5

SAFETY

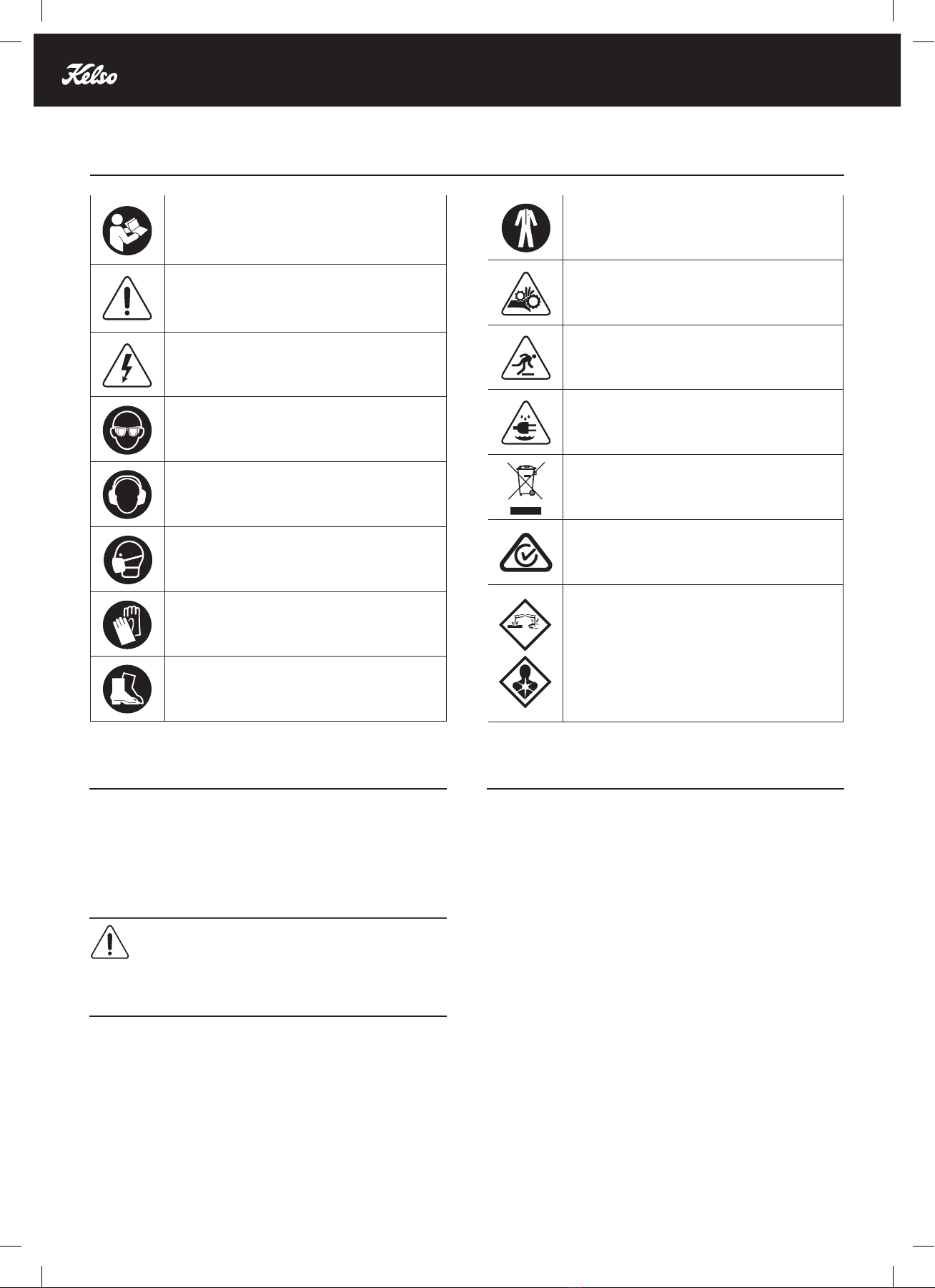

SAFETY DEFINITION

WARNING: Used if there is a risk of injury or death for the

operator or bystanders if the instructions in the manual are not

obeyed.

