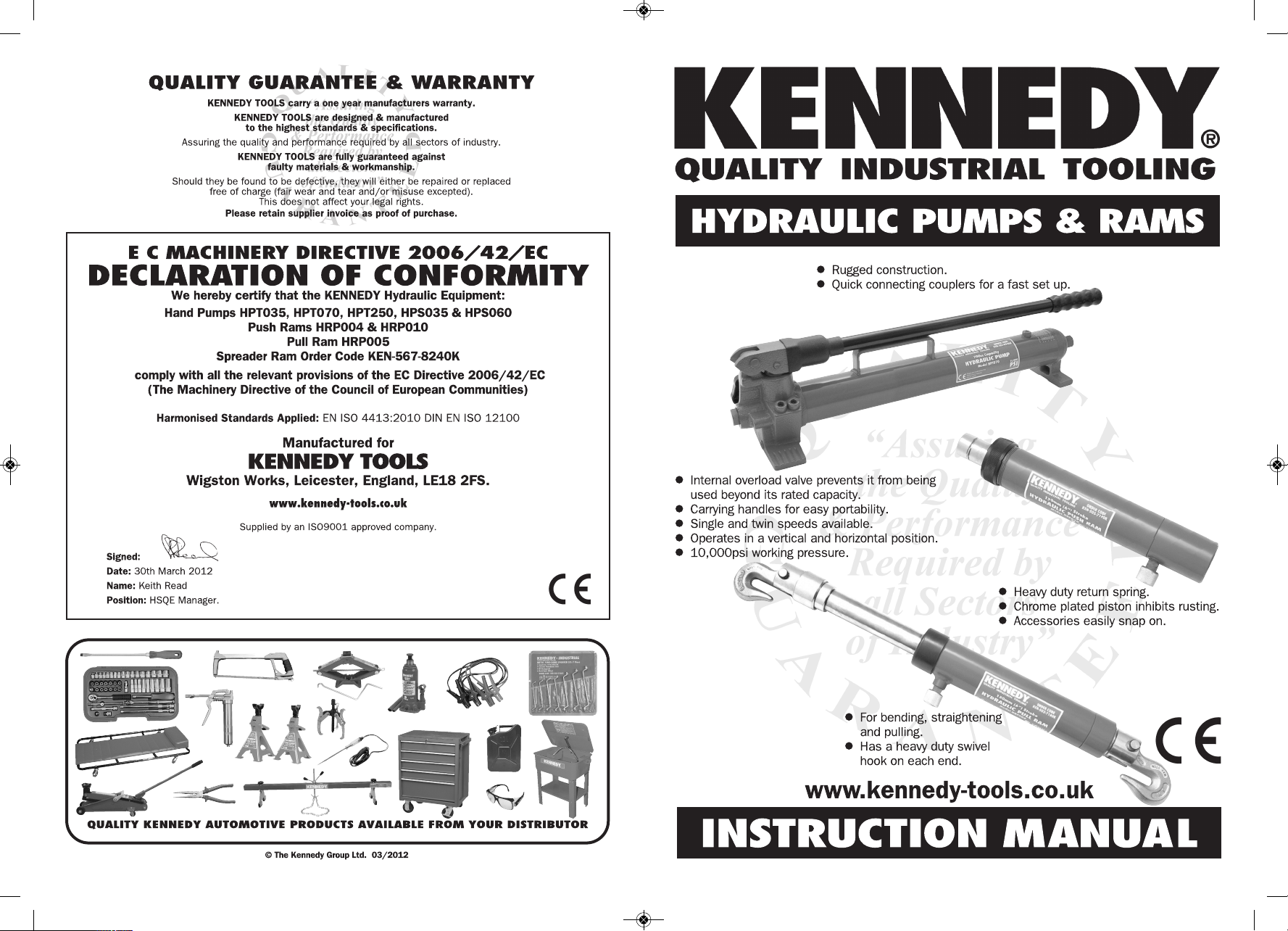

Kennedy HPS035 User manual

KEN-503-7170K_8960K_Inst uctions_KEN-503-7170K_8960K_Inst uctions.qxd 11/07/2012 13:10 Page 1

2 7

KENNEDY

thoroughly recommends reading these instructions before using

the Hydraulic Equipment even if you have used Hydraulic Equipment before.

