DeFelsko PosiTector SST User manual

Quick Guide v. 1.0

The Measure of Quality

Soluble Salt Tester

The Bresle Method DeFelsko Patch is low cost, latex-free,

and works on nearly any surface geometry or material.

It features a low-tack adhesive which creates a

tight seal while remaining easy to remove without

leaving behind any foam residue.

The Bresle Method DeFelsko PosiPatch further simplifies the

Bresle method. It requires no adhesive, as it is held to a steel

surface by a magnetic holding ring. It has a built-in port

which allows

deionized (DI) water to be injected

using a dull polypropylene dispensing tube,

eliminating sharp needles from the test. It

features a patented air-permeable membrane,

which automatically releases trapped air as DI

water is injected, then allows air bubbles to return

and agitate the surface as solution is withdrawn. It is also

reusable, and a single PosiPatch can be used for multiple tests.

The PosiTector SST can be used as a conventional conductivity

meter making it ideal for testing abrasive materials in accordance

with ISO 11127-6 and ASTM D4940-15. See Bresle Mode (pg. 9)

This Quick Guide summarizes the basic functions of the gage.

Download the full instruction manual at www.defelsko.com/manuals

Recommended: PosiTector SST Video -

www.defelsko.com/sst/video

Introduction

The PosiTector Soluble Salt Tester (SST) is a hand-held

electronic instrument that measures the conductivity of a solution

and calculates the concentration of water-soluble salts on metal

surfaces in accordance with ISO 8502-6 (the Bresle Method) and

ISO 8502-9. It consists of a PosiTector body (Standard or

Advanced) and an interchangeable probe

The PosiTector SST is compatible with all Bresle Method-type

patches including the Bresle Method DeFelsko PosiPatch, Bresle

Method DeFelsko Patch and other adhesive patches. While

compatible with any test patch, there are numerous advantages

to the DeFelsko patch solutions.

1

PosiTector SST

probes consist of a purpose-built test cell, optimized

for the range, resolution and test volume of the Bresle Method.

Conductivity measurements are compensated to 25°C

(77°F) using a built-in temperature sensor, and the

sample temperature is recorded for each measurement.

The probe can be used as a conventional conductivity

meter by unchecking Bresle Mode (pg. 9).

When powered-up, the PosiTector automatically

determines which probe is attached and does a self-check.

To disconnect disconnect a probe from a body, slide the

plastic probe connector horizontally (in the direction of the

arrow) away from the body. Reverse these steps to attach

a different probe. It is not necessary to power-down the

Gage when switching probes.

To navigate, use the Up and Down buttons to scroll vertically

and to SELECT.

Menu Operation

Press the (+)button to switch

pages in a multipage menu

Press the

(-)

button to return to

the previous menu or page.

Select Exit to exit from any menu.

Test

Cell

2

Basic Operation

The PosiTector SST powers-up when the center navigation

button is pressed. To preserve battery life, the Gage powers

down after approximately 5 minutes of no activity (15 minutes

while in Bresle Mode (pg. 9). Alternatively, select Power Off

from the menu. All settings are retained.

Gage functions are menu controlled. To access the Menu,

power-up the gage, then press the center navigation button.

Probes

The PosiTector gage body accepts a wide variety of probe

types including magnetic, eddy-current and ultrasonic coating

thickness, surface profile, environmental, Shore hardness

durometer and ultrasonic wall thickness probes.

See www.defelsko.com/probes

3

How To Measure

Test Preparation:

Use deionized (DI) water to thoroughly clean the PosiTector SST

test cell, test cup, syringe and PosiPatch (if used in test).

All test materials should be handled in a manner that minimizes

the potential for contamination. The PosiTector SST operator may

choose to wear nitrile or other non-contaminating gloves when

performing the test.

Remove the protective rubber cap from the probe. Power-up the

Gage by pressing the center navigation button.

In the default Bresle Mode, the Gage guides you through three

simple steps –

[1], [2], and [3].

