KENT USA KEB-CNC Series User manual

D

www.kentusa.com I 1.800.KENT.USA

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

- 1 -

Table of Contents

1. Introduction…………………………………………………….……………………..

1

1.1 Keys Symbol Description………………………………………………….…….

1

1.2 Hint Symbols………………………...…….…………………….……………….

1

1.3 Things to be careful…………….………………………………………….…….

1

1.4 Manual…………………………...………………………………………………..

2

2. Machine transportation and installation……………………………….................

1

2.1 Layout of the machine…………………………………………………………...

1

2.2 Installation site ………………………………….………………………...........

4

2.3 Transportation………………………………………………………..…………..

5

2.4 Machine installation……………………………………………………………...

7

2.5 Check before start the machine….…………………..….……………………..

14

3. Safety Directives……..………………………………………………………………

1

4. Machine service………………………………………………………………………

1

5. Systematic Specifications………………...…………………………………………

1

5.1 Hardware………………………………………..………………………….…….

1

5.2 Software……………………………...…………………………….……………..

1

6. Start and shut down the machine…………………………………………………..

1

6.1 Starting the machine………………….…….…………………………………...

1

6.2 Shut down the machine………………………..………………………………..

2

7. Operation..………………….…………………………………………………………

1

7.1 Screens Layout ………………………………………………………………….

1

7.2 Screen Layout of each system mode……………...…………………………

4

7.3 Layout of Control Panel and Descriptions………….…………………………

7

7.4 Illustration of functional buttons………………………………………..……….

11

8. Manual mode……………………………………………..…………………………..

1

0.

8.1 Home ………………….……………..……………………………….…………..

2

8.2 Edge ………………………………………………………………………………

3

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

- 2 -

8.3 INT.CAVITY………………………………………………………………………

5

8.4 EXT.CAVITY…………………………………………..………………………….

7

8.5 ATC (Option: ATC models)……………………………………………………..

11

8.6 REL_POS…………………………………………………………………………

17

8.7 ABS_POS…………………….……………..……….…………………………...

19

8.8 POS_SETUP………………………….……………………………….…………

21

8.9 POS_SAVE.……….……………………………………………………………...

23

8.10 Set a speed mode for manual wire control box……………….…………….

25

9. Operation mode…..………………………………………………………………..

1

9.1 INSERT……………………………………..…………..………………………..

9

9.1.1 POSITIONING………………………………………………….…………..

9

9.1.2 CUTTING……………………..……………….....………………………….

15

9.1.3 VECTOR………………………………………………………….…………..

26

9.1.4 SHAKE…………………………………....…………..…….....…………….. 33

9.1.5 IO-ON………..……………………………………..……………….……….

37

9.1.6 IO-OFF…………………………………….…………....………..…………

38

9.1.7 POSITION………………….………………………………….…………….

39

9.1.8 C_AXIS..……………………………………………………………..………

50

10.2 Re_WRITE………………………………………………………………………

.

61

10.3 COPY……………………………………………....…………....……………....

61

10.4 DELETE….………………..…………………………………………………….

61

10.5 CHANGE_POS…………...……………..……………………………………..

62

10.6 LOAD_FILE and SAVE_AS……….…………………………………………..

63

9.7 READY_SAVE…………………………….…………………………………......

64

10. C_CODE…...…………………………………………………...…………….…… 1

12. AI…………………………..……………………………………………….…….....

1

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

- 3 -

12. SYSTEM…………..…..………………………….…………………………………

1

12.1 PARA…....…………………………………….……..………………………….

2

12.2 TIME SET………………………………………………………………………

3

12.3 IN/OUT …………………………………………….…………………………...

4

12.4 MESSAGE..………………………………………..……………………………

5

12.5 DP_RAM..……….………………………………………………………………

8

12.6 USUAL……..…………………………………………………………………….

9

12.7 ATC………………………………………………………………………………

10

12.8 CLEAR LAG……………………….………………………..…………………..

10

12.9 RETURN……………………………………..………………………………….

10

13. Operation of dust stir………………………………………...……………………..

1

13.1 Start dust stir system manually……………………………………………….

2

13.2 Start the program of dust stir system…………………………………………

4

14. Graphite processing…………………………………………………………….….

1

15. Super Sparking……………………………………………………………………...

1

Appendix

Appendix 1

Appendix 2

KEB-CNC Machine Data Sheet

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

1. Introduction

- 1 -

1 Introduction

1.1 Keys Symbol Description

Symbols and Texts used in this manual, described as bellow:

Key Text Symbol Description

Function

Key:

Symbol used:【F1】Press【F1】

Key means press

Function Key

Text Key:Symbol used:<A>Press<A>

Key means press

Text Key

Input Key:Symbol used:『Enter』

Press『Enter』Key

Means press Input Key

1.2 Hint Symbols

Symbols used in this manual:

Symbols Description

⌦Warning This symbols means wrong operation will damage Operator.