Reading these instructions carefully and understanding them fully will enable you

to perform collision repair on a vehicle correctly and will prevent injury to yourself

or someone else as well as prevent damage to the vehicle and equipment.

SAFETY GUIDELINES

GENERAL

lAlways use approved eye and face protection. If necessary also wear protective gloves.

lAlways keep children and unauthorised people away from the work area.

lAlways store in a secure, dry place, out of reach from children.

lAlways stay alert at all times.

lAlways wear proper clothing.

lAlways inspect tools before each use.

lAlways keep tools away from heat.

lAlways ensure tools are used by qualified mechanics who are familiar with its use.

lever operate tools if any parts are missing, damaged or faulty.

lever operate tools when you are tired, under the influence of alcohol, drugs or intoxicating

medication.

lever force tools.

lever overreach.

lever stand on tools.

lever allow tools to get wet or remain in a damp environment.

HYDRAULIC EQUIPMEN

lAlways replace the dust caps back onto the couplings after use.

lAlways refill with hydraulic fluid only, making sure no dirt gets into the hydraulic system. Do

not mix different types of oil or use brake fluid.

HAND PUMPS

lAlways bleed the hand pump before use, to release any trapped air.

lAlways release the pressure from the pump when not in use.

lever modify in any way.

lever carry the pump by the hose.

PUSH & PULL RAMS

lAlways make sure the lift point is stable and properly centred on the ram.

lever exceed the the rated capacity.

lever work under loads which are supported only by hydraulic equipment. Use additional

mechanical supports.

lever use extreme heat to disassemble.

HOSES

lAlways inspect the hose each time before use.

lAlways replace hydraulic hoses within 10 years, even if no defects are detected.

lAlways ensure all hose connections are tightened and are not leaking. Do not overtighten the

hose, as this could cause premature thread failure or high pressure fittings to split at

pressures lower than their rated capacities.

lever grasp a leaking pressurised hose with your hands. The force of escaping fluid could

cause serious injury.

lever drop any heavy objects onto the hose, allow it to kink, twist, curl, crush or bend so

tightly that the fluid flow within the hose is blocked or reduced.

lever subject the hose to potential hazards such as fire, sharp surfaces, extreme heat or

cold.

lever allow the hose to come into contact with corrosive materials, such as creosote-

impregnated objects and some paints as hose deterioration can occur.

KENNEDY HYDRAULIC ACCESSORIES

150cm/5ft hose with fitted coupler. 1/

4” PT at

both ends. Suitable for single speed hand pumps. KE -567-8120K

KE -567-8140K

4 ONNE

22mm Bore Diameter 10 ONNE

33mm Bore Diameter

Spreader Plunger Toe KE -567-8360K KE -567-8500K

Spreader Ram Toe KE -567-8370K KE -567-8510K

90°“V” Base KE -567-8340K KE -567-8480K

Wedge Head KE -567-8350K KE -567-8490K

Serrated Saddle 35mm

KE -567-8390K

46mm

KE -567-8530K

Rubber Head 67mm Ø

KE -567-8380K

75mm Ø

KE -567-8520K

Flat Base 114x63mm

KE -567-8330K

150x95mm

KE -567-8470K

Double Ended Male

Snap Connector KE -567-8320K KE -567-8460K

Extension Tube 100mm (4”)

KE -567-8280K

125mm (5”)

KE -567-8420K

Extension Tube 200mm (8”)

KE -567-8290K

250mm (10”)

KE -567-8430K

Extension Tube 305mm (12”)

KE -567-8300K

355mm (14”)

KE -567-8440K

Extension Tube 410mm (16”)

KE -567-8310K

480mm (19”)

KE -567-8450K

150cm/5ft hose with fitted coupler. 3/

8” PT at pump and

1/

4” PT at ram. Suitable for twin speed hand pumps.