Step

[1]:

Obtain Background (Blank) Conductivity Measurement (γ1)

NOTE: The Gage automatically displays the previous background

measurement, if any. This measurement can be reused and step

(c) to step (e) can be skipped by pressing the (

-

) button.

a) Pour at least 4ml (milliliters) of deionized (DI) water into the

supplied cup (to prevent contamination of the water source).

b) Fill the syringe completely with DI water from the cup (slightly

more than 3ml).

c) Completely fill the PosiTector SST probe’s test cell with water

from the syringe (approximately 1ml).

d) Wait until the measurement stabilizes (up to 5 seconds),

then press the (+) button to save a new background conductivity

measurement (

γ

1) and the water temperature (T1).

e) Use the syringe to draw all of the water from the test cell.

Shake any remaining water out of the test cell.

f) With the syringe pointing up, expel the air and excess solution

from the syringe until there is 3.0ml of DI water remaining.

Step

[2]:

Prepare Bresle Method Patch

Option A: DeFelsko PosiPatch

a) Turn the PosiPatch and magnetic ring upside down. Place

the PosiPatch into the magnetic ring ensuring the arrows align

with the injection port. Do not touch the PosiPatch’s interior.

b) Carefully place the magnetic ring on the steel surface.

When used on vertical surfaces, position the port between the

2 o’clock and 10 o’clock points before attaching the ring to the

surface.

c) Slowly inject 3.0ml of DI water into the port using the plastic

dispensing tip. The air within the PosiPatch automatically

escapes through the air-permeable membrane

4

(a) (b) (c)

When used on horizontal surfaces, fully insert the dispensing tip

into the PosiPatch. On vertical surfaces, insert the dispensing tip

only as far as is needed to see the tip inside the PosiPatch.

Option B: Bresle Method DeFelsko Patch (or equivalent)

a) Remove the backing and foam center from the patch, taking

care not to touch the interior surface.

b) Press the patch firmly onto the surface making sure most of

the air escapes.

c) Pierce the top of the patch at the foam perimeter, allowing

the needle to penetrate into the center of the patch.

5

d) Inject half of the water into the patch. Then, use the syringe

to withdraw trapped air.

e) Remove the needle, point it upwards and expel the air.

f)

Re-insert the needle and inject the remaining water into the patch.

Step

[3]:

Begin Test (applies to both patch styles)

a) Once the water is injected into either patch,

press the (+)button to start the test timer.

After starting the test timer, the operator can select Power Off

from the Gage menu to conserve battery life. The test timer will

continue to run and the elapsed test time will be displayed when

the Gage is powered-up.

b) Without removing the needle/dispensing tip from the patch,

use the syringe to repeatedly withdraw and inject the water. ISO

8502-6 recommends this process be completed at least four

times and that the test time be agreed between interested parties.

c) After the desired amount of time has elapsed, withdraw the

solution from the patch.

d) To complete the measurement, completely fill the PosiTector

SST probe’s test cell with the solution from the patch. Wait until

the measurement stabilizes(up to 5 seconds), then press the (+)

button to save the temperature (T2) and conductivity (

γ

2) of the

solution. ∆

γ

, the difference between the

γ

2soluble salt reading

and the

γ

1background reading, is displayed.

(a) (b) (c)

TIP:

t= test duration

T2= sample temperature

∆

γ

= The change in conductivity. The

initial background measurement (

γ

1)

is automatically subtracted from the

final measurement (

γ

2) Test results

are displayed in units of microsiemens

per centimeter (conductivity).

ρA=The surface density of soluble

salt expressed as sodium chloride.

Test results are displayed in units of

milligrams per square meter, or

micrograms per square centimeter.

If a memory batch is open, the measurement result will be stored

in memory (pg. 9).

e) Press the (+) button to begin a new test.

Patch Removal

The Bresle Method DeFelsko Patch peels off the surface easier

and with less residue than conventional Bresle patches. Remove it

immediately after the test and dispose.

The Bresle Method PosiPatch lifts

cleanly off the surface, with absolutely

no residue. The user may choose to

discard the PosiPatch and begin the

next test with a new one, or simply

rinse it with DI water and reuse for

several more tests until worn.

Rinsing the Test Cell

Rinse the test cell with unused DI water

several times after each measurement,

shaking the water out after each rinse.

6

7

Calibration, Verification, and Adjustment

Three steps ensure best accuracy…

1. Calibration: typically performed by the manufacturer. All probes

include a Certificate of Calibration.

2. Verification of Accuracy: typically performed by the user

by measuring known reference standards such as the supplied

conductivity standard.