!Note

This symbols means wrong operation will damage workpiece or

machine.

Hint This symbols means useful information is provided.

1.3 Things to be careful

⌦Danger 1. Do no touch electrode while discharging。

The Electrode has high voltage while discharging. Do not

touch electrode to prevent electrical shock.

2. Do not open the Power Generator while the Machine

power is ON. There is high voltage in Power Generator

while the power is on. Do not open the power generator to

prevent electrical shock.

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

1. Introduction

- 2 -

!Note

Hint

1.4 Manual

This manual is design for EDM KEB-CNC series, especially is for system

operation and program editing purpose.

* Please back up programs, machining parameters,

machining conditions and other parameters.

Programs, machining condition and parameters are saved

in memory chips. Even the power off, machine still keep

all the information.

* Unfortunately, some information might be lost due to the

wrong operation or machine error. Operator always can

reload the information from the back up disk.

*Parameters:

Please setup the right parameters。

Wrong parameters might cause of the machine

malfunction. Parameters are very important to the machine.

*Back up Disk:

Back up program is necessary.

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2.Machine transportation & Installation

1

2. Machine transportation and installation

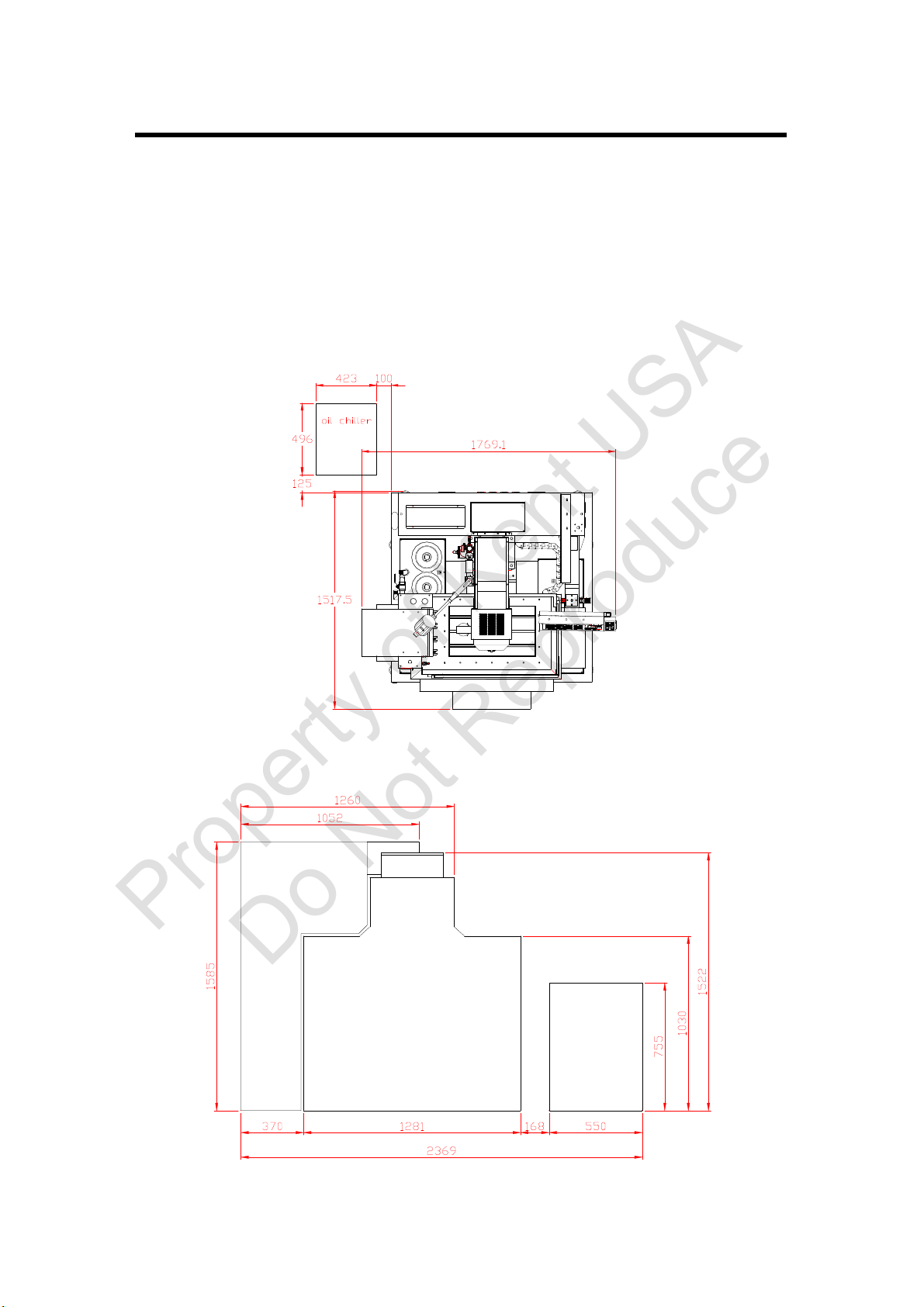

2.1 Layout of the machine

For the floor occupied by each mode of the machine, refer you to the

following layouts.

