SERVICE

MANUAL

©

1990-3

PRINTED

IN

JAPAN

B51-8050-00

(O)

1403

REVISED

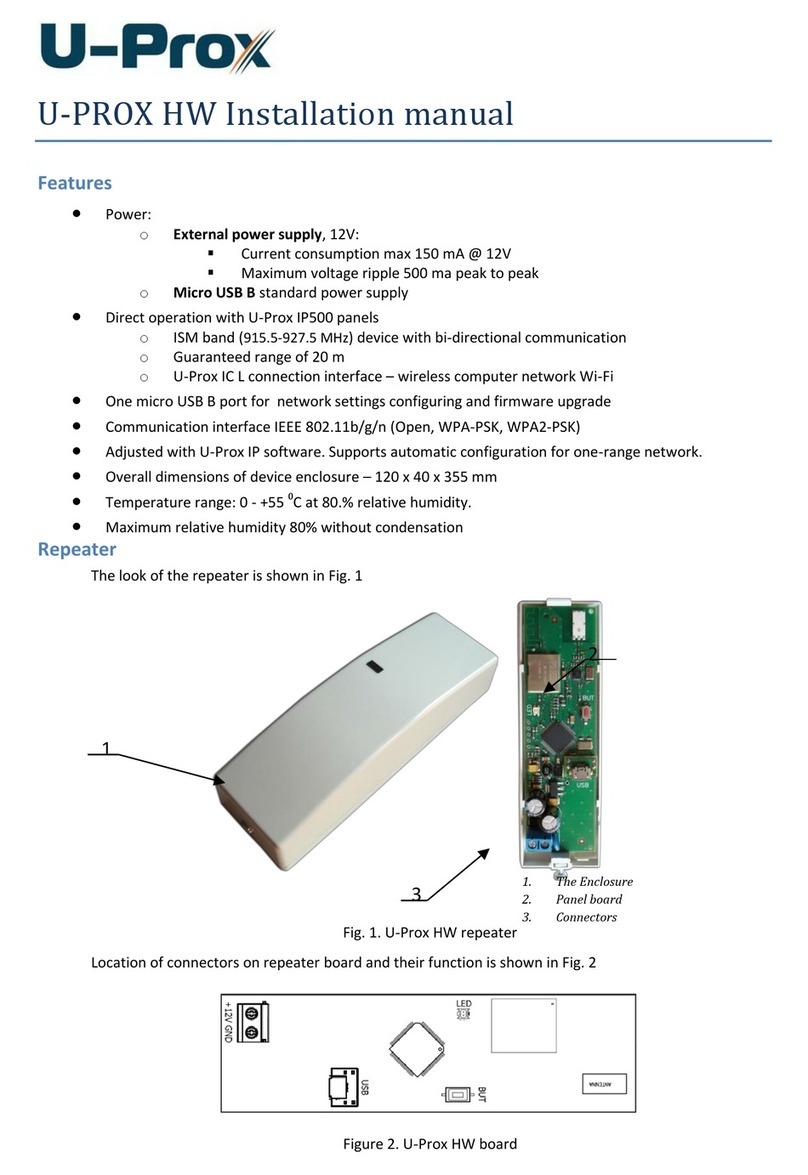

Panel

Case

(Upper)

Dressing

plate

Knob

(TAKE

OVER,

REPEAT,

MONI)

(A20-2666-11)}

(A01-1059-01)

(A21-1519-03)

(K29-3148-04)

x

3

Knob

(POWER)

Foot

Knob

(VOL,

SQL)

Dressing

plate

Rectangular

receptacle

(MIC)

(K29-31

46-04)

(J02-0049-14)

x

4

(K29-3147-03)

x

2

(A21-1520-03)

(E08-0673-05)

CONTENTS

GENERAL

.........ccccsceececeeesseesesscecescsencerceeeuserssseceeneestes

2

RX

VCO

:

Z2

(X58-3150-XX)

wesscseccecesseecnsenssrseesene

63

SYSTEM

SET-UP

.........:sscscessscstsrnssssccuseseserenseeseers

4

TX

VCO

:

Z5

(X58-B460-XX)

....eecreeceseersseessnsscereue

64

INSTALLATION

......0..cceccsssessesssensessensccescersssseneaeeeeeses

5

MIC

AMP

:

Z7

(X59-3210-10)

....scccssececesnsereseeen

-

65

CONVERSION

.........-cccsssesceeeetsessccevensssseceusvsseneesssssees

9

IF

:

ZB

(X59-3220-1O)

...

ee

eesecesssnssteteeeeseensneesneneetan

-

66

DISASSEMBLY

FOR

REPAIR

.............::sccsseessereees

11

BPF

/

VCA

:

Z9

(X59-3230-10)

...sccsesessrsrsesssereenn

-

67

BLOCK

DIAGRAM

............--:::scssccrsercessersetseeneecsenens

17

AVR

UNIT

(X43-3040-10)

oo...

ccseeesseseesssteesseeeeeene

-

68

CIRCUIT

DESCRIPTION

.............ceccssssesssersseeessereees

19

FINAL

UNIT

(X45-3250-XX)

...cssseccceeeeessecenstseeene

-

70

SEMICONDUCTOR

DATA

..........::cecccssscssesenteseseees

26

SIGNALING

UNIT

(X52-3140-10)

.....eceesstceesseren

-72

DESCRIPTION

OF

COMPONENTS

............scsceeees

31

DISPLAY

UNIT

(X54-3070-11)

.eecscccccccssreeneessenn

~

74

PARTS

LIST

........::cccescseeceescenseeresnnseneneceesscersscasenenses

33

TX-RX

UNIT

(X57-3270-XX)

oo

ecessessssseessceesesseneenn

-

78

DISASSEMBLY

.........ccscsssscccresenensessonnseusessconeresenses

53

SIGNALING

CIRCUIT

DIAGRAM

.................00008

-

83

PACKING

..........ccssssscssesseneescsesseccceeesssseosenancansrsseneses

55

SCHEMATIC

DIAGRAM

............ccssseesececssessenernennn

-

87

ADJUSTMENT

........:ccccccscsccorccessesusenscnscunsnrsesenezetsss

56

TERMINAL

FUNCTIONG.

.............:ccceeeeecesersencoeeens

~

95

PC

BOARD

VIEWS

/

CIRCUIT

DIAGRAMS

KMC-9

(BASE

MICROPHONE)

...........--cccsecsoeeetene

-

97

RX

PLL:

Z1,

TX

PLL

:

Z4

(X58-3120-10)

....sececees

62

SPECIFICATIONS.

...........csssscsseresessees

BACK

COVER