KEPCO P220 User manual

P220 Printer

User's Manual

990383 06/19/17

KESSLER-ELLIS PRODUCTS

10 Industrial Way East

Eatontown, NJ 07724

800-631-2165 • 732-649-7100

Fax: 732-649-7099

– Page 1 –

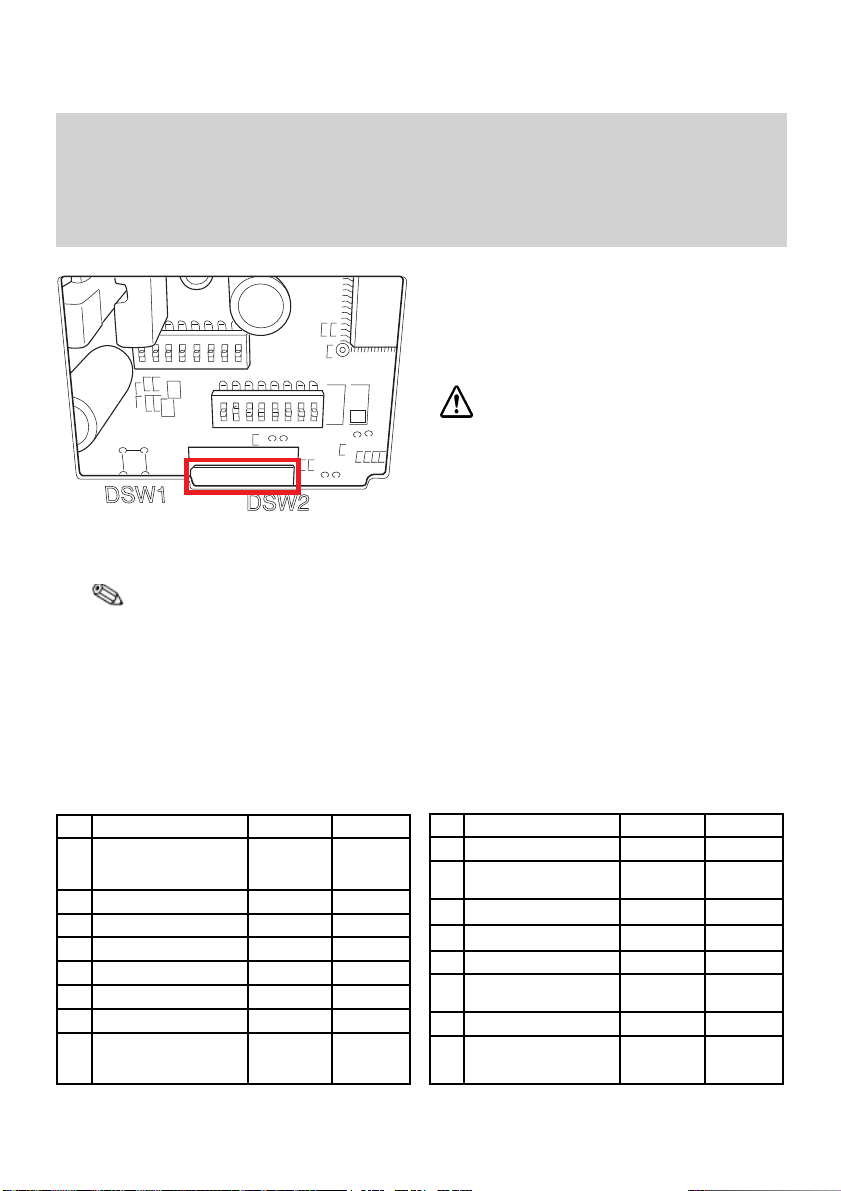

DIP Switch Settings

Look at the numbers and letters in the

area indicated in the illustration. If the last

letters are “US”, use the “US” tables below.

If the last letters are “STD”, use the “STD”

tables.

CAUTION:

Be sure to replace the DIP switch cover

before using the printer.