KEB-433CNC unit: mm

KEB-600LCNC unit: mm

machine

Oil tank

Electric

control

box

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2.Machine transportation & Installation

2

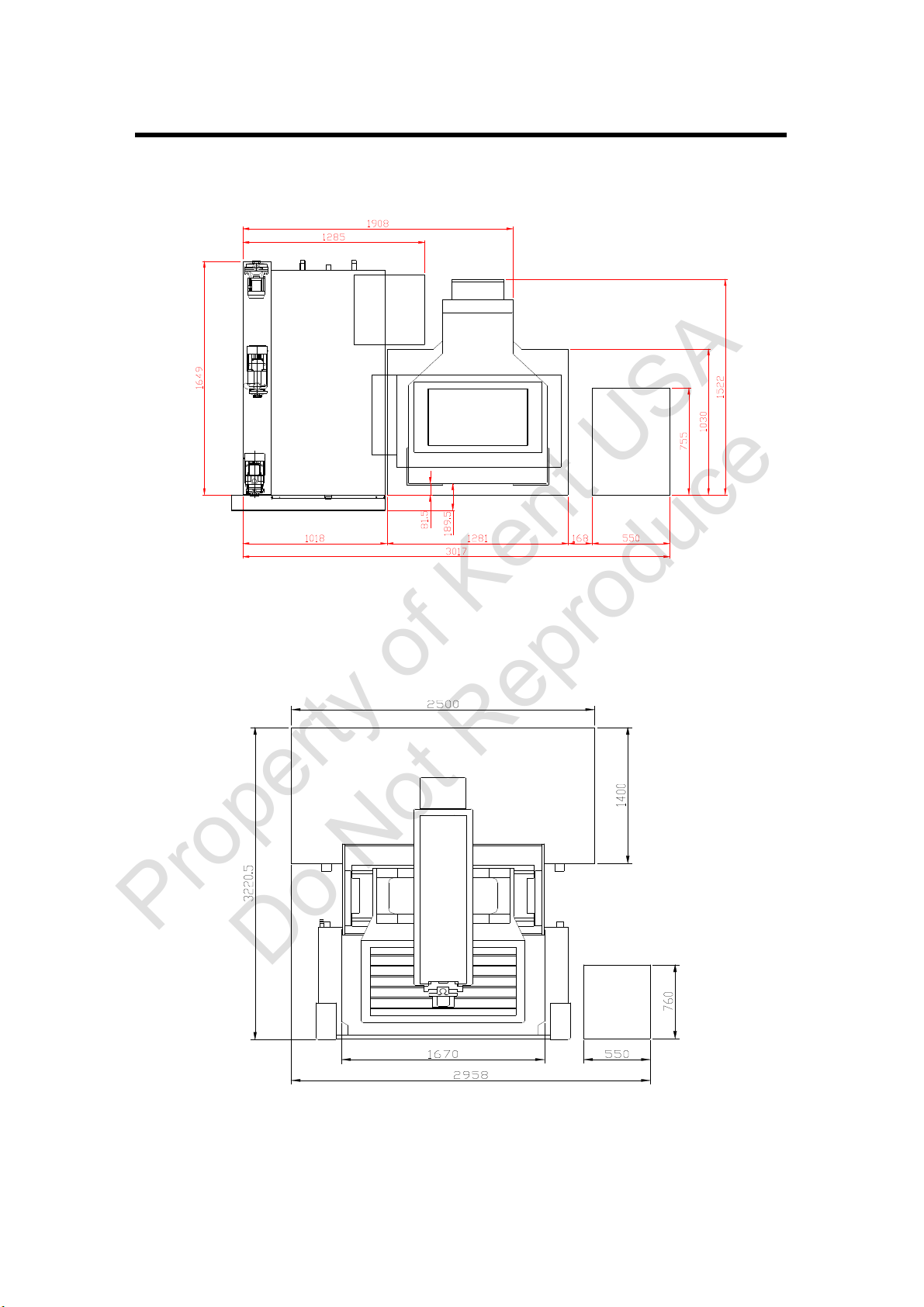

KEB-600LCNC (S.F) unit:mm

KEB-700LCNC Unit: mm

Oil tank

machine

Electric

control box

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2.Machine transportation & Installation

3

KEB-800LCNC Unit: mm

KEB-900LCNC Unit: mm

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2. Machine Transportation & Installation