KEN-503-7170K_8960K_Inst uctions_KEN-503-7170K_8960K_Inst uctions.qxd 11/07/2012 13:10 Page 2

To prevent personal injury, release the pump pressure and disconnect the hose from the pump before

making any repairs. Repairs must be performed in a dirt-free environment by a qualified person who is

familiar with this type of equipment.

6 3

1. Loose couplers.

2. Restricted hydraulic line or fitting.

3. Pump not working correctly.

4. Ram seals leaking.

1. Leaky connection.

2. Ram seals leaking.

3. Pump or valve not working correctly.

1. Worn or damaged seals.

2. Loose connection.

1. Pump release valve closed.

2. Loose couplers.

3. Blocked hydraulic lines.

4. Weak or broken retraction springs.

5. The ram is damaged internally.

6. The pump reservoir is too full.

1. Tighten couplers.

2. Clean and replace if damaged.

3. Repair or replace as necessary.

4. Replace worn seals. Look for

excessive contamination or wear.

1. Clean, reseal with thread sealant

and tighten connection.

2. Replace worn seals. Look for

excessive contamination or wear.

Replace contaminated oil.

3. Repair or replace as necessary.

1. Replace worn seals. Look for

excessive contamination or wear.

Replace contaminated oil.

2. Clean, reseal with thread sealant,

and tighten connection.

1. Open the pump release valve.

2. Tighten the couplers.

3. Clean and flush the lines.

4. Send to a service centre for repair.

5. Send to a service centre for repair.

6. Drain the oil to the correct level.

Ram piston extends

slower than normal.

Ram does not hold

pressure.

Ram leaks hydraulic

oil.

Ram will not retract or

retracts slower than

normal.