SW Function On Off

1 Printing mode Right side up

printing mode

Normal print-

ing mode

2 Receive buffer capacity 40 bytes 4 KB

3 Handshaking XON/XOFF DTR/DSR

4 Word length 7 bits 8 bits

5 Parity check Yes No

6 Parity selection Even Odd

7 Transmission speed 4800 bps 9600 bps

8BUSY condition Receive buffer

full

Receive

buffer full or

Ofine

US

Serial (DIP Switch 1) Serial (DIP Switch 2)

*: If you set DIP Switch 1-1 to On (Right side up printing mode), make sure to set DIP Switch 1-2 to Off (Receive buffer

capacity: 4 KB).

SW Function On Off

1 Print column 42/35 40/33

2 For internal use only

(autocutter)

Enabled Disabled

3Pin 6 reset signal Used Not used

4Pin 25 reset signal Used Not used

5Undened - -

6 For internal use only

(ash memory rewriting)

Enabled Disabled

7Undened - -

8 Serial interface selection Memory

switch

DIP switch

Serial Interface Settings

Note:

The printer interface settings are set at the factory for communication with KEP Flow

Computers. This provides a "plug-and-play" scenario in which neither the printer nor

ow computer serial interface settings need to be set in order for them to communicate.

If you are connecting the printer to a different device, you may need to change the serial

interface settings for proper communication. Check the required settings of your device

and use the Serial Interface DIP Switch Tables below to change the settings.

Dip Switch Location

1. Locate DIP switch cover on bottom of

printer.

2. Remove screw securing DIP switch cover.

3. Remove DIP Switch cover to access

switches.

DIP Switch Tables

4. Set Switches to desired position.

5. Reinstall cover and reinstall screw snugly.

6. Cycle the power for the new DIP switch

settings to take eect.