- 4 -

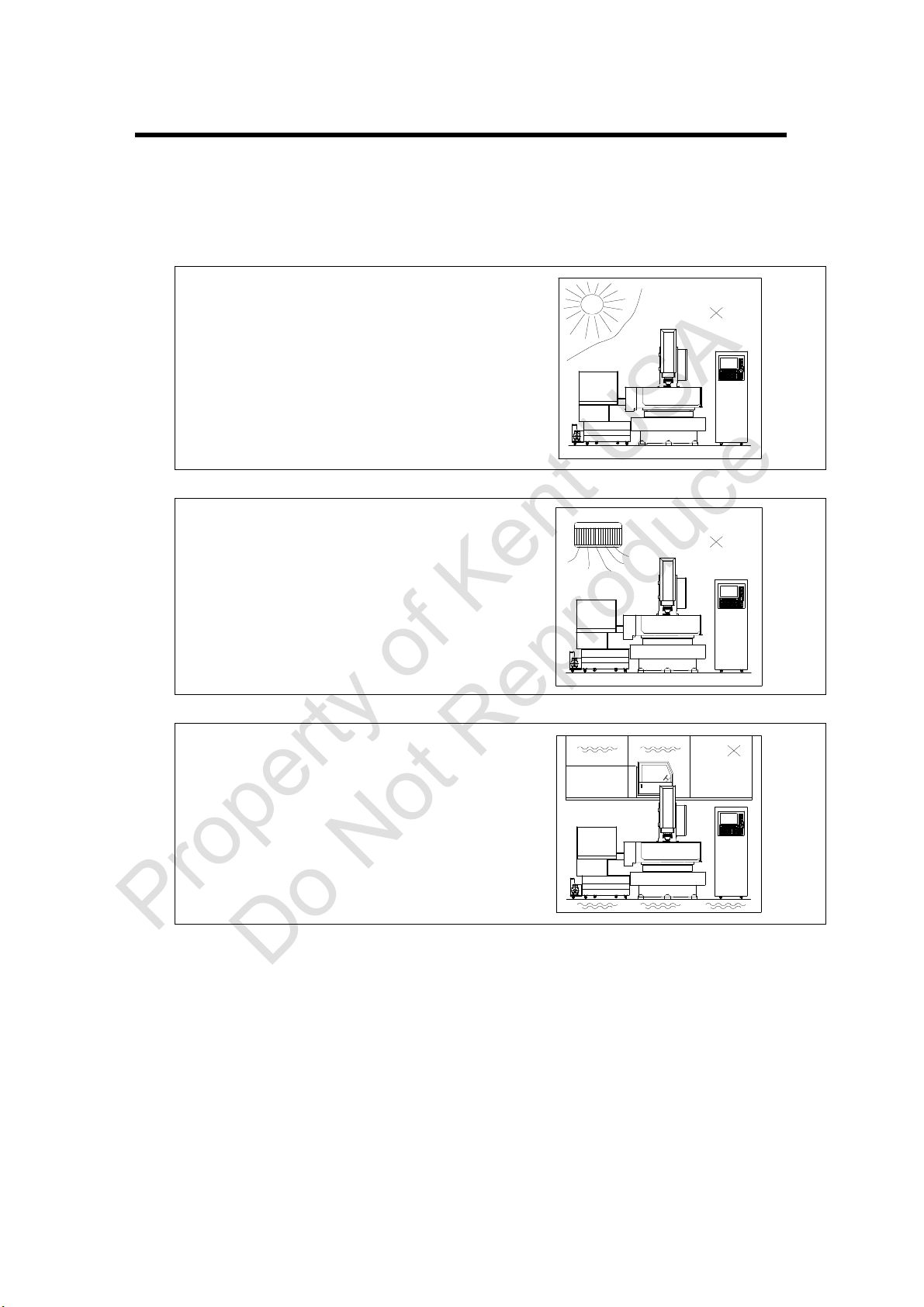

2.2 Installation site

(1)CNC EDM is a precision machine. Please carefully select

an installation site according to following points:

1. Install the machine at less dust

and bright place, but avoid being

exposed under direct sunlight.

2.

The machine must be installed at a

well-ventilated and temperature

regulated place (Suggested work

temperature to be 25℃). Avoid

air conditioner to blow air directly

to the machine.

3. The machine must be installed on

a no-vibration and solid ground.

4. The machine surroundings should

be reserved a sufficient space (at

least 300mm) for the convenience of

loading workpiece and machine

service.

5. The path where the machine will

pass should be safe and wide

enough.

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2. Machine Transportation & Installation

- 5 -

2.3 Transportation

Machine:

(1)Use only forklift to move the machine as following FIG. shown.

(2)KEB-600LCNC needs at least 2.5 Ton forklift.

(3)KEB-700LCNC needs at least 5 Ton forklift.

(4)KEB-800LCNC needs at least 10 Ton forklift.

(5)KEB-800LCNC needs at least 10 Ton forklift.

!Note

* Keep machine balanced during transportation. The

machine should avoid slanting.

* When the machine is lifted by forklift, the center of

gravity of the machine should be slightly backward.

