Table of contents

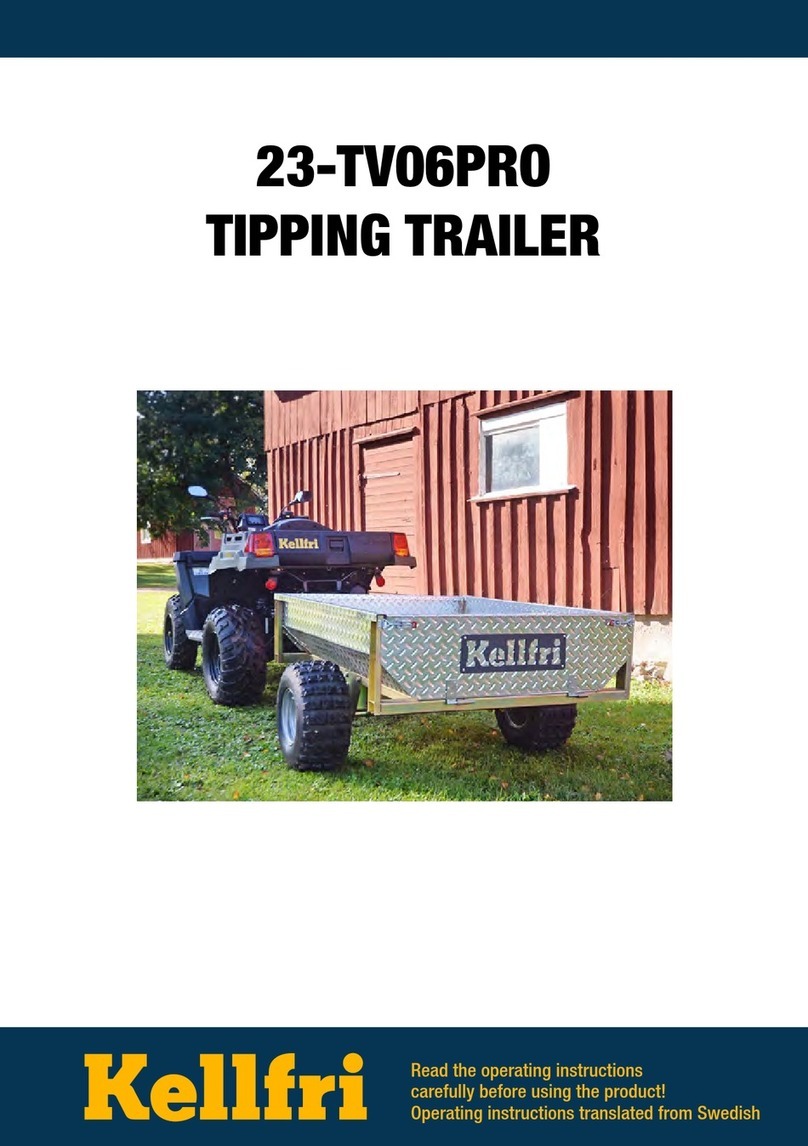

TIPPING TRAILERS

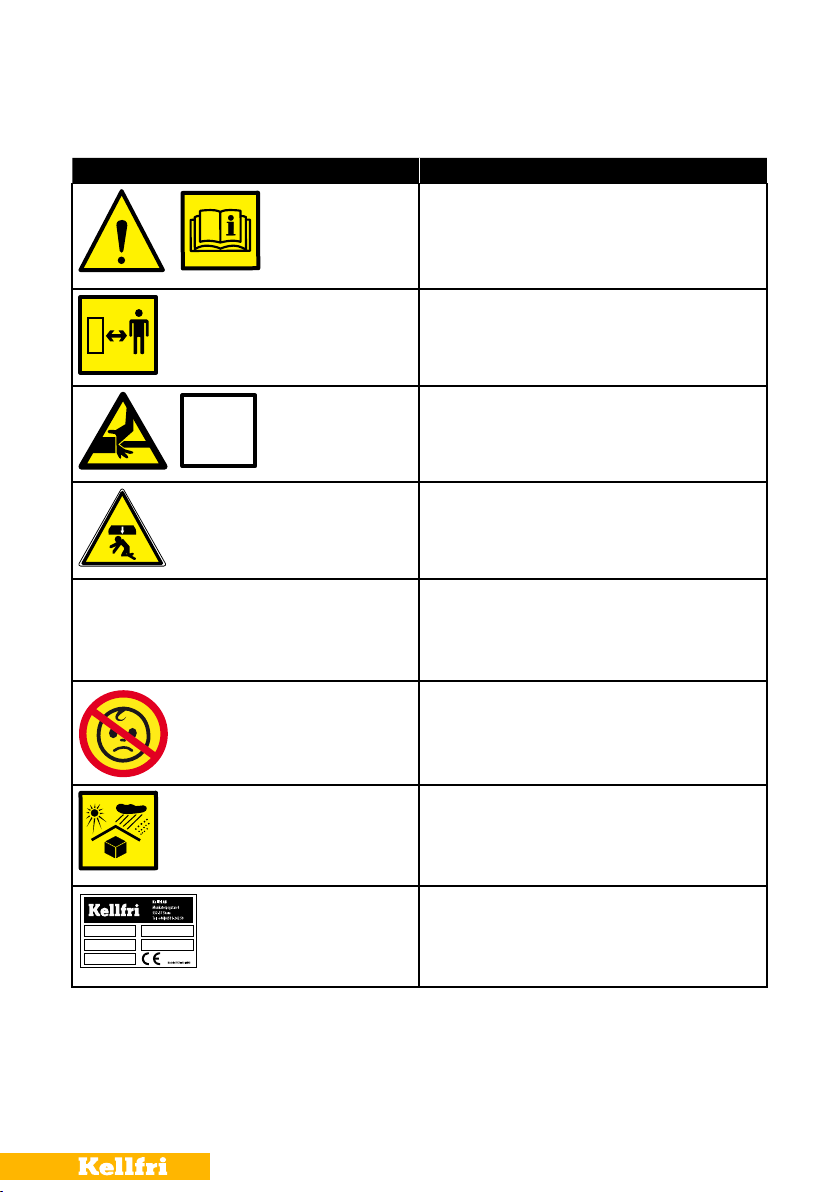

• Carefully read the trailer's operating manual before using the machine.

• Always check that the performance of the machine combination to be used with the trailer guar-

antees safety and functionality. If cracks, twists, play or fatigue are detected, discontinue use and

rectify the fault. Make sure that the towing vehicle to which the trailer is to be connected is suitable

for the purpose

• Lubricate moving parts and check that all bolts/nuts are tightened. Repair if necessary.

• Distribute the load evenly over the entire oor area. If material to be transported cannot be dis-

tributed evenly due to size or shape (e.g. large stones), bed the oor with thick planks rst. This will

reduce the load on the oor surface and protect it from damage. Always comply with applicable

regulations to ensure the permitted total weight for the vehicle is not exceeded. Protruding loads

should be well anchored.

• All operations are performed from the driver’s seat.

• Never leave the driver’s seat until the brakes on the towing vehicle have been engaged. Risk area 15

metres. Only the operator is allowed to be within the risk area while the trailer is in use.

• Only use the trailer when all necessary safety equipment is connected and secured against unin-

tended disconnection or opening (e.g. hitch and drawbar, couplings, etc.). Before starting work,

understand the equipment and all controls, as well as its functions.

• Do not leave a loaded trailer parked unsupervised. In an emergency, use the vehicle’s stopping

device to stop the movement of the equipment.

• When unhitching the trailer, it must be empty and on a level surface with the trailer wheels secured

using suitable brake blocks.

• The parking jack must always be used when carrying out maintenance and service.