– Page 2 –

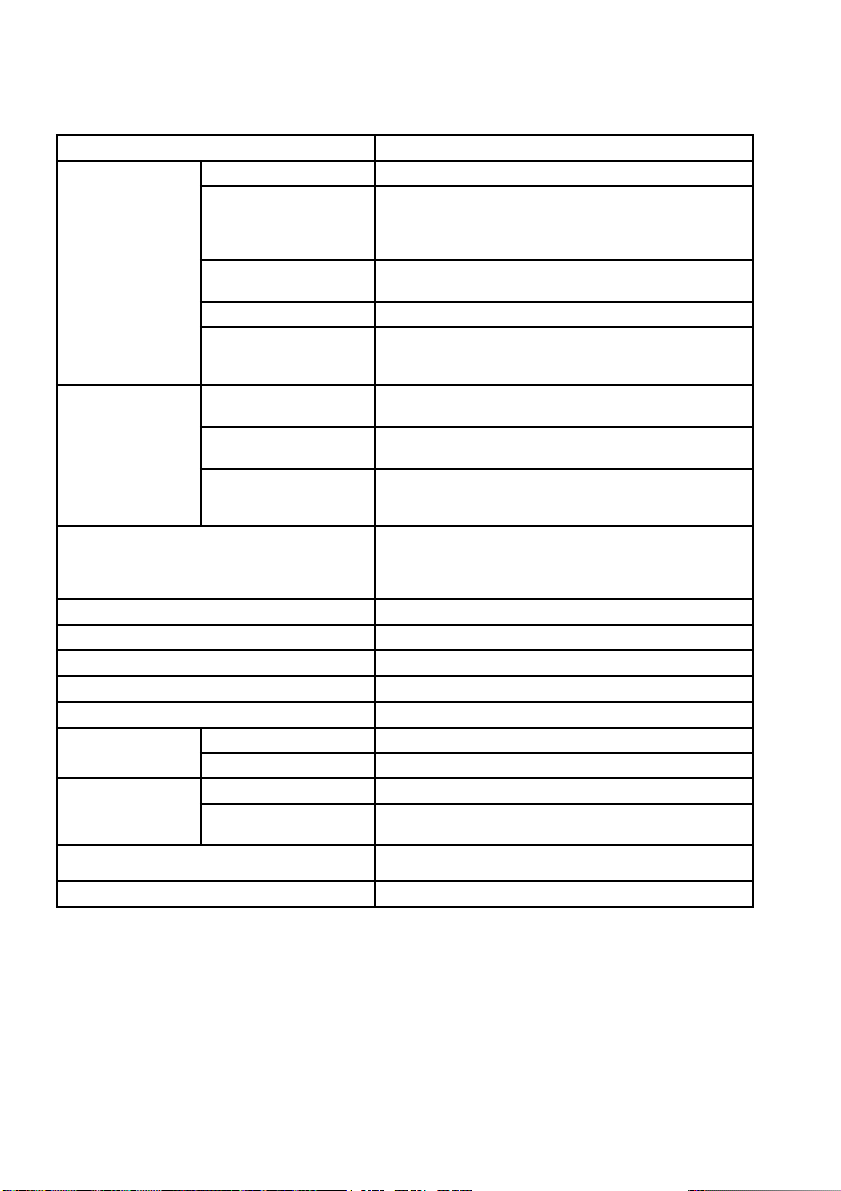

SW Function On Off

1 Data receive error Ignored Prints “?”

2 Receive buffer capacity 40 bytes 4 KB

3 Handshaking XON/XOFF DTR/DSR

4 Word length 7 bits 8 bits

5 Parity check Yes No

6 Parity selection Even Odd

7 Transmission speed 4800 bps 9600 bps

8BUSY condition Receive buffer

full

Receive buf-

fer full or

Ofine

STD

Serial (DIP Switch 1) Serial (DIP Switch 2)

SW Function On Off

1 Print column 42/35 40/33

2For internal use only

(autocutter) Enabled Disabled

3Undened - -

4 Serial interface selection Memory switch DIP switch

5Undened - -

6For internal use only

(ash memory rewriting)

Enabled Disabled

7 Pin 6 reset signal Used Not used

8 Pin 25 reset signal Used Not used

25 pin D-SUB

female connector

on printer

12345

6789

9 pin D-SUB female

connector at KEP

ow computer (FC)

Printer Pin

Number

Printer

Pin Name

2 TXD

3 RXD

6 DSR

7 Ground

20 DTR

5 CTS

4RTS

FC Pin

Number

FC Pin

Name

1 CTS

2 TXD

3 RXD

5 Ground

7RTS

Serial Port Connectors

Panel Mount ST2 Series Wall Mount

25 pin D-SUB

female connector

on printer

6 pin terminal block

connector at KEP

ow computer (FC)

Printer Pin

Number

Printer

Pin Name

2 TXD

3 RXD

6 DSR

7 Ground

20 DTR

5 CTS

4RTS

FC Pin

Number

FC Pin

Name

1 TXD

2 RXD

3 Ground

4 Bias

5 CTS

6MP (+8V)

Typical Cable Connections

DB25 DB9

2 1

3 2

4 3

7 5

DB25 TB

2 1

3 2

4 3

7 5

– Page 3 –

Serial Port Connectors

MS716

25 pin D-SUB

female connector

on printer

6 pin terminal block

connector at KEP

ow computer (FC)

Printer Pin

Number

Printer

Pin Name

2 TXD

3 RXD

6 DSR

7 Ground

20 DTR

5 CTS

4RTS

FC Pin

Number

FC Pin

Name

1 TXD

2 RXD

3 Ground

4 MP

5 CTS

6 Do Not

Use

MS748

25 pin D-SUB

female connector

on printer

6 pin terminal block

connector at KEP

ow computer (FC)

Printer Pin

Number

Printer

Pin Name

2 TXD

3 RXD

6 DSR

7 Ground

20 DTR

5 CTS

4RTS

FC Pin

Number

FC Pin

Name

1 TXD

2 RXD

3 Ground

4 Bias

5 CTS

6MP (+8V)

ST1 Series Wall Mount

25 pin D-SUB

female connector

on printer

6 pin terminal block

connector at KEP

ow computer (FC)

Printer Pin

Number

Printer

Pin Name

2 TXD

3 RXD

6 DSR

7 Ground

20 DTR

5 CTS

4RTS

FC Pin

Number

FC Pin

Name

1 TXD

2 RXD

3 Ground

4 MP

5 CTS

6 Do Not

Use

Typical Cable Connections

DB25 TB

2 1

3 2

4 3

7 5

– Page 4 –

P220 Specications

dpi: dots per 25.4 mm (dots per inch); lps: lines per second; lpi: lines per 25.4 mm (lines per inch)

*1: Be sure to use a safety-standards-applied power source that meets the following specications.

