end pointing toward the center of the machine and

rotate to the left to set it into position.

6.3 - Do not tighten all four screws until you have them all started, otherwise you’ll only be able

to place three of the four. I recommend starting the two screws closest to the Tri Support that the

power supply mount mates to.

Rostock Max Assembly Guide

19

7 –Installation of the RAMBo Controller

7.1 –If you’re planning on installing the LCD control panel, you’ll want to install the RAMBo on

the inside of the electronics mounting plate.

7.2 - The installation uses four #4-40 x ¾” socket head cap screws, four #4-40 t-nuts, four #4 flat

washers and eight of the small plastic spacers.

7.3 - If you're building the Melamine version, don't fold back the prongs on the T-nuts. Instead,

take one of the mounting screws and a #4 washer and use that to set the T-nut into the mounting panel

as shown below:

Figure 24 - Installing the T-Nuts, front side

Figure 25 - Installing the T-nuts, back side

Rostock Max Assembly Guide

20

7.4 –If you’re installing on the inside of the mounting plate, orient the RAMBo such that the

stepper motor connectors are towards the bottom of the mounting plate. This allows the USB cable to

exit through the finger notch on the door.

7.5 - If you’re mounting to the outside, orient the board such that the stepper motor connectors

are close to the top of the mounting plate.

7.6 - The SeeMeCNC assembly video shows using one plastic spacer on either side of the board.

I chose to install the board with both spacers stacked behind the circuit board. Take care not to over-

tighten the screws or you could crack the circuit board.

