INSTALLATION

USE AND MAINTENANCE MANUAL

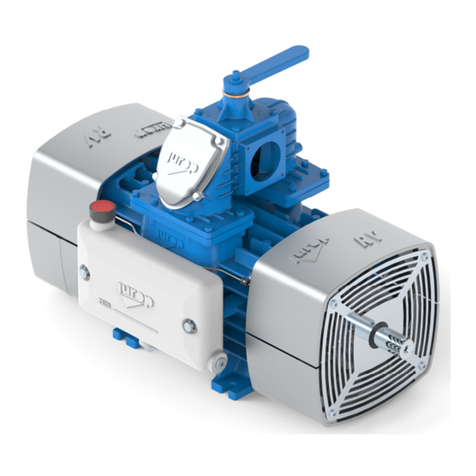

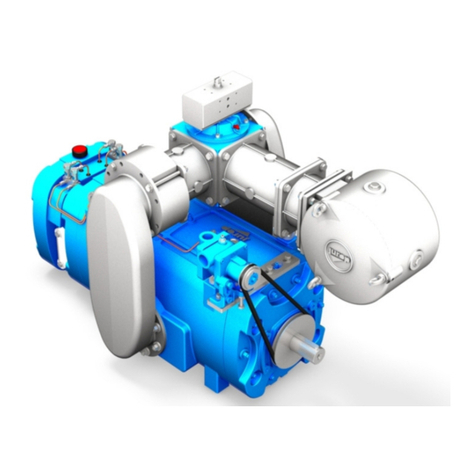

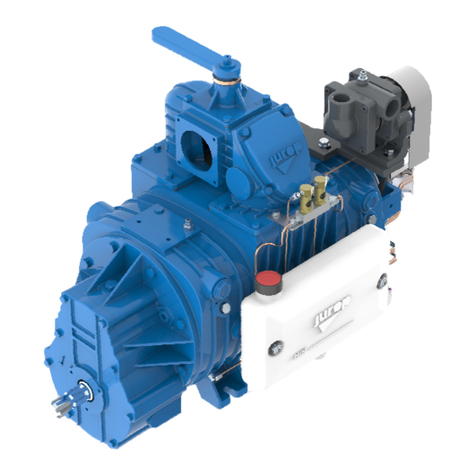

RV360-520

REV

20-10-2021

8 / 32

Jurop SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

EL

AX

http://www.jurop.it

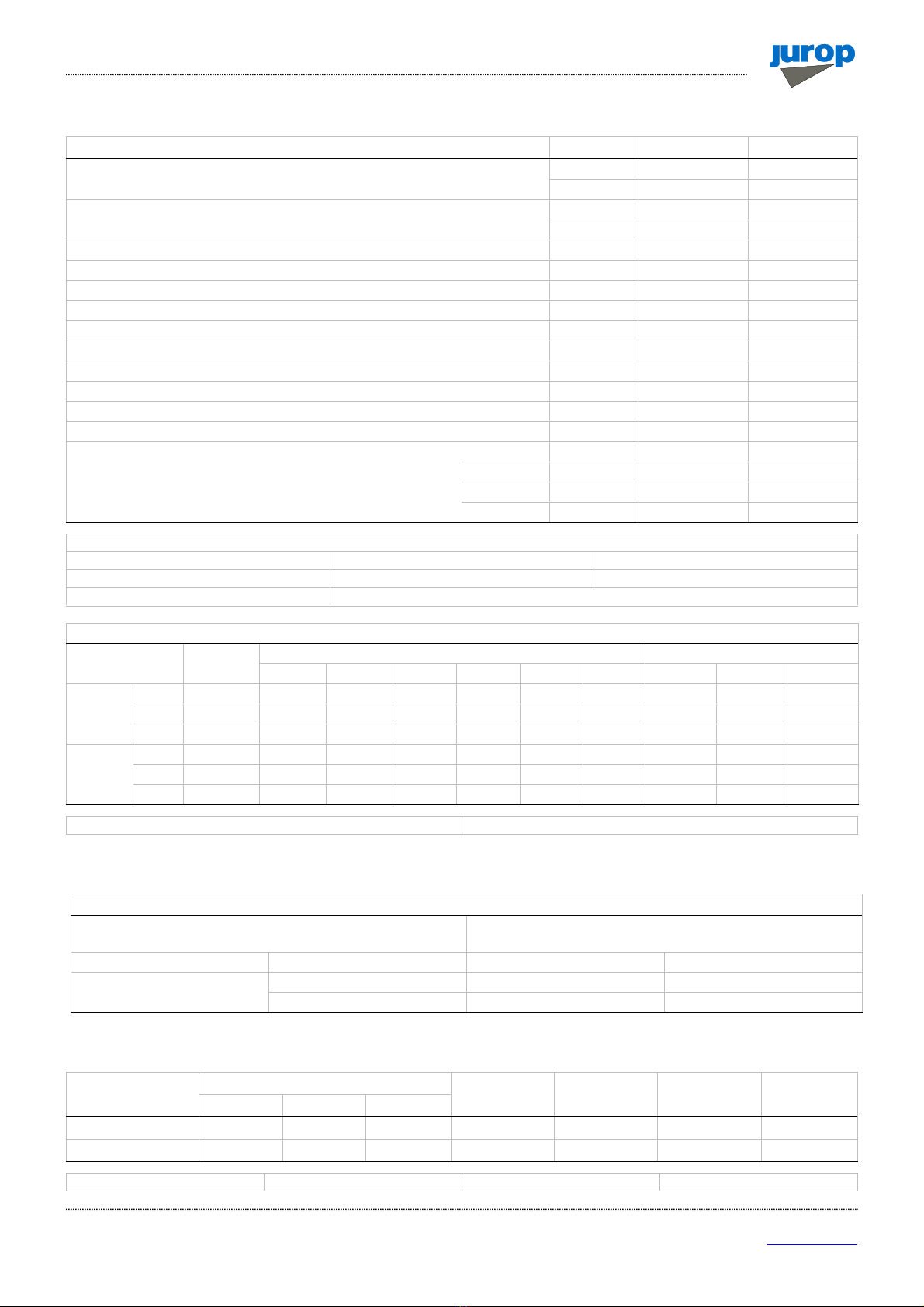

2.5. Lubrication

Recommended oils: Mineral oil anti-wear

Room T° Viscosity ENI ESSO SHELL TOTAL MOBIL BP TEXACO Q8

Under 10°C ISO VG 46 Acer 46 Nuto 46 Morlina S2 B 46 Drosera MS 46 Nuto H 46 Bartran HV 46 Rando HD 46 Shubert 46

Over 10°C ISO VG 150 Acer 150 Nuto 150 Morlina S2 B 150 Drosera MS 150 Nuto H 150 Bartran HV 150 Rando HD 150 Shubert 150

Attention:

Carefully apply these prescriptions.

3.1. General recommendations

• When transporting the compressor use proper slinging. Store the

compressor in stable places.

• Installation and maintenance must be carried out with the unit

totally disengaged from its drive system and must be performed by

qualified personnel.

• Use adequate clothing (avoid ties, loose sleeves, necklaces and

so on) and suitable protection equipment (gloves, protection glasses,

boots...).

• Before each maintenance operation, stop the pump and restore

the atmospheric pressure.

• Make sure that all the parts of the unit are idle and cool, before

performing any maintenance operation.

• To prevent errors and hazardous situations, establish what each

operator is responsible for in the different maintenance operations.

• Do not start the machine if the protection devices provided for

transmissions are removed. Replace damaged part.

• Final manufacturer must make the transmission inaccessible by

means of a fixed guard or interlocked movable guard.

• Operators working nearby must avoid prolonged exposure to the

noise emitted by the aspirator, if not equipped with the proper ear-

protection devices (IPDs recommended: ear protectors).

• When the pump is running, some parts may reach very high

temperatures (above 70°C). Use all necessary precautions to avoid

contact.

• Avoid accidental suction of solids: solids may be projected at high

speed through the exhaust manifold and cause injures. A filter must be

mounted on the suction line (Mesh 55).

• Pressure relief valve: point the air flux away from the operators.

• Do not use the aspirator over its designed limits: the machine may

be damage and the operator may be injured.

Do not exceed the speed and the power supply

parameters indicated in the technical tables (see

par 2.2 – 2.4).