Rated output: 24 V/2.0 A or more, Maximum output: 240 VA or less

Printing method 9-pin serial impact dot matrix method

Print font Font (standard) Font A: 7 × 9, Font B: 9 × 9

Column capacity

(columns)

7 × 9/9 × 9:

76 mm: 40/33

69.5 mm: 36/30

57.5 mm: 30/25

Character size (W ×H)

(standard)

1.2 × 3.1 mm/1.6 × 3.1 mm (not including horizontal spacing)

Character set 95 Alphanumeric, 48 International,128 × 12 Graphic

Characters per inch

(standard)

(3 half dot spacing)

Font A (7 × 9): 16 cpi, Font B (9 × 9): 13.3 cpi

Paper Dimensions (mm) 57.5 ±0.5, 69.5 ±0.5,

76 ±0.5

Normal paper (mm) Thickness: 0.06~0.085 (1 sheet)

Pressure-sensetive paper Thickness: 0.05~0.08 (1 sheet), total thickness must be 0.14

mm or less.

Number of copies: Original 1 sheet + one copy sheet

Ribbon cassettes ERC-38 (B) Black life: 3,000,000 characters

ERC-38 (B/R) Black/Red life: Black 1,500,000/Red

750,000 characters

Life based on continuous printing at 25°C {77°F}

Printing speed (Paper width 76 mm) 4.7 lps (40 columns, 16 cpi)

Interface RS-232 or IEEE 1284

Receive buffer 4 KB or 40 bytes

Power supply*1 24 VDC ±7%

Cash drawer function 2drives

Temperature Operating 0~50°C

Storage –10~50°C, without paper and ribbon cassette

Humidity Operating 10~90%, must be no condensation

Storage 10~90%, must be no condensation, without paper and ribbon

cassette

Overall dimensions (mm) 160 × 248 × 138.5 (W × D × H)

Mass (approx.) 2.3 kg

– Page 5 –

Important Safety Information

This section presents important information intended to ensure safe

and eective use of this product. Read this section carefully and store

it in an accessible location.

Key to Symbols

The symbols in this manual are identied by their level of importance,

as dened below. Read the following carefully before handling the

product.

WARNING:

Warnings must be followed carefully to avoid serious bodily injury.

CAUTION:

Cautions must be observed to avoid minor injury to yourself or damage to your

equipment.

Safety Precautions

WARNING:

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise. Continued use may lead to re. Immediately unplug the equip-

ment and contact your dealer or a service center for advice.

Never attempt to repair this product yourself. Improper repair work can be dan-

gerous.

Never disassemble or modify this product. Tampering with this product may

result in injury or re.

Be sure to use the specied power source. Connection to an improper power

source may cause re.

Do not allow foreign matter to fall into the equipment. Penetration by foreign

objects may lead to re.

If water or other liquid spills into this equipment, do not continue to use it. Con-

tinued use may lead to re. Unplug the power cord immediately and contact your

dealer or a service center for advice.

If you open the DIP switch cover, be sure to close the cover and tighten the screw

after adjusting the DIP switch. Using this product with the cover open may cause

re or electric shock.

Do not use aerosol sprayers containing ammable gas inside or around this

product. Doing so may cause re.

– Page 6 –

CAUTION:

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage and burning. Be sure to set

this equipment on a rm, stable, horizontal surface. Product may break or cause

injury if it falls.

Do not use in locations subject to high humidity or dust levels. Excessive humid-

ity and dust may cause equipment damage or re.

Do not place heavy objects on top of this product. Never stand or lean on this

product. Equipment may fall or collapse, causing breakage and possible injury.

Take care not to injure your ngers on the manual cutter

• When you remove printed paper

• When you perform other operations such as loading/replacing roll paper

To ensure safety, unplug this product before leaving it unused for an extended

period.

Before moving the product, unplug it and unplug all cables connected to it.

Safety Label

The caution labels on the product indicate the following precautions.

WARNING:

Do not connect a telephone line to the drawer kick out connector; other-

wise, the printer and the telephone line may be damaged.

CAUTION:

During printing or after printing, the print head can be very hot.

Notes on Usage

❏Do not install the printer in a dusty place.

❏Protect the printer from impact.

❏Cords or other foreign objects must not be caught on the printer.