* Before using the forklift, be careful with the

transportation path, and verify that the space is wide

enough for making a U-turn.

* Only qualified persons are allowed to operate the

forklift.

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2. Machine Transportation & Installation

- 6 -

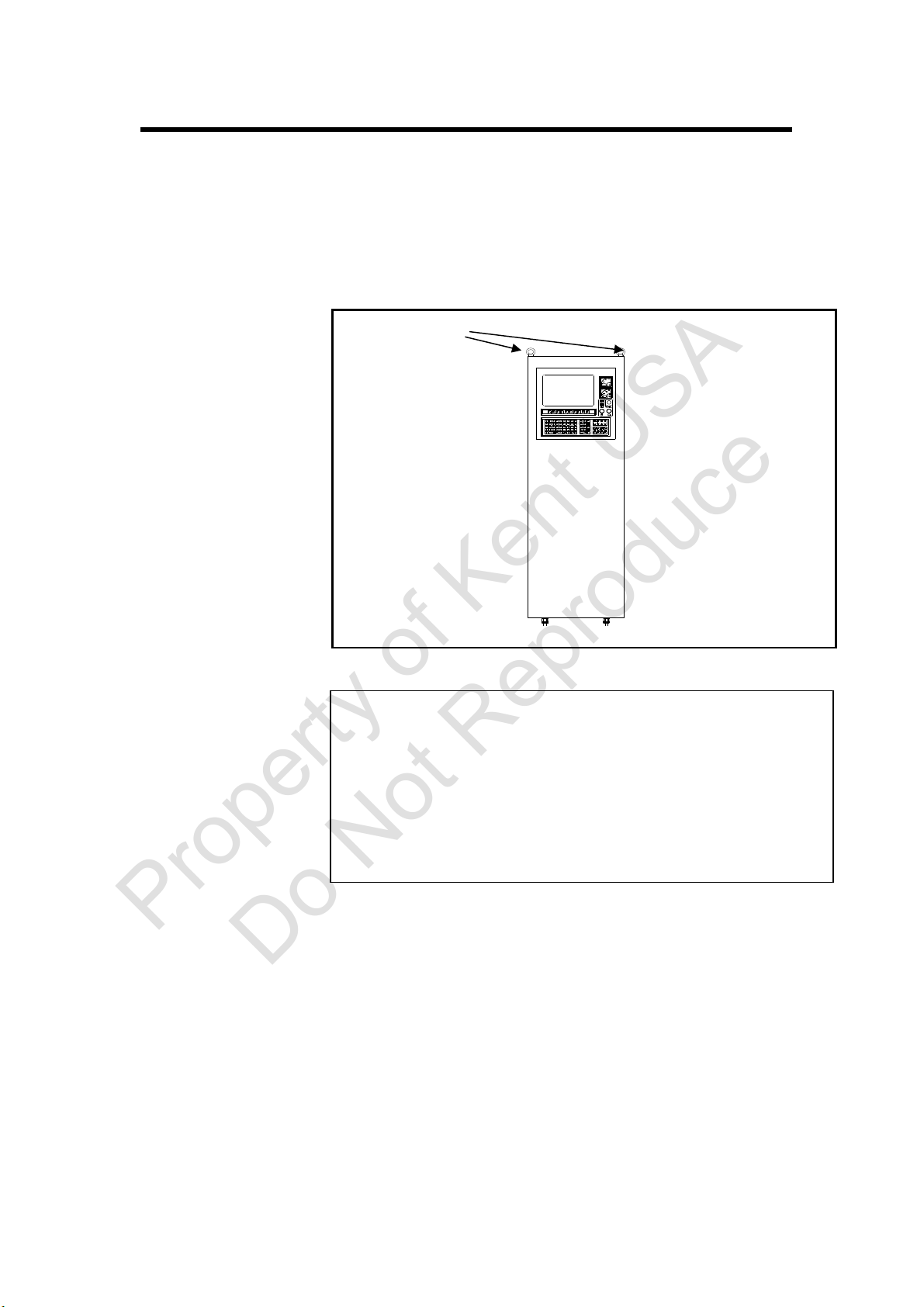

Power control box:

(1)Use a hoister to hook the power control box as following figure shown.

(The power control box has two hanging rings.)

(2)The power control box on the ground can be moved.

!Note

Transportation of work liquid tank

(1)Use a forklift to move it.

(2)When the work liquid tank is on the ground, you can use hands to push

the work liquid system.

Hanging ring

Hook the hang

rings to move

the power control

box.

* When the power control box is moved on the ground,

the ground should be even and without any obstacles.

* For pushing the power control box, there should be

one man before and behind the power control box so

as to avoid losing center of gravity, or the power control

box may overturn.