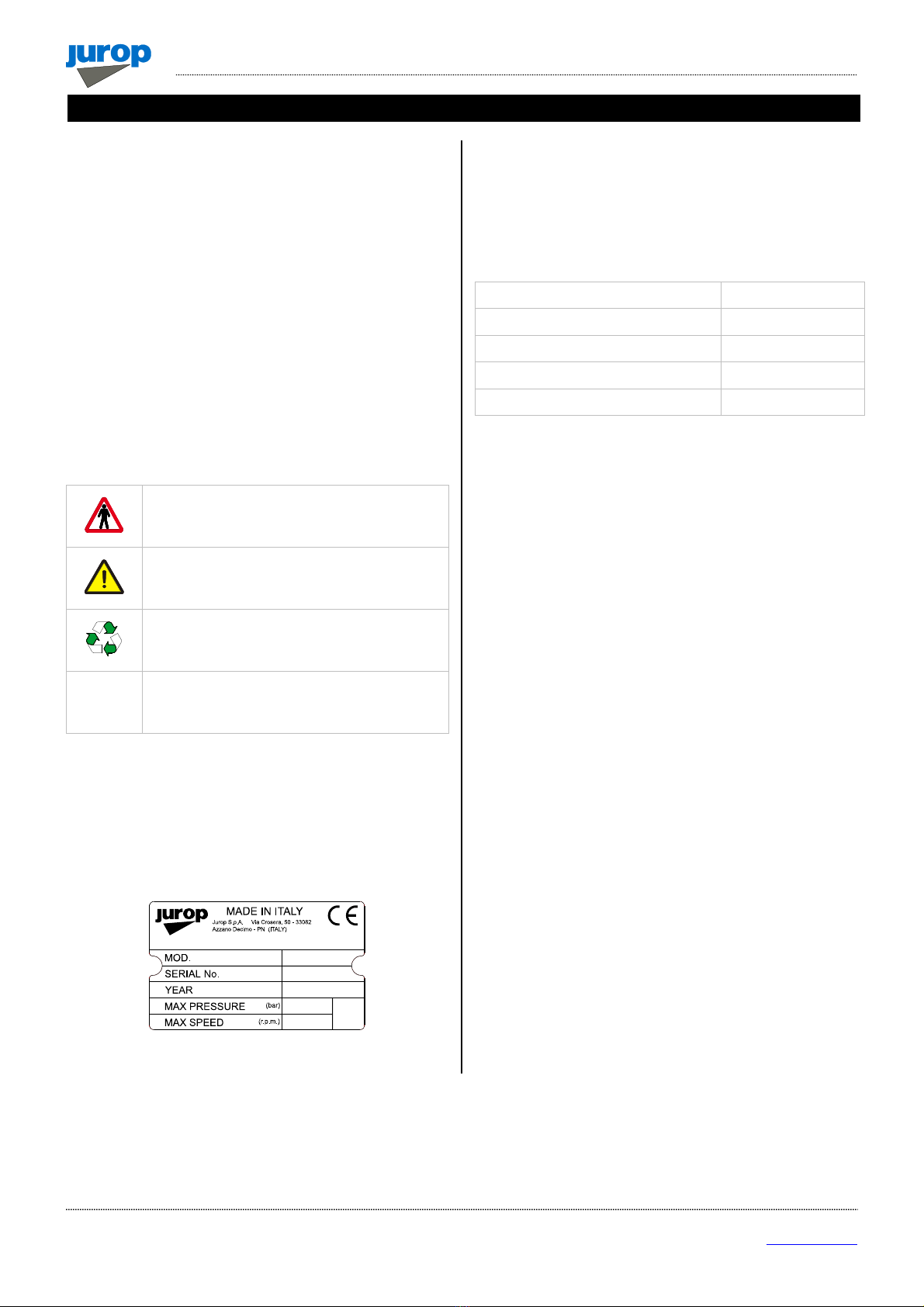

• Based on the final use of the decompressor, the insertion in the

housing machine and the typology of the same, the designer of the

housing machine must apply safety signals (pictograms) to warn the

operator on the risk still present. These pictograms essentially refer to

three categories:

Signals prescribing the use of Individual Protection Devices (IPDs)

such as, in this case, the use of gloves and ear protectors.

Signals indicating to pay particular attention to the dangers related

to the machine’s components, such as: risk of dragging in the

transmission equipment and contact with hot surfaces.

Signals indicating specific parts of the machine for an easier

identification, such as: greasing points, oil tanks, etc.

3.2. Intended use

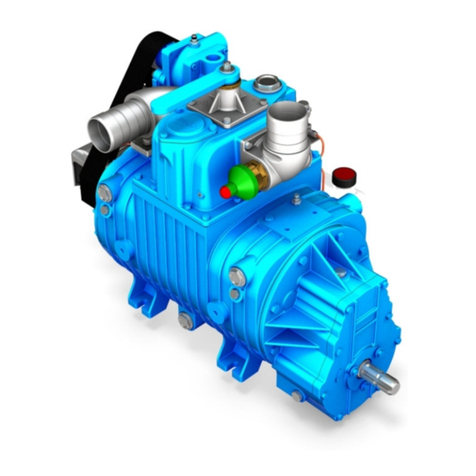

• The vacuum pumps RV are designed to convey filtered air into

systems for the vacuum production (example: systems for the suction

of powders or liquid wastes). Any other usage shall be considered

improper.

• Do not sack toxic substances and inflammable or explosive

gasses, since the internal components of the pump may reach high

temperatures.

Avoid suction of toxic (poisonous) explosive or

flammable gasses because internal components

may reach high temperatures.

• Avoid suction of liquids or solids; they can seriously damage the

pump.

Attention: liquids or solids infiltrations can

seriously damage the pump.

• Do not run the pump over its designed operating limits (see par.

2.5): it may break and transmission can be damaged.

3.3. Conveyed fluids

• RV are suitable for conveying filtered air. Before conveying other

kind of gases, verify compatibility with pump’s characteristics.

• The machine was not designed and built to operate in

environments with potentially explosive atmosphere (outdoor or

indoor).

• Please contact JUROP’s Technical dept. if necessary.

3. Safety and accident prevention