❏Do not apply excessive force to the printer case.

❏ Do not place food or beverages such as coee on the case of the

printer.

Notes on Installation

❏When using the printer, be sure that the printer is installed hori-

zontally.

– Page 7 –

❏Wall Mount option is available, you can hang it on a wall, using

the optional hanging bracket set, P220WMB.

Note:

To hang the printer on a wall, see Appendix A at end of this manual.

Notes on Connecting the Power Supply Unit

Be sure to use the correct power supply unit as listed below:

Note:

The “AC adapter, C,” which is packed with the alphanumeric model, cannot

be used with the multilingual* model. Be sure to use the “PS-180” with the

multilingual* model. If the “AC adapter, C,” packed with the alphanumeric

model, is connected to the multilingual* model by mistake, the printer might

not operate correctly. For example, printing might stop before all the lines are

printed or the printer might print the same line repeatedly.

*Multilingual means the printer model that can print any one of the following: Japanese Kanji, Simplied

Chinese, Traditional Chinese, Thai characters, or Korean characters.

Purpose of This Manual

This manual provides information to operators of the P220 to describe

basic operations to enable safe and correct use of the printer.

Restriction of Use

When this product is used for applications requiring high reliability/

safety, such as transportation devices related to aviation, rail, marine,

automotive, etc.; disaster prevention devices; various safety devices,

etc.; or functional/precision devices, etc.; you should use this product

only after giving consideration to including fail-safes and redundan-

cies into your design to maintain safety and total system reliability.

Because this product was not intended for use in applications requir-

ing extremely high reliability/safety, such as aerospace equipment,

main communication equipment, nuclear power control equipment,

or medical equipment related to direct medical care, etc., please make

your own judgment on this product’s suitability after a full evaluation.

P220 alphanumeric model P220 multilingual* model

“AC adapter, C” (packed with the alphanumeric model)

or “PS-180” (option)

“PS-180” (packed with the multilingual* model)

– Page 8 –

Unpacking

The following items are included for the standard specication printer. If any

item is damaged, contact your dealer.

❏Printer

❏Roll paper

❏Exclusive ribbon cassette [ERC-38]

❏AC adapter (May not be included with the printer.)

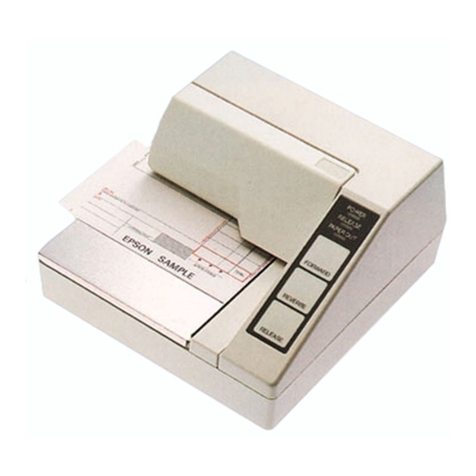

Control Panel (LEDs and Buttons)

See illustration B.

LEDs

POWER (POWER)

Lights when the power is on and is o when the power is o.

ERROR (ERROR)

Lights when the printer is oine (when the roll paper is at the end, or

the roll paper cover is open). O when the printer operates correctly.

Flashes when an error occurs. (See the Troubleshooting section.)

PAPER OUT (PAPER OUT)

Lights when roll paper is out or nearly out.

Buttons

FEED (FEED)

FEED (FEED) feeds the roll paper.

Note:

Paper cannot be fed by using this button when a paper out is detected.