3. Adjustment: to a known conductivity standard

.

Calibration - Calibration is the high-level, controlled and

documented process of measuring traceable calibration standards

over the full operating range of the probe, and verifying that the

results are within the stated accuracy of the probe. Calibrations

are performed by the manufacturer, their authorized agent, or by

an accredited calibration laboratory in a controlled environment

using a documented process.

Verification of Accuracy - Verification is an accuracy check

performed by the user with a solution of known conductivity. To

perform a verification, ensure that the conductivity standard and

instrument are at the same temperature. Remove any remaining

DI water in the test cell by filling it with the conductivity standard,

then inverting the test cell to empty it. Fill the test cell with the

conductivity standard again. If the reading is not within the

combined tolerance of the gage and conductivity standard,

proceed to Cleaning the Test Cell, below.

Cleaning the Test Cell - If the Verification reading is outside the

combined accuracy of the conductivity standard and gage, the

probe may need to be cleaned by filling it with DI water and rubbing

the walls of the cell with a supplied foam tip swab. Rinse with DI

water several times before using the cell.

Verify accuracy at the beginning and the end of each work shift.

During the work shift, if the Gage is dropped or suspected of giving

erroneous readings, its accuracy should be re-verified.

Adjustment - Adjustment, or Calibration Adjustment, is the act of

aligning the Gage’s readings to match that of a known conductivity

standard. (see Cal Adjust, pg. 9)

Reset (menu Reset) restores factory settings and returns the

Gage to a known condition. The following occurs:

-

All batches, stored measurements, batch names and screen

captures are erased.

-

Calibration adjustments are returned to factory settings.

-

The last stored background measurement (

γ

1) is erased.

-

Menu settings are returned to the following:

1. Power down the Gage and wait 5 seconds.

2. Simultaneously press and hold the (+)and center

buttons until the Reset symbol appears.

This returns the Gage to a known, “out-of-the-box” condition.

Set the volume of water being used for the test (3.0ml default).

Use the (

-

)(+) buttons to decrease/increase the displayed value.

The patch volume is used to calculate surface density.

Patch Volume

8

Reset

Setup Menu

Memory = OFF

Bresle Mode = ON

Auto Dim = ON

Display = None

Patch Volume = 3.0ml

Bluetooth & Stream = OFF

WiFi & Access Point = OFF

Surface Density units = mg/m2

Temperature units = °C

Hi Res = OFF

Units

Allows the operator to change the displayed units for both

Temperature (°C or °F) and Surface Density (mg/m2or µg/cm2).

Perform a more thorough Hard Reset as follows:

Flip Display = Normal

Backlight = Normal

Auto Sync .net = ON

White on Black = ON

Sound = ON

Language = English

Battery Type = Alkaline

Bluetooth Smart = OFF

USB Drive = ON

It performs the same function as a menu Reset with the addition of:

-

Bluetooth Pairing info is cleared.

-

Menu settings are returned to the following status:

-

Date, Time and WiFi settings are not affected by either Reset.

NOTE:

The PosiTector SST can be adjusted to a known conductivity

standard. Use the (

-

)(+) buttons to decrease/increase the

displayed value to match the known conductivity of the standard.

In typical use, a calibration adjustment should not be

required. Before performing the adjustment, ensure that the

PosiTector SST test cell has been thoroughly cleaned with

DI water. Ensure that the conductivity standard and

PosiTector SST test cell are at the same temperature.

Cal Adjust

When checked

(default),

the Gage guides the user through a 3-step

test process in accordance with

ISO 8502-6.

Uncheck Bresle Mode

to use the PosiTector SST as a regular conductivity meter such as

when testing abrasive materials in accordance with ISO 11127-6

and ASTM D4940-15.

Bresle Mode

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium” or “NiMH” (nickel-metal hydride rechargeable).

If “NiMH” is selected, the Gage will trickle charge the batteries while

connected via USB to a PC or optional AC power supply (USBAC).

The battery state indicator symbol is calibrated for the selected

battery type. No damage will occur if the battery type used in the

Gage does not match the selected battery type.

Battery Type

The PosiTector SST has internal memory storage for recording

measurement data. Stored measurements can be reviewed on-

screen or accessed via computers, tablets and smart phones.