Figure 26 - Mounting the RAMBo

Table of contents

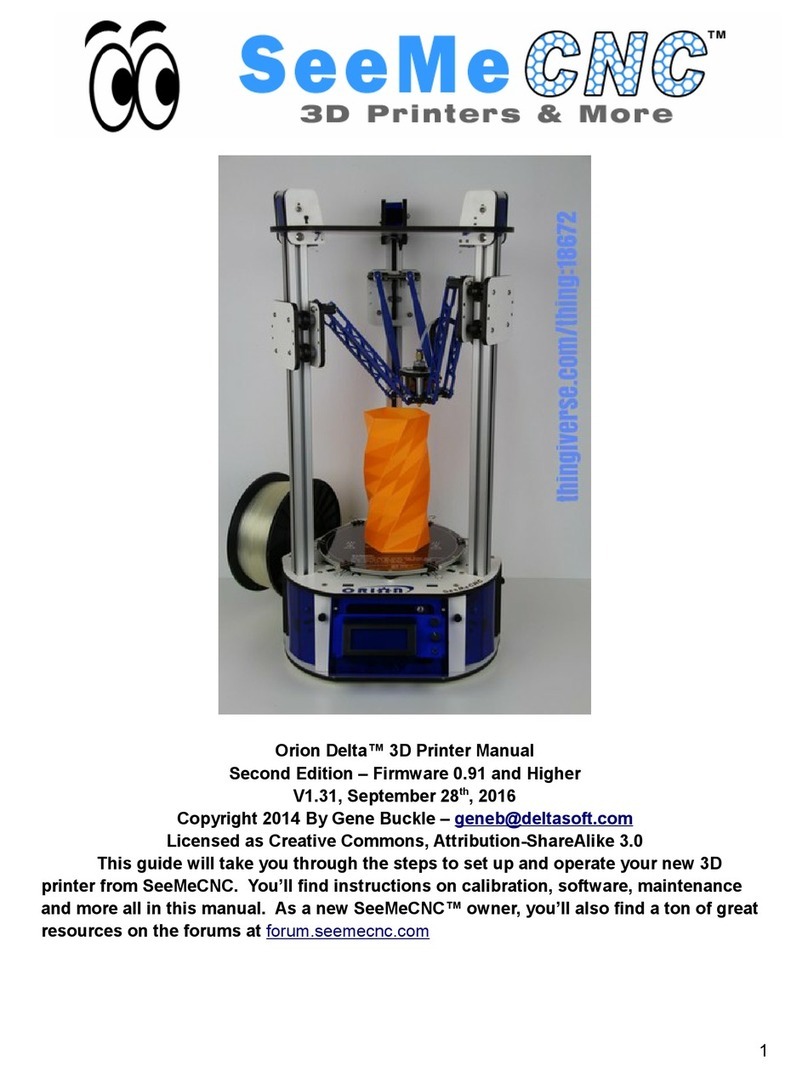

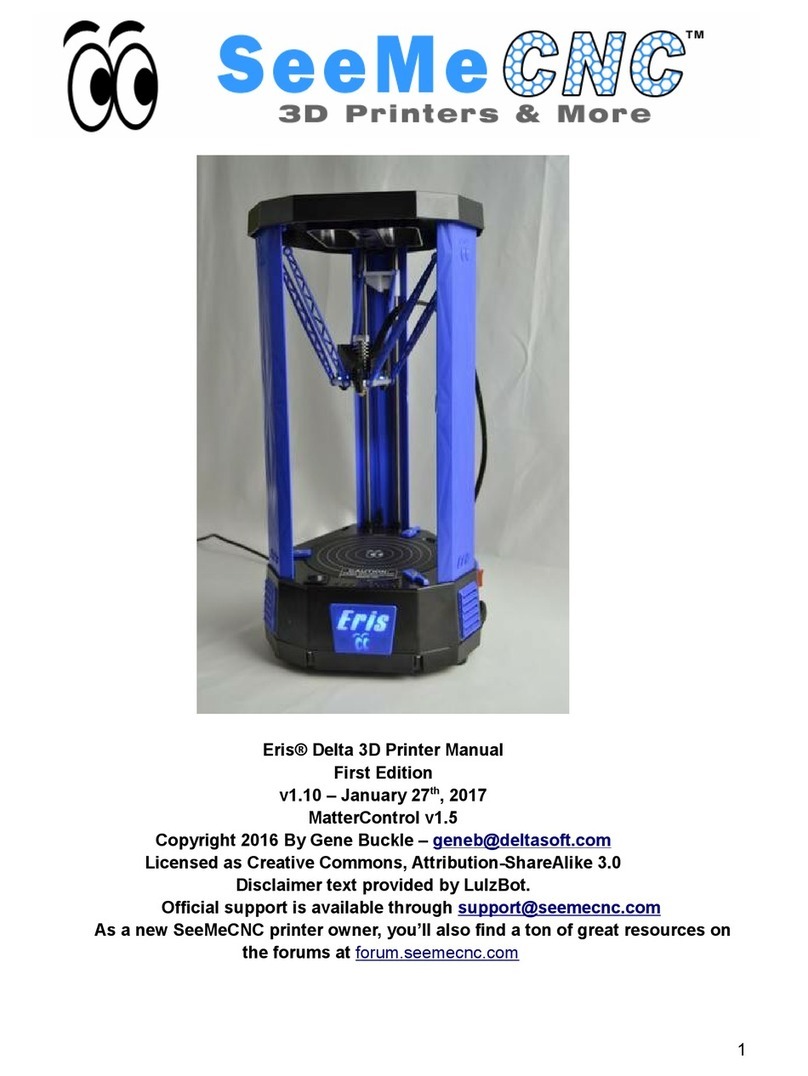

Other SeeMeCNC 3D Printer manuals

SeeMeCNC

SeeMeCNC Artemis User manual

SeeMeCNC

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

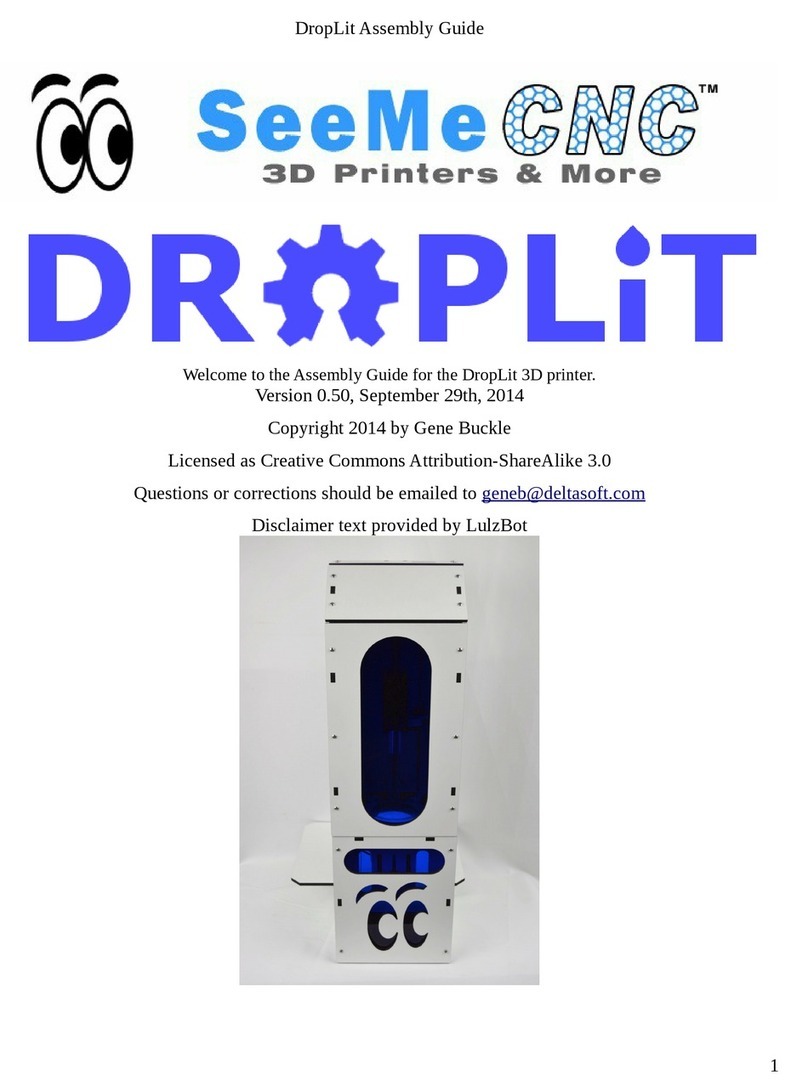

SeeMeCNC DropLit User manual

SeeMeCNC

SeeMeCNC rostock max v2.0 User manual

SeeMeCNC

SeeMeCNC Delta User manual

SeeMeCNC

SeeMeCNC Rostock Max v3 User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC orion delta User manual