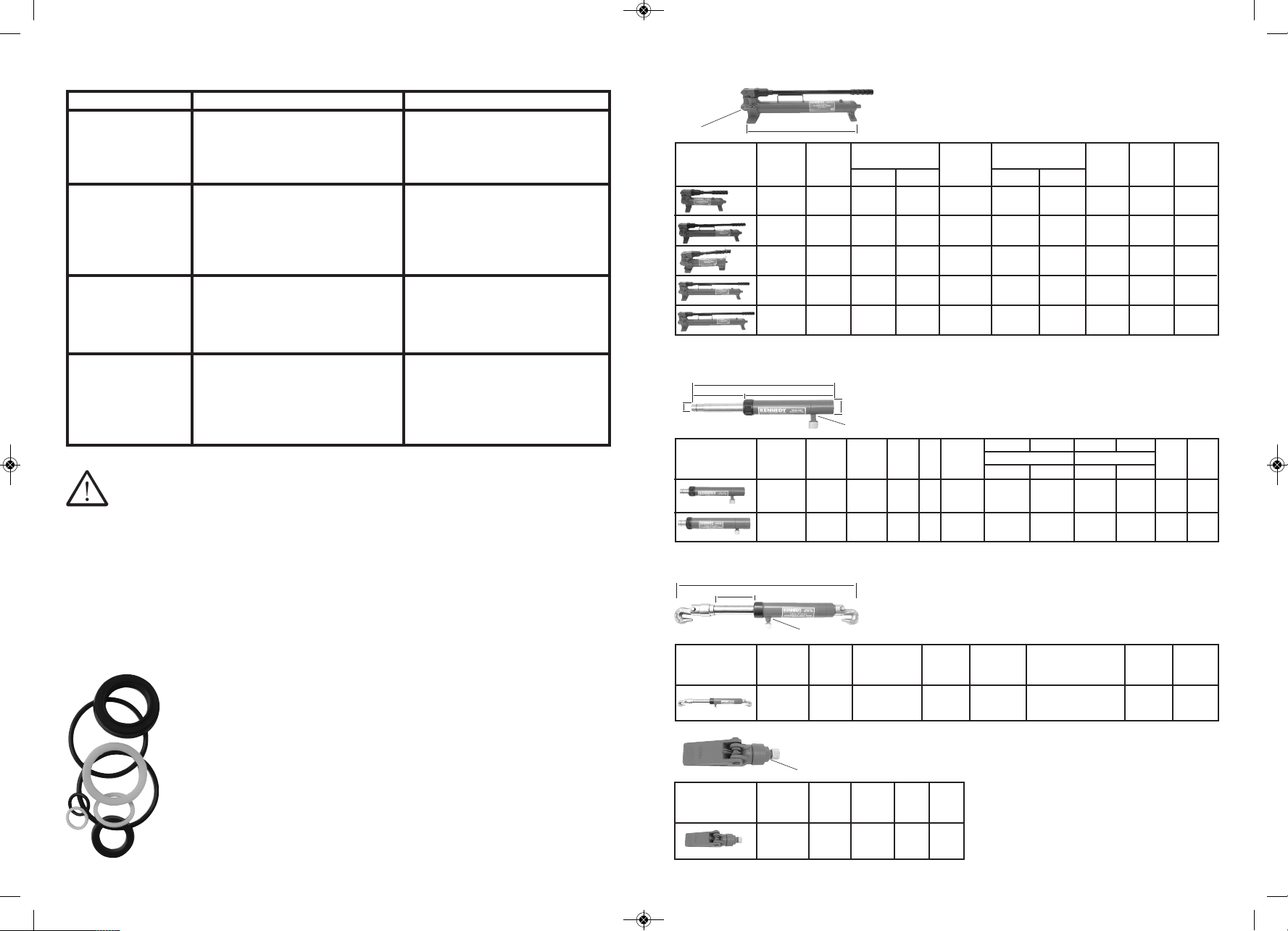

SPECIFICATIONS

Order Model Pressure rating Usable oil Oil volume per Oil port A et

code number PSI (Bar) capacity stroke (cc) thread Length weight

(KE -503) Stage 1 Stage 2 (cc) Stage 1 Stage 2 (mm) (kg)

-8800K* HPS035 10,000 - 350 3.2 - 1/

4PT 292 5.7

(700) -

-8820K** HPS060 10,000 - 600 3.2 - 1/

4PT 478 7.1

(700) -

-8900K HPT035 200 10,000 350 7.0 1.0 3/

8PT 310 5.3

(13.8) (700)

-8940K HPT070 200 10,000 700 13.0 2.8 3/

8PT 528 8

(13.8) (700)

-8960K HPT250 200 10,000 2500 13.0 2.8 3/

8PT 632 12

(13.8) (700)

Order Model Capacity A Oil Cylinder B C D E Oil et

code number (Tonne) Stroke cap Bore dia. Length (mm) Outside dia. (mm) port weight

(KE -503) (cm) (cc) (mm) Retracted Extended Piston Ram thread (kg)

-7170K* HRP004 4 10 65 28.5 230 330 22 38 1/

4PT 1.8

-7190K** HRP010 10 15 243 45 325 475 33 57 1/

4PT 5.3

Hand

pumps

Push

rams

Order Model Capacity A Cylinder B Oil et

code number (Tonne) Stroke Bore dia. Overall port weight

(KE -503) (cm) (mm) length (mm) thread (kg)

-7180K HRP005 5 15 34 740 1/

4PT 6.7

Pull

ram

Order Model Capacity Oil et

code number (Tonne) port weight

(KE -567) thread (kg)

8240K - 1/

21/

4PT 1.7

Spreader

ram

1 tonne (metric ton or t) = 1000Kg

1 ton (imperial ton) = 2240lbs (1016Kg)

PLEASE NO E The load capacity of the

hydraulic ram is affected when extension rods

are used. Please see “APPLICATIO S A D

LOAD CAPACITY” on page 4 for details.

