Table of contents

Kellfri is not liable for any modications, changes or rebuilds carried out by customers.

SAFETY INSTRUCTIONS

Before using the equipment or product, and for the safety of yourself and others,

you must read the safetyinstructions and instruction manual and understand their contents. Always

keep the safety instructions and operating manual handy for users of the equipment or product. For

the safety of both yourself and others, it may be a good idea to read through the safety instructions

every now and then. If the safety instructions or instruction manual gets damaged or in any other

way cannot be used, new copies may be ordered from:

Kellfri AB, Munkatorpsgatan 6, SE-532 40 SKARA, Sweden.

The safety instructions can also be downloaded from Kellfri’s website: www.kellfri.co.uk

Do not use the equipment or product if you feel ill, tired or are under the inuence of alcohol.

Do not use the equipment or product if you are taking prescribed medication or drugs,

or suering from severe depression or mental illness. People under the age of 15 and those suering

from mental illness may not use the attachment.

PRODUCT SAFETY INFORMATION

• Always read the instruction manual carefully before using the backhoe digger.

• Never leave the equipment while the tractor engine is running. Turn o the engine when

you leave the equipment – even for a short period.

• Always disengage the machine before performing service or maintenance work.

• Only the operator may be present in the vicinity of the machine while in operation.

• Do not use the machine without all the guards being correctly mounted.

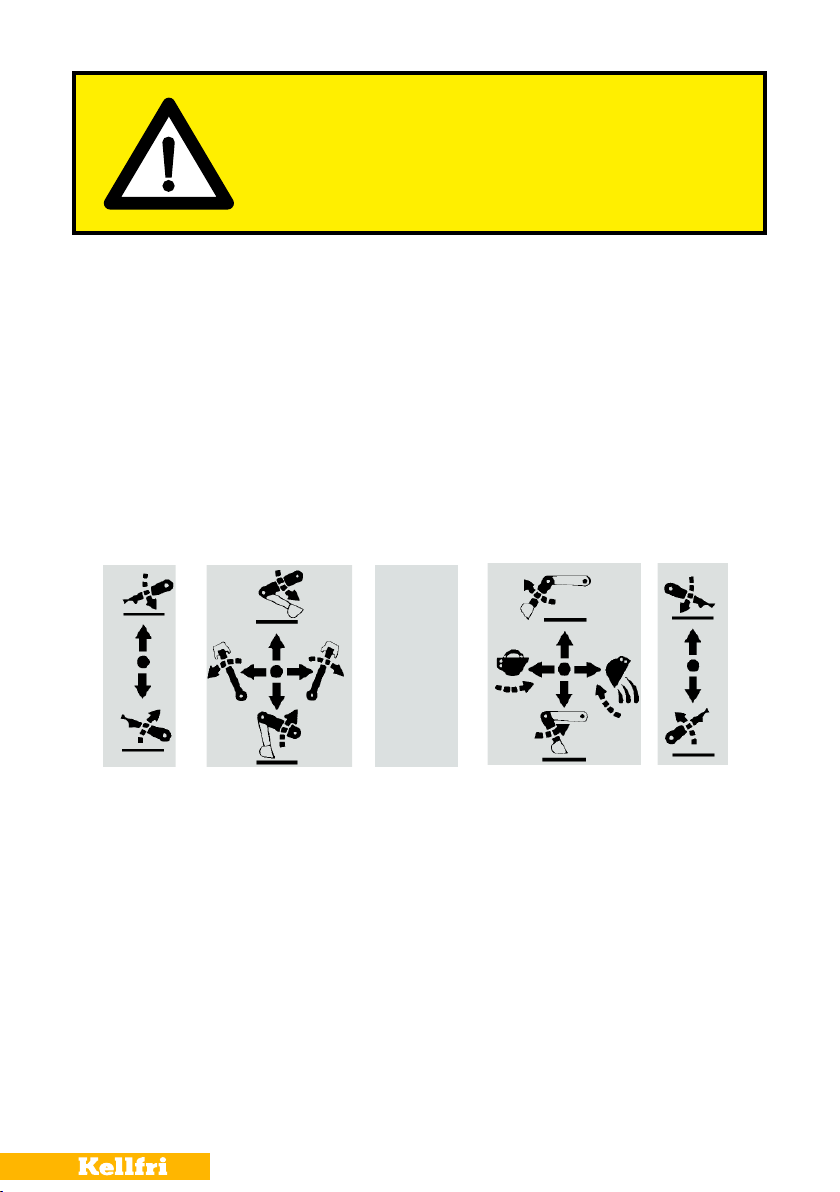

• Keep bystanders and animals away from the work area , and always make sure there is sucient

room for the attachment to swing around.

• Operate the digger from the cockpit only.

• Only use the backhoe digger for the work it is intended for. Do not use the digger to pull

objects such as barriers or lifting devices. Do not attach ropes, chains, etc. to the unit.

• Never excavate in close proximity to the stabilisers. The ground may collapse under

the backhoe digger.

• Never overload the digger’s and/or towing vehicle’s capacity.

• When working on slopes, work with the digger pointing uphill and avoid swinging the digger

sideways downhill. Avoid digging on slopes that may cause the towing vehicle to tip over.

• Reduce speed when driving on uneven terrain, on slopes or when swerving to prevent

the towing vehicle from tipping over.

• Do not adjust the valve settings. Incorrect adjustments can result in damage to the machine

and injury.

• When dismounting from the digger, lower the digger’s bucket and stabilisers to the ground.

Switch o the tractor engine, pull the handbrake and remove the ignition key.

Warning!

The original design of the machine must not, under any circumstances, be modied

without the approval of the manufacturer. Unauthorised modications and/

or accessories may cause life-threatening injuries or death to users and others.