Property of Kent USA

Do Not Reproduce

KEB-CNC Opertation Manual

2. Machine Transportation & Installation

-7-

2.4 Machine installation

(1)Power supply and wire connection

1. It would be better to prepare a voltage stabilizer for the power required

by the electric control box. It is necessary to have a protective measure

for your machine before installation.

!Note If the voltage fluctuation in your area is over + 10%, it is

necessary to install a voltage stabilizer to protect the

controller, and ensure a normal function with the circuit

board. It is to prevent the machine from being damaged.

2 . The machine must be grounded. It is better that the operator stands on

a wooden stand to operate the machine.

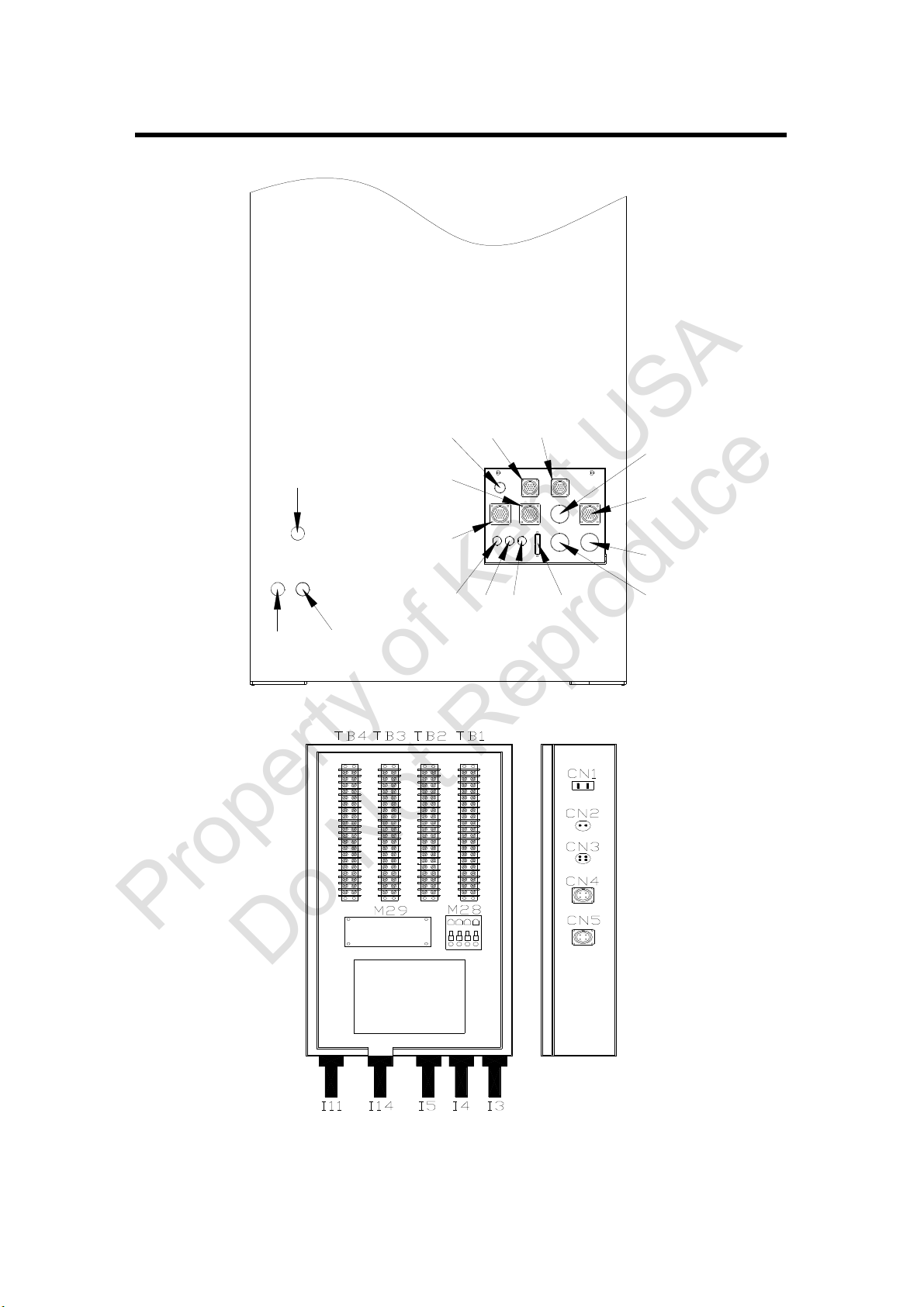

3. The wire connection of the machine is as following figure shown.

Please connect the electric control box and the wires according to the

instructions.

!Note Do not connect the auto fire extinguisher to the electric

control box in parallel so as to avoid error action on safety

functions.

