Page 3of 3

Wiring cont.

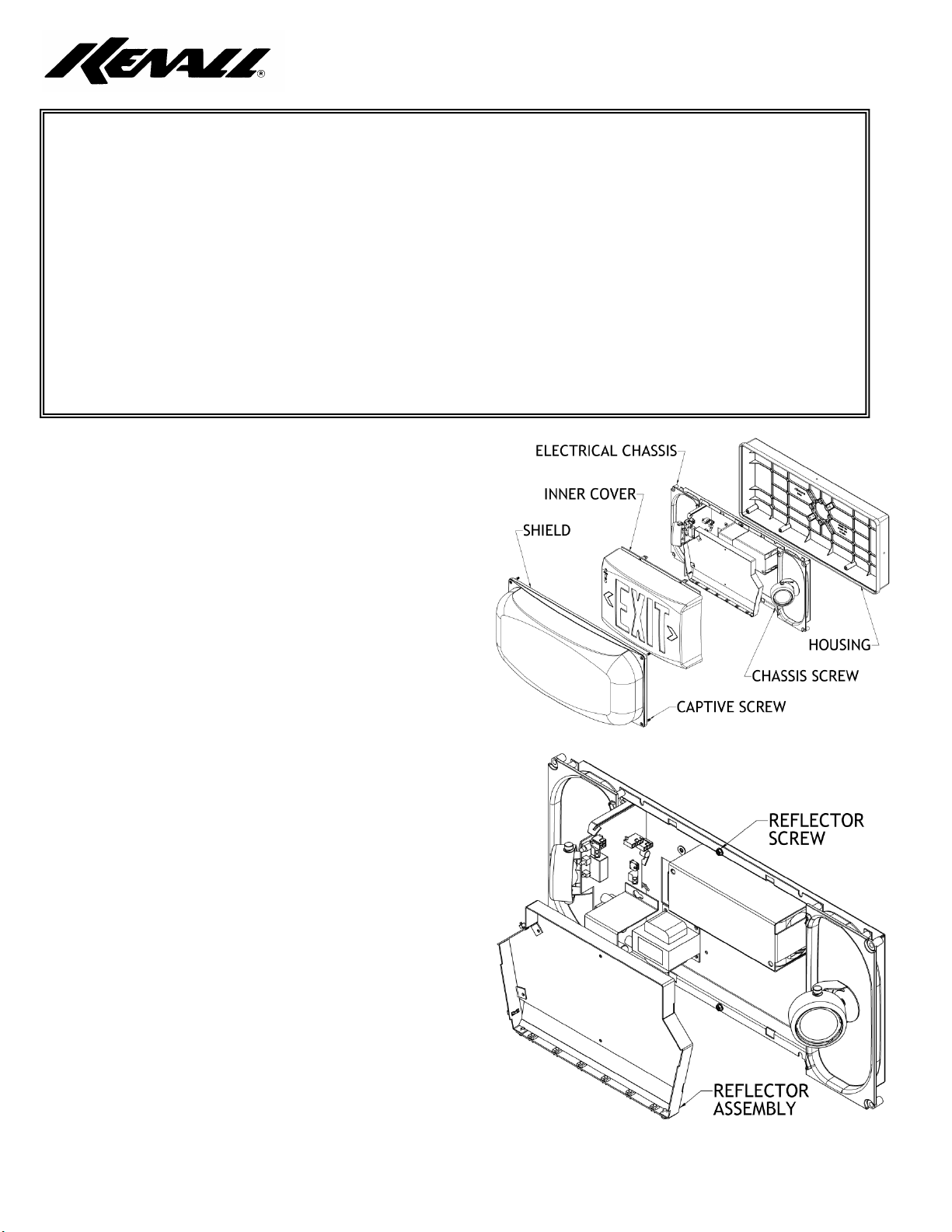

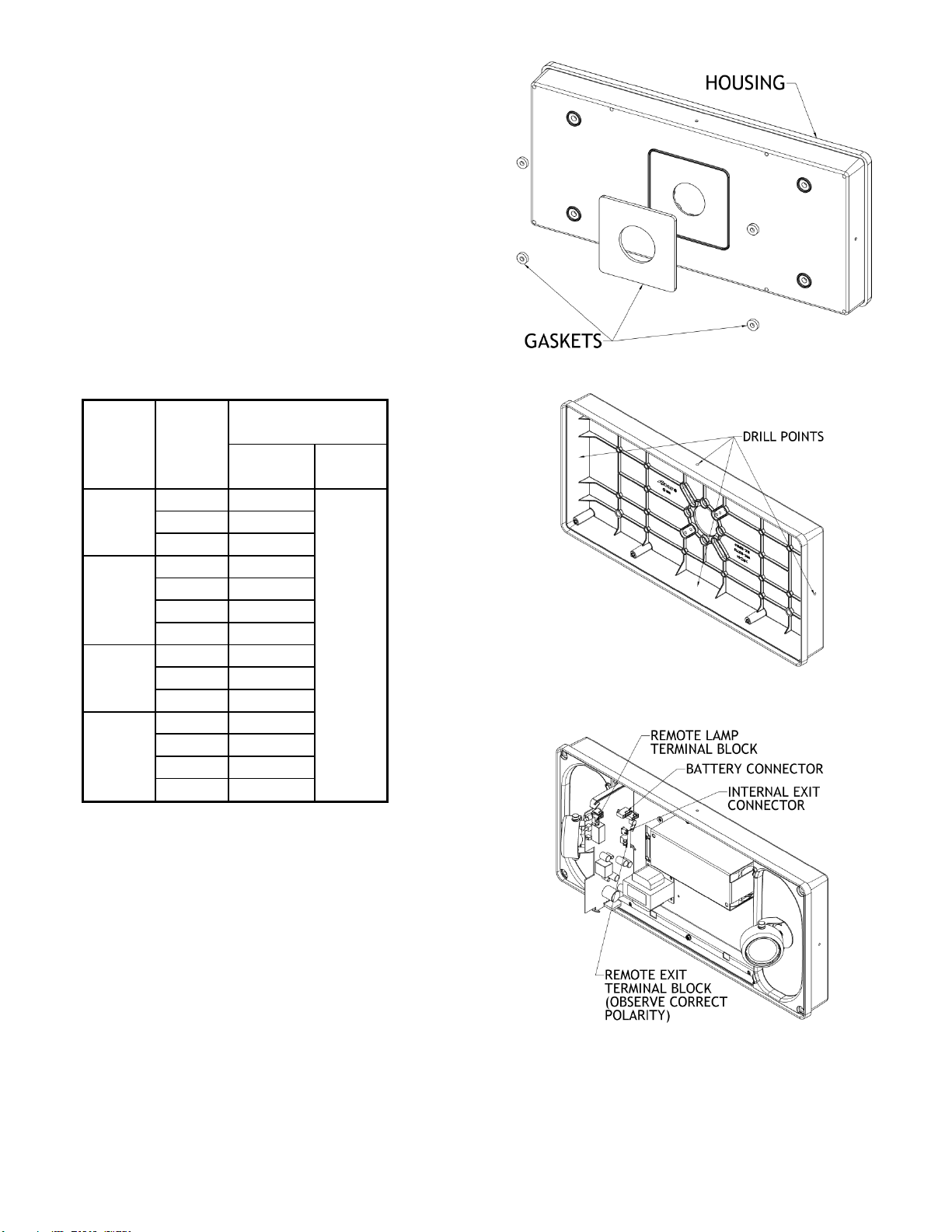

After installing ELECTRICAL CHASSIS and making field wiring

connections (AC power OFF), connect the battery to the

polarized 4-pin BATTERY CONNECTOR on the PC board

assembly. On units equipped with two batteries, BATTERY

CONNECTOR #1 should always be connected first and

disconnected last.

Upon connection of final BATTERY CONNECTOR, the

emergency lamps will illuminate for a few seconds and then

extinguish. This signals that the batteries are properly

connected and are protected from discharging until AC power

is established.

Connect exit sign power cable from REFLECTOR ASSEMBLY to

polarized INTERNAL EXIT CONNECTOR on PC board. Reattach

REFLECTOR ASSEMBLY to ELECTRICAL CHASSIS, observing

proper orientation (LED strip at bottom), and tighten

REFLECTOR SCREWs.