All stored measurements are date and time-stamped.

The symbol appears when the Gage is set to store

measurement data.

Memory Management

9

Increases the displayed Gage resolution as follows:

0.1 µS, 0 - 200 µS

1.0 µS, over 200 µS

Gage accuracy is not affected.

Hi Res

NOTE:

NOTE:

(Calibration Adjustment)

10

Screen Capture

Press both the (

-

)and (+)buttons at any time to capture and save

an image copy of the current display. The last 10 screen captures

are stored in memory and can be accessed when connected to a

computer (see PosiSoft USB Drive, pg. 10).

Accessing Stored Measurement Data

DeFelsko offers the following free solutions for viewing, analyzing

and reporting data:

PosiSoft USB Drive - Connect the Gage to a PC/Mac using the

supplied USB cable. View and print readings and graphs using

universal PC/Mac web browsers or file explorers. No software or

internet connection required. USB Drive must be selected in the

Gage’s “Connect > USB” menu (pg. 11).

PosiSoft Desktop - Powerful desktop software (PC/Mac) for

downloading, viewing, printing and storing measurement data.

Includes a customizable, templated PDF Report Generator. No

internet connection required.

PosiSoft.net - Web-based application offering secure, centralized

storage of measurement data. Access your data from any web-

connected device.

PosiTector App - (Advanced models only, serial numbers 784000+)

App for compatible iOS and Android smart devices. Permits users

to create, save and share professional PDF reports. Add images

and notes using the smart device’s camera and keyboard.

For more information on our PosiSoft solutions, see:

www.defelsko.com/posisoft

Advanced models store 100,000 readings in up to 1,000

batches. “New Batch” closes any currently opened batch and

creates a new batch name using the lowest available number.

New batch names are date-stamped when they are created.

Standard models store up to 250 readings in one batch.

The above WiFi,USB and Bluetooth menus contain a Sync .net

Now option. When selected, the Gage immediately synchronizes

stored measurement data via its respective communication

method (internet connection required). Alternatively, select Auto

Sync .net from within the USB connect menu to automatically

synchronize upon connection to a PC. Additional measurements

added to memory while connected are synchronized only when

the USB cable is disconnected and reconnected, or when the

Sync.net Now option is selected. WiFi connected gages

automatically attempt synchronization upon power-up.

Sync .net Now

Connect Menu

When USB Drive is checked , the PosiTector gage uses

a USB mass storage device class which provides users with a

simple interface to retrieve stored data in a manner similar to

USB flash drives, digital cameras and digital audio players.

USB Drive is also required to import stored measurements into

PosiSoft Desktop software (pg. 10).

When connected, power is supplied through the

USB cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiMH) batteries

are installed, the instrument will trickle charge the batteries.

Allows individual readings to be sent to a computer, printer or

compatible device as they are taken using Bluetooth wireless

technology. See www.defelsko.com/bluetooth

Bluetooth (Advanced models only)

Allows connection to your local wireless network or mobile

hot spot. Ideal for using your network’s internet connection for

synchronizing stored measurements with PosiSoft.net (pg. 10).

See www.defelsko.com/wifi

WiFi (Advanced models only)

NOTE:

USB

PosiSoft Desktop Manager is required when using

USB or Bluetooth connections to synchronize measurements

with PosiSoft.net.

NOTE:

11

12

Sync Batches

Select batches to flag them for synchronization to the

PosiTector App. New batches created while Bluetooth Smart

is enabled are automatically selected.

With Bluetooth Smart enabled, select Sync Batches to transfer

selected batches to the PosiTector App. This is useful when

switching between smart devices, as only readings and batches

that have yet to be synchronized with any smart device are

synchronized automatically.

The Gage will perform a Hard Reset (pg. 8) after

an update. All stored measurements will be erased from memory.

Updates

Determine if a software update is available for your Gage.

See www.defelsko.com/update

WARNING:

When Enabled , allows communication with a smart device

running the PosiTector App (pg. 10) via auto-pairing Bluetooth

Smart (BLE) wireless technology.

Bluetooth Smart (Advanced models only,

serial numbers 784000 and greater)

Send Batches

Transfers selected batches to the PosiTector App (useful

when switching between devices).

