Page 2

LED Level Confirmation and Adjustment

The output voltage of the LED supply is factory set to be between 3.5 and 4 volts. LED intensity has a direct relationship to

the video signal voltage. The acceptable range for the peak video signal voltage (of unobstructed light through the perf

hole) is between 2.7 and 5 volts (see figure 1). Under normal circumstances, the LED power supply voltage will never need

adjustment to achieve the acceptable video voltage range. However, some combinations of individual LED intensity and

projector speed may result in a video signal out side the 2.7 and 5 volt range. in that case, it may be necessary to adjust

the LED power supply.

If the top of the video waveform is not reasonably flat (+1-1 division), check for dirt, dust, or other obstruction to the light

path, and clean as necessary.

Optical Alignment

The Reader is optically aligned at manufacture and should not require adjustment unless the CCD board has been removed

or replaced (the CCD sensor is located on the CCD circuit board, Optical alignment of the sensor depends on the positron of

the circuit board). The procedure for confirming or adjusting the position of the CCD board follows.

Lateral

Lateral position can be confirmed if the video signal (of unobstructed light through the perf hole) on the oscilloscope falls in

the center of the total CCD video signal to center the video signal on the scope do the following.

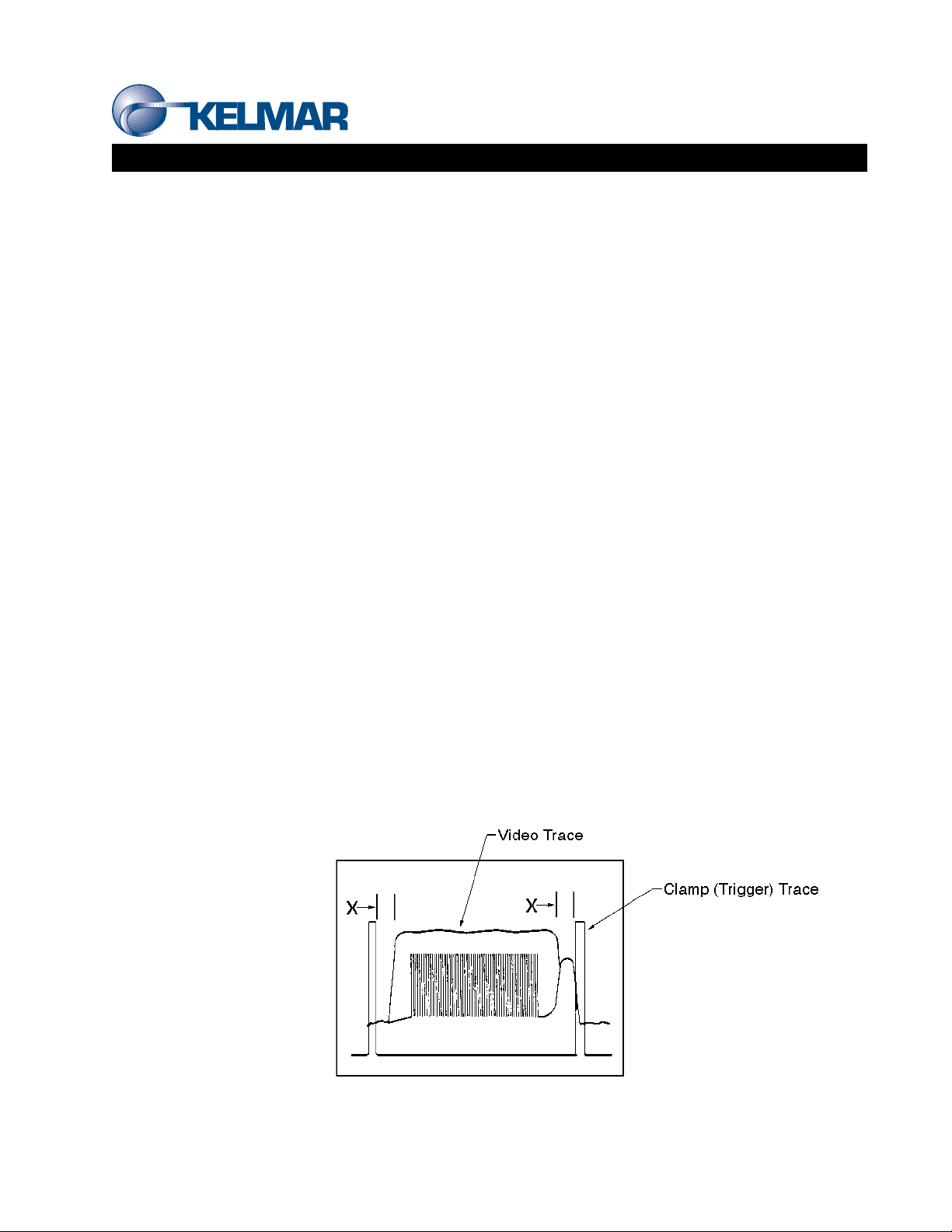

1. Use the scope setup described

in the first section of these in-

structions, observebothchannel

1 and 2.

2. Run SRD film through projector.

3. The scope image should be ad-

justed to look like the diagram

at right.

4. If theCCDcircuitboard isaligned,

the video signal of light through

the pert hole will be centered

between the falling edge of clamp (trigger trace and the rising edge of the clamp trace. As in the diagram, distance

“X’will be equal on each side of the video signal.

5. To re-align the CCD board, first loosen the lateral lock screw, and then adjust the lateral position using the lateral

adjust screw. When the video trace is centered with respect to the clamp trace, tighten the lock screw.