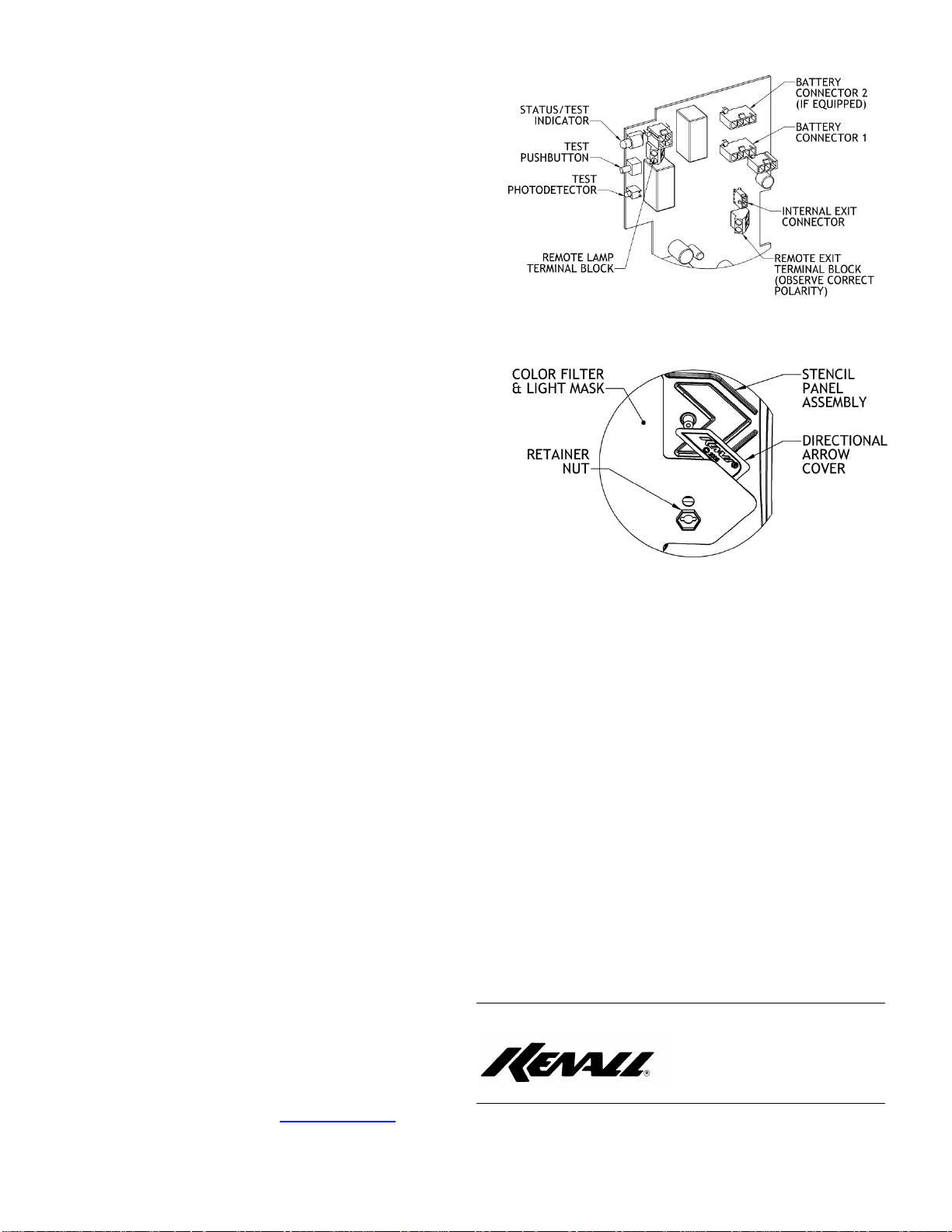

Directional Indicators (Fig. 7): Configure

DIRECTIONAL ARROWs as needed. To remove DIRECTIONAL

ARROW COVER, use 7/16” nut driver (not supplied) to loosen

RETAINER NUT approx. one complete turn. Push in cover from

outside. Tighten RETAINER NUT to secure COLOR FILTER

PANEL and aluminum LIGHT MASK (if provided). Carefully

align INNER COVER over TEST PUSHBUTTON and STATUS/TEST

INDICATOR. Snap INNER COVER to ELECTRICAL CHASSIS

assembly.

Refer to Kenall document F-2933 Metrex Egress

METEC Operation Instructions for more information.

WARRANTY

This product is warranted by Kenall to be free of

defects in workmanship and materials for a period of one year

from the date of invoice. Electrical components, including but

not limited to transformers, circuit board assemblies, LED

lamps and batteries are warranted for a period of three years

from the date of invoice. Additionally, Kenall will replace

shields, housings or mounting canopies rendered inoperable by

physical abuse any time during their product life free of

charge. A toll-free hot-line number, 1-800-331-1416 is

provided for immediate resolution of any field problems

encountered in connection with the use of Kenall’s exclusive

high abuse lighting products.

Kenall reserves the right to issue credit, repair, or

replace the defective merchandise, at its option, upon

notification and confirmation by its local representative of the

defect. Kenall also reserves the right to examine the

defective product if the defect is questionable and to deny the

warranty herein for any product altered, improperly installed,

or installed in applications for which it is not intended.

Kenall assumes no responsibility for labor or freight

costs incurred in connection with the installation, removal, or

replacement of products determined to be defective or any

other consequential or incidental damages arising from the use

of the product. Kenall’s entire liability on any claim of loss or

damage resulting from a defective product is limited to the

replacement price of the product.

The foregoing warranty is exclusive of all other

warranties and no other warranties of any kind are expressed

or implied

Kenall Manufacturing Co. www.kenall.com

4/29/09

Figure 6

Figure 7

1020 Lakeside Drive, Gurnee IL 60031 F-2932 Rev.2

1-800-4KENALL Fax: (847) 360-1781