CAUTION: Used if there is a risk of damage to the product, other

materials or the adjacent area if the instructions in the manual

are not obeyed.

NOTE: Used to give more information that is necessary in a

given situation.

GENERAL SAFETY INSTRUCTIONS

WARNING! Read the warning instructions that follow before you

use the product.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool. This product is a dangerous tool if you are not

careful or if you use the power tool incorrectly. This power tool can

cause serious injury or death to the operator or others. Before you

use the power tool, you must read and understand the contents of

this operator’s manual.

• Save all warnings and instructions.

• Comply with all applicable laws and safety regulations in force

in your area as well as all other generally recognised rules of

safety.

• The operator and the employer of the operator must know and

control the risks during operation of the power tool.

• Do not let a person operate the power tool unless they read

and understand the contents of the operator’s manual.

• Do not operate the power tool unless you receive training

before use. Make sure that all operators receive training.

• Do not let a child (below 14 years of age) or untrained person

operate the power tool.

• This power tool is not intended for use by persons with reduced

physical, sensory or mental capabilities, unless they have

been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

• Only let approved persons operate the power tool.

• The operator is responsible for accidents that occur to other

persons or their property.

• Do not use the power tool if you are tired, ill, or under the

inuenceofalcohol,drugsormedicine.

• Always be careful and use your common sense.

• Thispowertoolproducesanelectromagneticeldduring

operation.Thiseldcanundersomecircumstancesinterfere

with active or passive medical implants. To decrease the risk of

serious injury or death, we recommend persons with medical

implants to speak to their physician and the medical implant

manufacturer before operating this power tool.

• Keep the power tool clean. Make sure that you can clearly read

signs and decals.

• Do not use the power tool if it is defective.

• Donotdomodicationstothispowertool.

• Do not operate the power tool if it is possible that other

personshavedonemodicationstothepowertool.

• Do not access the rotating parts without stopping the machine.

• Ensure power is isolated and power cord unplugged before

performing maintenance work on the machine.

• Ensure the machine is empty and power isolated during

transport of the machine.

WORK AREA SAFETY

WARNING! Read the warning instructions that follow before you

use the product.

• Make sure that only approved persons are in the work area.

• Keep children and bystanders away while operating a power

tool.

• NEVER leave the power tool running unattended. Before you

leave the work area, stop the power tool and make sure that

there is no risk of accidental start.

• Only work in a safe and stable position during operation. The

power tool should only be operated on a level ground.

• Make sure that there is no risk that you or the power tool can

fall from a height.

• Keep the work area clean and well lit.

• Keep the work area free of tripping hazards.

• Do not operate the power tool in explosive atmospheres, such

asthepresenceofammableliquids,gasesordust.

SAFETY INSTRUCTIONS FOR OPERATION

WARNING! Read the warning instructions that follow before you

use the product. Read all safety instructions before operating the

power tool.

• Beforestartingupanypowertool,youmustchecktheexible

power cable and the plug. Do not work with the power tool if

the connecting cable is damaged.

• If the connecting cable is damaged or cut during work, do not

touch it and immediately disconnect the power plug.

• The switch must be in the OFF position before you connect it to

the mains.

• The power tool shall always be supplied via residual current

device (RCD) with a rated residual current of 30mA or less.

• Do not use any adaptor plugs with earthed (grounded) power

tools.

• Do not expose the power tool to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Alwaysguidetheexiblepowercablefromthepowertoolto

therear.Neverpullhardontheexiblepowercableandnever

set it on or guide it over any sharp edges.

• Always arrange a ‘drip loop’ in the power cable below the level

of any power plugs.

• Make sure that you know how to stop the power tool quickly in

an emergency.

• Do not operate the power tool without all protective covers

installed. Keep guards in place and in working order.

• Use personal protective equipment. Refer to section ‘Personal

Protective Equipment’ in this manual.

• Make sure that there is no grease or oil on handles.