A B

1

3 4 2

1. Roll paper

cover

2. Ribbon cassette

cover

3. Control panel

4. Power supply

switch

– Page 9 –

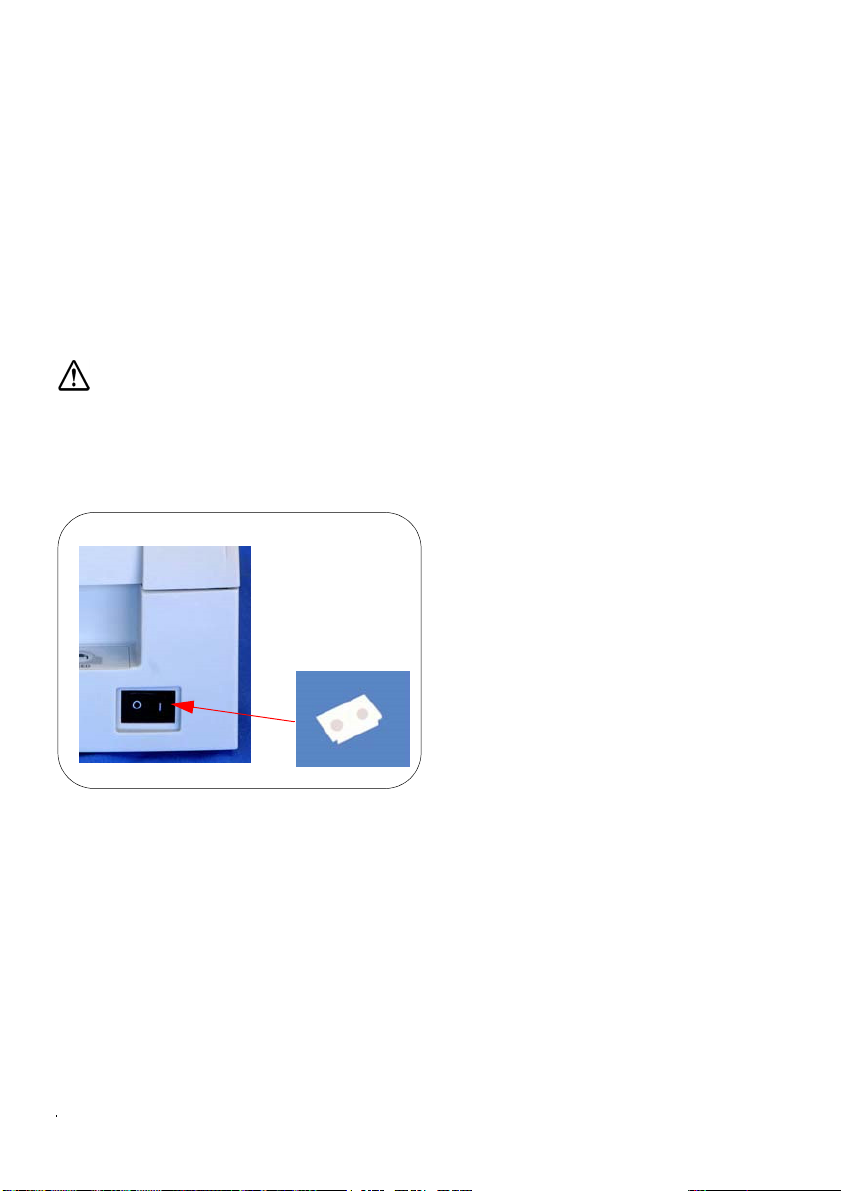

Power Supply Switch and Power Supply Switch Cover

The power supply switch is on the front of the printer. Press the power supply

switch to turn on the printer.

Power Supply Switch Cover

You can use the enclosed power supply switch cover to make sure that the

power supply switch is not accidentally pressed. Just press the cover into

place to install it. If you need to turn the power supply switch on or o with

the cover attached, you can insert a thin tool into one of the holes in the cover

to operate the switch. See illustration C.

WARNING:

If an accident occurs when the power supply switch cover is attached, immediately un-

plug the power supply cable to avoid re.

If you are going to store the printer or leave it unused for a long time, turn it

o using the power supply switch on the printer.

C

– Page 10 –

Inserting and Replacing the Ribbon Cassette

CAUTION:

The print head becomes very hot during printing. Allow it to cool before you replace the

ribbon cassette.

CAUTION:

Never turn the ribbon cassette’s feed knob in the opposite direction of the arrow marked

on the cassette; otherwise the ribbon cassette may be damaged.

Note:

1. Open the ribbon cassette cover by using the tabs on the sides of the cover,

as shown in illustration D.

2. Turn the knob two or three times in the direction of the arrow, as shown in

illustration E.

3. Insert the ribbon in the position shown in illustration F and push

the ribbon cassette down until it clicks.

Note:

Make sure the ribbon is installed between the print head and the platen without wrin-

kles or creases.

