Fuel quality can effect a vehicle’s performance.

Specifically, gasoline and gasoline blends that

are contaminated or contain excessive amounts

of ethanol can effect vehicle driveability, fuel

economy, fuel system components and emissions.

Due to the potential negative impact of poor fuel

quality, it is important for today’s technician to

have the capability to correctly diagnose fuel

related concerns.

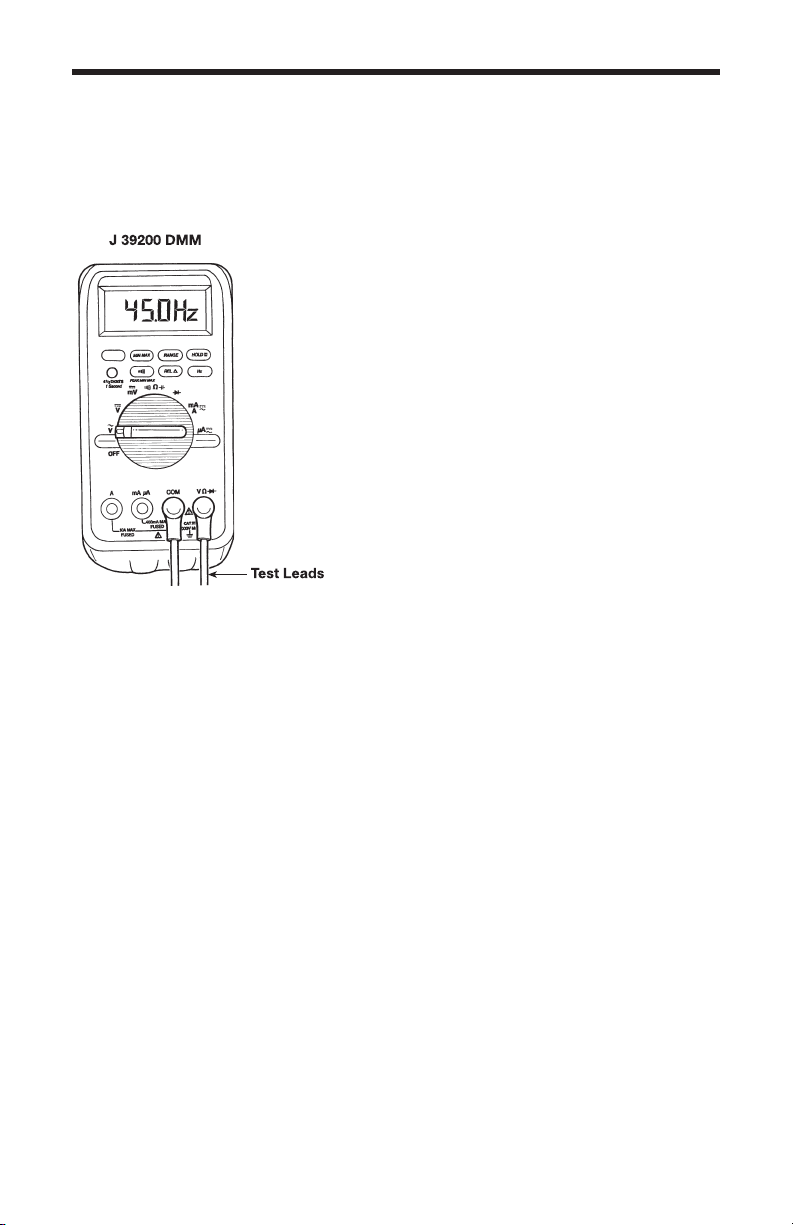

Tool Description

The Fuel Composition Tester J-44175-A is a

microprocessor based hand held tester to allow

for accurate analysis of gasoline and gasoline/

ethanol blends. It is easy to use and designed to

be used with a Digital Multi Meter (AC frequency

Hz scale), to quickly indicate the ethanol percentage

of any fuel sample. When testing “E85”, which

should measure between 60% and 91% ethanol,

the tester’s red LED will indicate if the fuel is

contaminated and should be replaced. The red-

colored LED can indicate certain contaminants

such as methanol or very small amounts of salt.*

If methanol is in the fuel, the fuel is contaminated

and should be replaced. Methanol can corrode

metal parts in the fuel system and also can

damage plastic and rubber parts. The J-44175-A

can indicate methanol in one of two ways: either

by frequency measurement above 160, or the red

LED on, or both.

The Fuel Composition Tester

J-44175-A is designed to be used with the

J-39200 Digital Multi Meter (DMM) in order to

display a frequency (Hz) value. This frequency

value is easily converted to indicate ethanol

*During certain atmospheric conditions, it is possible for very small amounts of salty air to enter the vehicle fuel

tank through the evaporative emissions system fresh air vent. If the amount of salt in the fuel becomes

sufficient to light the tester’s red LED, the fuel is contaminated and should be replaced. See “J-44175-A

frequency measures above 160 Hz, and/or the red LED is on” in the appendix.

INTRODUCTION

4