The Send Batches option is visible in the Bluetooth Smart

menu when the Gage is connected to a smart device running

the PosiTector App.

If Bluetooth Smart is disabled, data from batches

selected in the Sync Batches menu are held in a queue until

communication with the PosiTector App is re-established.

NOTE:

www.defelsko.com

© 2016 DeFelsko Corporation USA

All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko, PosiSoft and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and

in other countries. Other brand or product names are trademarks or registered trademarks of their

respective holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

Returning for Service

Before returning the instrument for service…

1. Install new or newly recharged batteries in the proper

alignment as shown within battery compartment.

2. Examine the probe for damage. Use the supplied cleaning

tool to clear dirt or debris from the test cell.

3. Perform a Hard Reset (pg. 8).

4. If issue is not resolved, Update (pg. 12) your PosiTector

gage body and re-attempt measurements.

IMPORTANT:

If you must return the Gage for service, please fill out and

include the Service Form located at www.defelsko.com/support

with the Gage. Be sure to also include the probe, your company

name, company contact, telephone number and fax number or

email address.

Limited Warranty, Sole Remedy

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

13

The Measure of Quality

Soluble Salt Tester

Guía rápida v. 1.0

Introducción

El PosiTector Soluble Salt Tester (

SST

) es un instrumento

electrónico portátil que mide la concentración de una solución y

calcula la concentración de sales solubles en superficies de metal

de acuerdo con la norma ISO 8502-6 (método Bresle) e ISO 8502-9.

Se compone de una base PosiTector (Standard o Advanced) y una

sonda intercambiable.

El

PosiTector SST

es compatible con todos los parches para el

método Bresle incluyendo el PosiPatch DeFelsko para método

Bresle, los parches para método Bresle DeFelsko y otros parches.

Al tiempo que es compatible con cualquier parche de prueba, presenta

numerosas ventajas con las soluciones de parches DeFelsko.

1

El Parche DeFelsko para método Bresle tiene un bajo

coste, no contiene látex, y funciona en casi cualquier

geometría de la superficie o material. Cuenta con un

adhesivo de baja adherencia que crea un sello hermético que

es fácil de quitar sin dejar ningún residuo de espuma.

El PosiPatch DeFelsko para método Bresle simplifica aún más la

prueba. No requiere ningún adhesivo, ya que está unido a una

superficie de acero por un anillo de retención magnética.

Dispone de un punto de entrada de agua desionizada

(DI) que se inyecta usando una cánula de dosificación

de polipropileno de punta roma eliminando las agujas

punzantes de la prueba. Cuenta con una membrana

permeable al aire patentada que libera automáticamente

el aire de su interior cuando se inyecta agua desionizada, lo que

permite que las burbujas de aire retornen y agiten la superficie al

extraer la solución. Tiene varios usos y un solo PosiPatch puede

utilizarse para múltiples pruebas.

El PosiTector SST puede utilizarse como un medidor de

conductividad convencional, lo que es ideal para pruebas de

materiales abrasivos según ISO 11127-6 y ASTM D4940-15.

Consulte Modo Bresle (pág. 8).

Esta guía rápida recoge las funciones básicas del medidor.

Descargue el manual de instrucciones completo en

www.defelsko.com/manuals.

Recomendado: Vídeo PosiTector SST: www.defelsko.com/sst/video

Sondas

Una vez encendido, el PosiTector determinará automáticamente el tipo

de sonda conectado y realizará una comprobación automática.

Para desconectar una sonda de la base del PosiTector

deslíce el conector de la sonda de plástico horizontalmente

(en la dirección de la flecha)

separándola de la base

PosiTector

.

Invierta los pasos para conectar una sonda diferente. No es

necesario apagar el medidor cuando se cambia la sonda.

La base del medidor PosiTector acepta una amplia variedad

de tipos de sonda incluyendo las necesarias para medir espesor

de recubrimientos tipo magnético, de corrientes de Foucault

y de ultrasonido; sondas para perfiles de superficie, ambiental, dureza

Shore y sondas de espesor de pared por ultrasonidos. Consulte

www.defelsko.com/probes

Las sondas PosiTector SST son celdas de ensayo especialmente

diseñadas y optimizadas para el intervalo, resolución y

volumen de prueba del método Bresle. Las mediciones

de conductividad se compensan a 25°C (77°F) utilizando

un sensor de temperatura incorporado registrándose la

temperatura de la muestra para cada medición. La sonda

puede utilizarse como un medidor de conductividad

convencional desactivando el Modo Bresle (pág.8).