DE

F 4. Again turn the ribbon cassette’s knob

2 or 3 times in the direction

of the arrow and close the ribbon cas-

sette cover.

CAUTION:

Be careful not to touch the print head with your

ngers when turning the ribbon cassette knob

because the print head is hot and you might be

burned.

When you replace the ribbon cassette, lift the

left side of the ribbon cassette rst; then lift

the whole ribbon cassette.

– Page 11 –

Inserting Roll Paper

CAUTION:

Be sure to use roll paper that meets the specications.

Be sure not to touch the manual cutter. Otherwise your ngers might be injured.

1. Using scissors, cut the leading edge of the roll paper, as shown in illustra-

tion G.

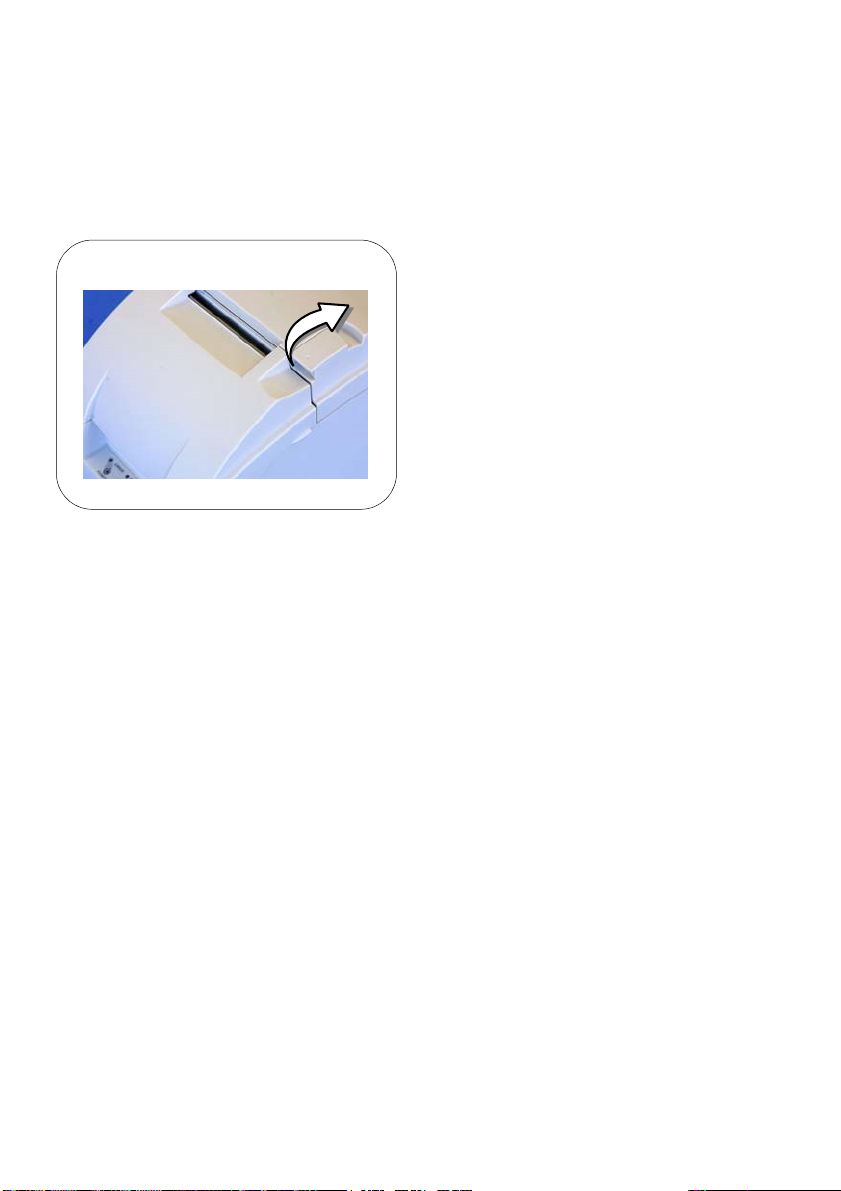

2. Turn on the printer and open the roll paper cover by using the tab, as

shown in illustration H.

3. Insert the roll paper, as shown in illustration J.

Note:

Note the direction the paper comes o the roll, as shown in the illustration G.