Property of Kent USA

Do Not Reproduce

KEB-CNC Opertation Manual

2. Machine Transportation & Installation

-8-

I1

I2

I9

I4

I3

I6 I7 I8 I13

I11

I10 I12

I15

I5

I16

I14

Wire diagram of machine to electric control box

Property of Kent USA

Do Not Reproduce

KEB-CNC Opertation Manual

2. Machine Transportation & Installation

-9-

(2)Remove the red metal plates of X and Y axes

KEB-600L

Fixed plate of Y axis

Fixed plate of X axis

KEB-433

Fixed plate of Y axis Fixed plate of X axis

Property of Kent USA

Do Not Reproduce

KEB-CNC Opertation Manual

2. Machine Transportation & Installation

-10-

(3)Level the machine

1 . There are 5 level bolts under the adjusting base.

Use a wrench to turn the level bolts, and level the

machine.

2. Measure again and again till the machine is

practically leveled.

(4)Remove anti-rust oil

During the storage and transportation, some

components and the hand scraping surface of the

parts needs to be covered with one layer of

anti-rust oil. Before using the machine, it is

necessary to degrease them by kerosene, gasoline

or methyl benzene. After removing the anti-rust oil,

please feed following lubricant or same grade

lubricant to the machine.

SHELL TONNA 68

GULF GULF 59

Machine base

nut

Level bolt

Level block

Property of Kent USA

Do Not Reproduce

KEB-CNC Opertation Manual

2. Machine Transportation & Installation

-11-

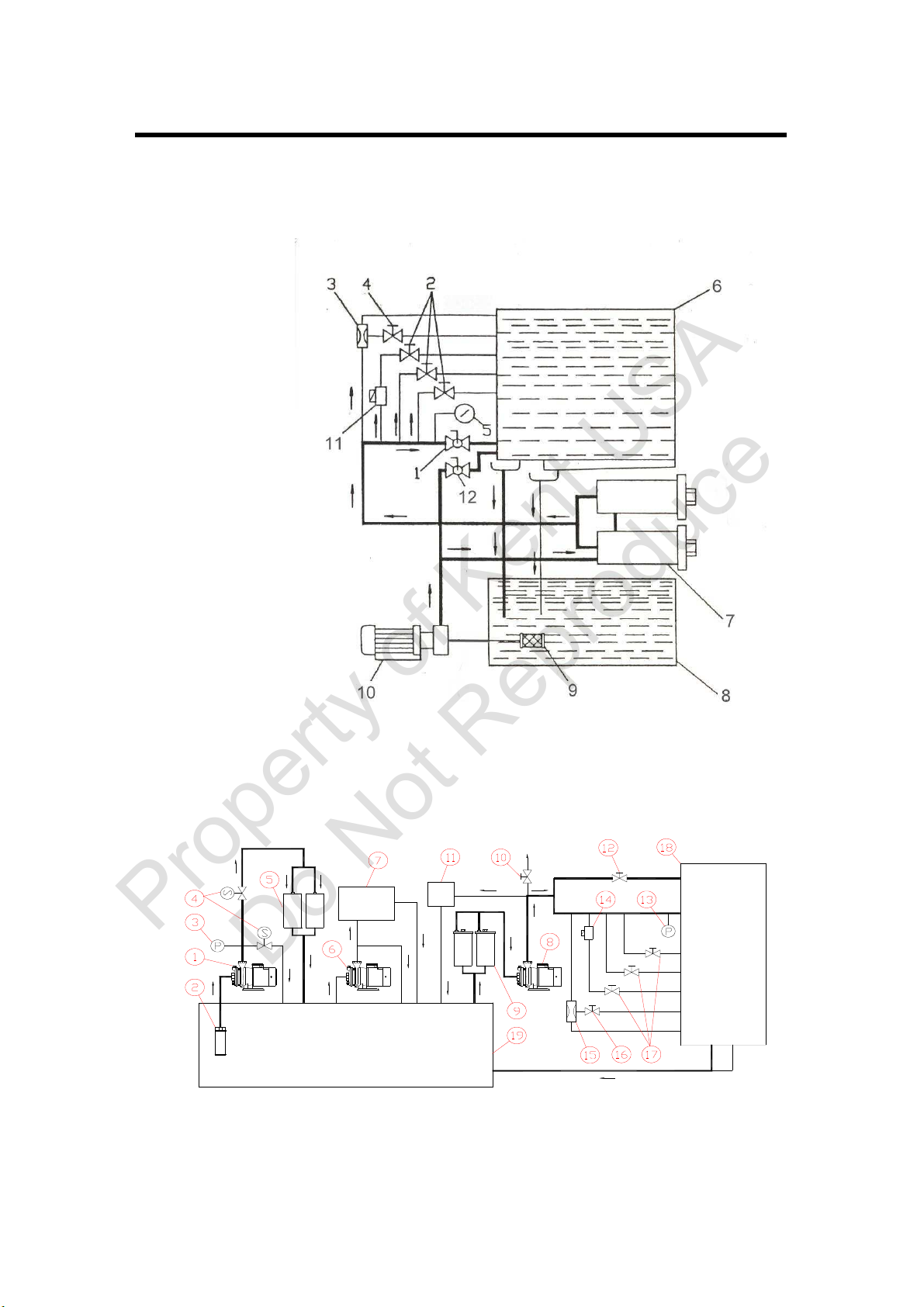

(5)Install pipes of oil tank

Connect the oil tank to the inlet of the oil trough, and fix the pipe.