TROUBLE SHOOTING - RAMS

Continued

REPAIRS

SPARES

POSSIBLE CAUSE SOLUTION

FAULT

Repair kits containing was ers, “O” rings and seals:

Resealing:

HAND PUMPS

KEN-503-8900K Twin s peed 350cc

capacity. (repair kit KE -567-8080K)

KEN-503-8940K Twin s peed 700cc

capacity. (repair kit KE -567-8090K)

KEN-503-8960K twin speed 2500cc

capacity. (repair kit KE -567-8100K)

KEN-503-8800K Single speed 350cc

capacity. Used with the 4 tonne Repair Kit

(KE -503-7240K). (repair kit KE -567-

8050K)

KEN-503-8820K Single speed 600cc

capacity. Used with the 10 tonne Repair

Kit (KE -503-7260K) and the 10 tonne

Bench Press (KE -985-5000K). (repair kit

KE -567-8060K)

PUSH RAMS

KEN-503-7170K 4 tonne with 100mm/4”

stroke. Used with the 4 tonne Body

Repair Kit KE -503--7240K. (repair kit

KE -567-8000K)

KEN-503-7190K 10 tonne with

150mm/6” stroke. Used with the 10

tonne Body Repair Kit KE -503-7260K.

(repair kit KE -567-8020K)

PULL RAM

KEN-503-7180K 5 tonne with 150mm/6”

stroke. (repair kit KE -567-8010K)

SPREADER RAM

KEN-567-8240K 5 tonne with 150mm/6”

stroke. (repair kit KE -567-8250K)

BENCH PRESS

KEN-985-5000K 10 tonne. (repair kit

KE -567-8250K)

Use an approved, high grade pipe thread sealant to seal all hydraulic connections. PTFE Teflon tape (KE -

983-9000K) can be used, making sure it is applied carefully (two threads back) to prevent the tape from

being pinched by the coupler and broken off inside the pipe end. Any loose pieces of tape could travel

through the system and obstruct the flow of fluid or cause the jamming of precision fitted parts.

* The same hand pump is used on the 4 tonne Kennedy Repair Kit (KE -503-7240K).

** The same hand pump is used on the Kennedy Bench Press (KE -985-5000K) and on the 10 tonne Kennedy Repair Kit

(KE -503-7260K).

* The same push ram is used on the 4 tonne Kennedy Repair Kit (KE -503-7240K).

** The same push ram is used on the 10 tonne Kennedy Repair Kit (KE -503-7260K).

DE

AB

C

A

Oil port

thread

Oil port thread

A

B

Oil port thread

Oil port thread

KEN-503-7170K_8960K_Inst uctions_KEN-503-7170K_8960K_Inst uctions.qxd 11/07/2012 13:10 Page 3

45

OPERATING

APPLICATIONS AND LOAD CAPACITY

USE:

To pressurise the hydraulic hand pump, turn the release valve on

the side of the pump clockwise to close the valve. Then pump

the handle up and down.

To release pressure, open the valve by turning the release valve

anti-clockwise.

The hand pump can be used in any position. When using the

hand pump in a vertical position, always ensure that the hose

end is facing downwards.

Adding two extension rods to

the hydraulic ram will make

the capacity reduce by 50%.

When the load is off centre the

capacity will be reduced by

a further 50% and each

additional single extension will

reduce the capacity by

a further 50%. If connecting

more than two extensions

together, ensure that the short

extension is positioned the

furthest away from the

hydraulic ram.

Pressure Release Valve

100% of ram capacity

50% of ram capacity

25% of ram capacity

6% of ram capacity

50% of ram capacity

25% of ram capacity

CARE & MAINTENANCE

CHECKING & FILLING THE OIL RESERVOIR:

1. Place the hydraulic hand pump on a level surface and disconnect any

attachment from the end.

2. Always follow the precautions advised by the oil manufacturer.

3. Open the pressure release valve.

4. Remove the filler plug from the cylinder. The oil should be within

15mm from the top of the reservoir.