El PosiTector SST se enciende al pulsar el botón central . Para

preservar la vida de la batería, el medidor se apagará tras unos 5 minutos

sin actividad (15 minutos en el Modo Bresle, pág. 8). Como alternativa,

seleccione Apagar en el menú. Se conservarán todas las configuraciones.

Funcionamiento Básico

Menú Operación

Las funciones del medidor se controlan con un menú. Para acceder al

menú encienda el medidor y pulse el botón central.

Presione el botón (+) para cambiar

de página en el menú formado de

varias páginas.

Presione el botón (

-

)para regresar

al menú o página anterior.

Seleccione Salir para cerrar el

menú del medidor.

Para desplazarse utilice los botones Arriba y Abajo y para

SELECCIONAR.

Celdas de ensayo

2

3

Cómo medir

Retire el tapón protector de goma de la sonda. Encienda el medidor

pulsando el botón central . En el modo por defecto

Bresle

,el

medidor le guiará a través de tres pasos muy simples

–

[1], [2],y[3].

Paso

[1]:

Obtener la medición (γ1) de la conductividad de fondo

(en blanco)

NOTA:

El medidor mostrará de manera automática la medición de

fondo anterior, si hubiera. Esta medición podrá volver a utilizarse y

podrá omitir los pasos de

(c)

a

(e)

presionando el botón (-).

a)

Vierta al menos 4ml (mililitros) de agua desionizada (DI) en el

recipiente para evitar la contaminación de la fuente de agua.

b)

Llene completamente la jeringa con el agua del recipiente.

c)

Llene completamente la celda de prueba de la sonda del

PosiTector SST

con el agua de la jeringa.

d)

Pulse el botón (+) para guardar una nueva medición de la

conductividad de fondo

(

γ

1)

y la temperatura del agua

(T1)

.

e)

Utilice la jeringa para extraer toda el agua de la celda de prueba.

Elimine cualquier resto de agua de la celda de prueba.

f)

Expulse el aire y el exceso de solución de la jeringa apuntando

hacia arriba hasta que queden 3ml.

Paso

[2]:

Preparar el método Bresle

Opción A: PosiPatch DeFelsko

a)

Gire el PosiPatch y el anillo magnético dejando su cara superior

hacia abajo. Coloque el PosiPatch en el anillo magnético alineando las

flechas con el punto de inyección. No toque el interior del PosiPatch.

b) Coloque con cuidado el anillo magnético sobre la superficie de acero.

c)

Inyecte lentamente el agua en el punto de entrada utilizando la

cánula de plástico. El aire del interior del PosiPatch se escapará

automáticamente a través de la membrana permeable al aire.

(a) (b) (c)

Opción B: Parche para método Bresle DeFelsko (o equivalente)

a)

Retire el refuerzo y el centro de espuma del parche con cuidado

de no tocar la superficie interior.

b)

Presione el parche firmemente contra la superficie asegurándose

de que sale la mayor parte del aire.

c) Perfore la parte superior del parche en el marco de espuma,

permitiendo que la aguja llegue al centro del parche.

4

(a) (b) (c)

d)

Inyecte la mitad del agua en el parche. A continuación utilice

la jeringa para extraer el aire del interior.

e)

Retire la aguja, apunte hacia arriba y expulse el aire.

f)

Vuelva a insertar la aguja e inyecte el agua restante en el parche.

Paso

[3]:

Iniciar la prueba (aplica a ambos estilos de parche)

a)

Una vez que haya inyectado el agua en cada parche, pulse el

botón (

+

) para iniciar el temporizador de prueba.

b)

Sin retirar la aguja o cánula del parche, utilice la jeringa para

expulsar e inyectar el agua repetidamente. La ISO 8502-6

recomienda completar este proceso al menos cuatro veces y que

el tiempo de prueba se determine entre las partes interesadas.

c)

Transcurrido el período de tiempo deseado, extraiga la solución

de parche.

d)

Para completar la medición, llene completamente el medidor de

celda de la sonda

PosiTector SST

con la solución del parche y

pulse el botón (

+

) para guardar la temperatura

(T2)

y la

conductividad

(

γ

2)

de la solución. Aparecerá

∆

γ, la diferencia

entre la lectura de sal soluble γ

2

y la lectura de fondo γ

1

.

t

= tiempo de prueba transcurrido

T2= temperatura de la solución

de prueba

∆

γ= cambio en la conductividad.