01 oil filter valve

02 oil spray valve

03 oil sucker

04 oil sucking valve

05 built-in

pressure meter

06 oil trough

07 filter barrel

08 oil tank

09 filter net

10 oil pump

11 intermittent

oil spray

12 fast oil

feeding valve

Suitable models: KEB-600L、KEB433

Suitable models: KEB-600L(S.F.)

Oil tank

Oil trough

Property of Kent USA

Do Not Reproduce

KEB-CNC Opertation Manual

2. Machine Transportation & Installation

-12-

01 motor for filtering silicon powder 11 powder tester

02 small filter net 12 fast oil feeding valve

03 vertical pressure meter 13 built-in pressure meter

04 solenoid valve 14 intermittent oil spray

05 powder filter net 15 oil sucker

06 cooling motor 16 oil sucking valve

07 cooler 17 oil spray valve

08 motor for filtering metal powder 18 oil trough

09 metal powder filter barrel 19 oil tank

10 pressure valve for oil spray gun

(6)Check the door catch of oil trough

1. Before

feeding oil,

please check if

the door catch is

clasped. (For

the machine to

be exported, its

door catch is

loosened.) If the

door cannot be

clasped, please

use one 4mm

wrench to adjust

the tightness.

Suitable models: KEB-600L, KEB-433

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

2. Machine Transportation & Installation

- 13-

2.5 Check before start the machine

1. Check power

Before starting the machine, please verify if the input power agrees with the

rating power labeled on the electric control box.

2.Check the electric control box

If the machine arrived through a long transportation, please ask the

installation technician to open the front and the rear doors of the electric

control box, and check if any of the contact is loose.

3. Check the connecting wire

Verify if every wire is connected to correct position as labeled.

4. Verify the removal of the shipment blocks

There is one fixed block to lock X axis and Y axis respectively. It is to

prevent X axis and Y axis moving during transportation. Before you switch

on the power, please verify these blocks are removed.

5. Check if oil can enter every oil pipe of the oil feeder

6. Check the pipe circuit of work liquid

A: Close the two doors of the oil trough. Check if the door catch is clasped.

B: Check if the oil trough and the tube harness of the oil tank are tightened.

C: Fill oil to the oil tank and the pump. Close all the oil spray valves. Then,

you can switch on power.

D: Switch on power, and start the machine in order. After completing the

start procedure of the machine, press PUMP ON, and verify if the pump

rotates in arrowheaded direction.

E: Check if the pressure valve of the oil trough reaches 20 KGS (When

input 380V to motor, the oil trough reaches 30 KGS) . Please also check

if the filter barrel leaks oil.

F: Check the oil spray valve.

G: Check the oil sucking valve.

H: Check if the door of the oil trough leaks oil.

I: Check if the surroundings of the oil trough leaks oil.

Property of Kent USA

Do Not Reproduce

KEB-CNC Operation Manual

3. Safety Directive

-1- 1

3. Safety Directive

The work liquid used in EDM will sparkle and produce high temperature

during work. Therefore, following regulations must be strictly followed.

1. Safety Device and its installation

Do not remove or modify any of the safety devices without permission

when you operate the EDM.

(1)power : EDM should have an independent power supply. Do not

share a circuit breaker with other machines.

(2)Liquid level sensor: when the level of the work liquid is lower than

the setting, the machine will stop working immediately, and sends

out a warming.

(3)Fire prevention sensor: When fire alarm happens during work, the

machine will stop working immediately, and sends out a warming.

(4)Fire extinguisher : when the work liquid is on fire, the auto fire

extinguishing device will spray fire-extinguishing chemical

automatically.

(5)Temperature control switch ( limited to the machines with CE mark) :

Please set 50℃for the work liquid. If the temperature is over 50℃,

the machine will stop working immediately. 8

(6)The switch of oil trough door (limited to the machines with CE

mark): if the door of the oil trough is open, the machine cannot

work.

2. Environment

Be sure to clean the surroundings of the machine frequently

(1)Avoid harm to the operators

a. The work liquid is one kind of corrosive liquid. It will make human

skin allergic. Suggest the operators to wear work gloves, or

spread hand ointment. Suggest the operators to wear gloves, or

Spread hand care ointment.

b. The work process will produce harmful gas to operators. Please

install an exhaust pipe to exhaust the waste gas during the work.

(2)Avoid polluting environment

a. Avoid work liquid leak

b. Prepare a non-leaking floor.

Property of Kent USA

Do Not Reproduce

This manual suits for next models

2

Table of contents