If necessary, fill with hydraulic oil ISO VG.22.32 until the oil is within

15mm from the top of reservoir. DO OT USE BRAKE FLUID.

5. Pump the handle 5 or 6 times to expel air.

6. Screw on the filler plug.

Avoid mixing different grades of oil. After long periods of use, the oil should be replaced with new oil.

LUBRICATING:

Use light oil on all moving parts.

WHEN NOT IN USE:

Wipe clean with a slightly oiled cloth.

Store the hand pumps with the release valve open.

Store the rams in a vertical position with the rod end down in a dry, well protected area, where they will not be

exposed to corrosive vapours, dust or other harmful elements.

When a ram has not been used for 3 months, it should be connected to a pump and be fully extended and then

retracted to lubricate the cylinder walls, thereby reducing the potential for rust formation.

Make sure that the threaded dust cap plugs are put on to the ends of any hose, hydraulic rams and

accessories, to avoid dirt from entering the system.

BLEEDING THE SYSTEM:

Air can accumulate in the hydraulic system during the initial setup or after prolonged use, causing the ram to

respond slowly or in an unstable manner. To remove the air, please follow these steps.

1. Place the ram at a lower level than the pump, with the piston end pointing down.

2. Extend and retract the ram several times without putting a load on the system. Air will be released into the

pump reservoir.

3. With the ram fully retracted, the pump sitting level and no pressure in the hydraulic system, remove the

pump’s filler screw.

4. Pump the handle 5 or 6 times to bleed air out of the system.

5. Close the pressure release valve.

6. Replace the filler plug screw.

SETTING UP

Remove the dust covers from the hydraulic ports. Clean the area around these ports if necessary. Clean all

hose ends, couplers and union ends. Connect all hose assemblies to the pump and cylinder (sealing tape may

have to be used - See REPAIRS on page 6 for further information). Tighten securely but do not over tighten.

Filler plug

screw

Filler plug

screw positioned

here on HPT035

TROUBLE SHOOTING - PUMPS

POSSIBLE CAUSE SOLUTION

FAULT

1.System components leaking.

1. Low oil level in reservoir.

2. Seats are worn.

1. Low oil level in reservoir.

2. System components leaking.

3. Fluid leaking past inlet or outlet

check valves.

1. Air trapped in system.

2. Too much oil in reservoir.

1. Repair or replace as necessary.

1. Check oil level.

2. Repair seats or replace pump body.

1. Check oil level.

2. Repair or replace as necessary.

3. Repair inlet or outlet check valves,

or replace high pressure piston

seal.

1. Refer to ‘BLEEDI G THE SYSTEM’

on page 4.

2. Check oil level.

Pump loses pressure.

Pump not delivering oil.

Pump does not reach

rated capacity.

Pump handle has

‘spongy’ feel.

1. Loose couplers.

2. Low oil level in pump reservoir.

3. Ram seals leaking.

1. Low oil level in pump reservoir.

2. The load exceeds the capacity of the

system.

1. Tighten couplers.

2. Fill and bleed the system.

3. Replace worn seals. Look for

excessive contamination or wear.

1. Fill and bleed the system.

2. Use correct equipment.

Ram piston will not

extend.

Ram system extends

only partially.

TROUBLE SHOOTING - RAMS

POSSIBLE CAUSE SOLUTION

FAULT

Continued on page 6

INSPECTION

Before each use, please inspect the hydraulic equipment for the following:

1. A cracked or damaged cylinder.

2. Excessive wear, bending, damage or insufficient part engagement.

3. Leaking hydraulic fluid.

4. A scored or damaged piston rod.

5. Swivel heads and caps not functioning correctly.

6. Loose bolts.

7. Damaged or incorrectly assembled accessory equipment.

8. Modified, welded or altered equipment.

9. Bent or damaged couplers or port threads.

KEN-503-7170K_8960K_Inst uctions_KEN-503-7170K_8960K_Inst uctions.qxd 11/07/2012 13:10 Page 4

This manual suits for next models

7

Other Kennedy Water Pump manuals