• Check that the hitch between the trailer and towing vehicle is locked.When tipping, the trailer must

always be connected to the tractor. When tipping, the operator must sit in the driver’s seat in the

towing vehicle and follow the trailer’s movements carefully.

• An SMV sign must be visible and mounted when travelling on public roads. EU regulations stipulate

how fast a rig with a non-braked/braked trailer is allowed to go. Comply with these regulations.

• Operators or others should not stand under suspended loads.

• NEVER permit children or an inexperienced person to drive the trailer.

• Never allow anyone to travel on the trailer whilst it is in motion.

• Always check the trailer before use. A damaged or worn drawbar eye and/or hitch must not be

used and should be replaced before the trailer can be used. Using a damaged or worn drawbar

eye and/or hitch may cause serious damage to the trailer/equipment or death to the operator and

other persons.

• Exercise caution when working with equipment with hydraulic hoses as oil under pressure can pen-

etrate the skin. Immediately seek medical attention if this should occur.

• NOTE Do not disconnect the hydraulic hoses from the tractor, the tipper ram, couplings when the

oor is tipped.

• Never drive with the oor in the raised position. Keep an eye on the trailer, oor, aps and load when

tipping. Stop if anything unexpected should happen or if there is a risk of damage or overturning.

• Check tyre pressure - see information on the sidewalls of the tyres. Do not exceed the maximum

pressure!

• Avoid using the trailer at temperatures lower than -20°C and higher than +30°C.

• Brake regulations: If the gross weight of the trailer exceeds the gross weight of the towing vehicle,

the trailer must be equipped with a brake. For further information, contact the Transport Adminis-

tration Agency.