Automáticamente se restará la

medición de fondo inicial (γ

1

) de la

medición final (γ

2

) y los resultados

de la prueba se mostrarán en

unidades de microsiémens por

centímetro (conductividad).

ρ

A

= Densidad superficial de sal

soluble expresada como cloruro de

sodio. Los resultados de la prueba

se mostrarán en unidades de miligramos por

metro cuadrado, o microgramos por centímetro cuadrado.

Si estuviera abierto un lote de memoria el resultado de la medición

quedará almacenado (pág. 8).

e)

Pulse el botón (

+

) para comenzar una nueva prueba.

Retirada del parche

El Parche para método Bresle

DeFelsko se despega de la

superficie con mayor facilidad y menos residuos que los parches

Bresle convencionales. Retírelo inmediatamente después de la

prueba y deséchelo.

El

PosiPatch

para método Bresle se despega limpiamente de la

superficie, sin ningún residuo. El usuario podrá elegir entre desechar

el PosiPatch y comenzar la siguiente prueba con uno nuevo o

simplemente aclararlo con agua desionizada y reutilizarlo para varias

pruebas más, hasta su deterioro.

Aclarado de la celda de prueba

Aclare la celda de prueba con agua desionizada después

de cada medición.

5

Other manuals for PosiTector SST

3

Table of contents

Languages:

Other DeFelsko Test Equipment manuals

DeFelsko

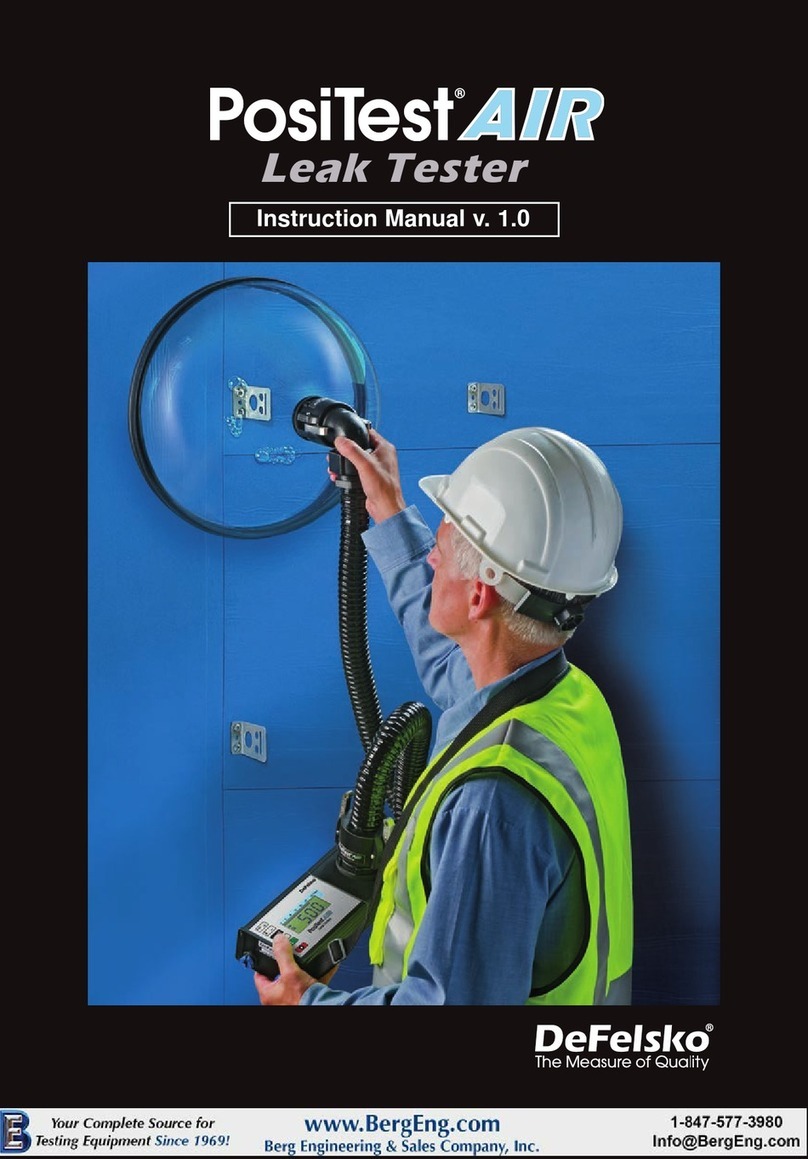

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTest AT-A User manual

DeFelsko

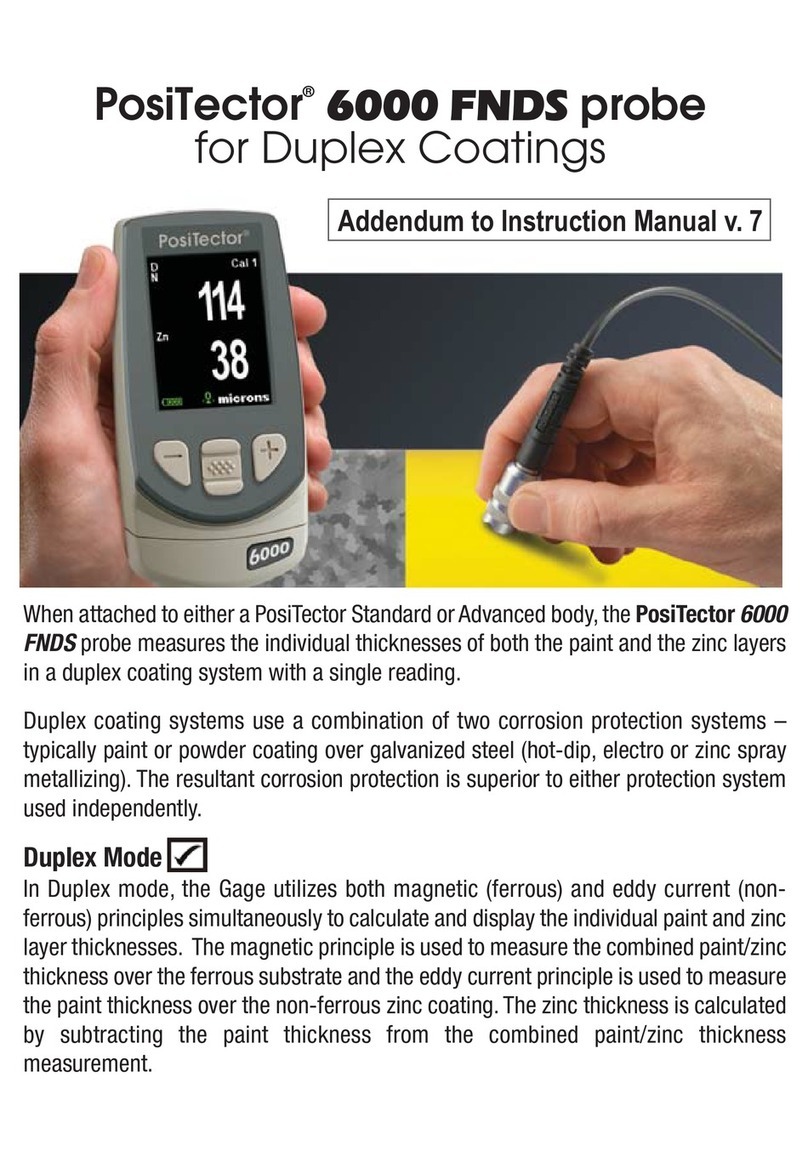

DeFelsko PosiTector 6000 FNDS Installation and operating instructions

DeFelsko

DeFelsko PosiTest AT-A User manual

DeFelsko

DeFelsko PosiTector UTG User manual

DeFelsko

DeFelsko PosiTector SPG User manual

DeFelsko

DeFelsko PosiTest DT User manual

DeFelsko

DeFelsko PosiTector SST User manual

DeFelsko

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTector 200 User manual