When using 2-ply roll paper, be sure that the top and bottom sheets are aligned at the

paper exit. See illustration G-a.

5. Pull out a small amount of roll paper and close the roll paper cover; then

tear o the paper with the manual cutter.

G-a

H

G

Note:

Do not open the roll paper cover during printing or paper feeding.

When using the printer, be sure to cut the roll paper with the manual cutter after

paper feeding is complete.

J

– Page 12 –

Replacing Roll Paper

1. Open the roll paper cover by using the tab, as shown in illustration H.

2. Remove the used roll paper core.

3. Insert new roll paper. See the section “Inserting Roll Paper”.

H

– Page 13 –

ERROR (ERROR) LED is ashing or lit

❏The print head temperature may be too high or low. Wait until the

print head cools or warms and the printer resumes printing auto-

matically.

❏Make sure that the roll paper cover is properly closed.

❏A paper jam has occurred. To remove the jammed paper, see the

instructions below.

❏ Turn o the power, wait several seconds, and then turn it on again.

If the error remains, contact your supervisor or a qualied service

person.

Removing jammed paper

CAUTION:

The print head becomes very hot during printing. Allow it to cool before you

reach into the printer.

1. Open the roll paper cover by using the tab, as shown in

illustration H. (Page 11)

2. Remove the jammed paper.

3. Re-insert the roll paper and close the roll paper cover.

*Multilingual means the printer model that can print any one of the following: Japanese Kanji, Simplied

Chinese, Traditional Chinese, Thai characters, or Korean characters.

No lights on the control panel

Check the power supply cable connections and the power outlet.

The power supply unit that can be used with the

P220 alphanumeric model

The power supply unit that can be used with the

P220 multilingual* model

“AC adapter, C” (packed with the alphanumeric model)

or “PS-180” (option)

“PS-180” (packed with the multilingual* model)

Troubleshooting

Printing stops before all the lines are printed or the printer prints the same line

repeatedly

If the correct power supply unit is not used, the printer cannot operate cor-

rectly. Make sure the correct power supply unit is connected to the printer,

referring to the table below:

– Page 14 –

Ordering Information:

EXAMPLE P220 N

Series

P220 Impact Receipt Printer

Options

N = NEMA 4X Wall Mount Enclosure with sub-panel

& duplex outlet

Accessories

P220WMB = Wall Mount Bracket for P220 Printer

P2CA25M9ML6 = 6’ Serial Cable for SUPERtrol I, SUPERtrol ILE,

LEVELtrol II, SUPERtrol II

P2CA25MFLL6 = 6’ Serial Cable for MS716 or any Flow Computer

with RS232 terminal block

P220PR-1P = Paper Roll for P220 Printer; Single-ply Impact 3"

width x 165' length, Single roll.

P220PR-2P = Paper Roll for P220 Printer; Two-ply Impact, 3"

width x 100' length. 1st copy is white, 2nd copy is

yellow. Single roll.

P220INK-B = Black Ink Fabric Ribbon

PC12-24DC = Power Converter 12VDC input, 24VDC output

Warranty:

Two-year limited warranty in the U.S. and Canada

– Page 15 –

1

2

4

3

4 1

3

2

1

2

4

3

4 1

3

2

Appendix A

How to Install the Printer on a Wall with the P220WMB

P220WMB is a option for the P220 printer, with it you can install a P220 on a wall. This section

describes how to install wall hanging P220.

A.1 The Procedure

A.1.1 Precautions

❏Static electricity may cause cut paper to adhere to the printer case.

(This static electricity will not aect the operation of the printer.)

A.1.2 Unpacking

Open the package and conrm that it contains all of the parts listed in the illustration. If any

parts are missing or damaged, please contact your dealer for assistance.

wall-mount (note: screws for

wall-mount not included; see the

installation section.) brackets (2 pieces)

screws for brackets (3×12)

(4 pieces)

roll paper holder for

hanging bracket

cam

control panel sheets

Please attach the appropriate sheet.

screws (3×10) screws (3×6) (5 pieces) Note:

4 of the screws are used for

attaching the brackets

Depending on the conditions during storage and shipping, some rust may form around the

edges of the wall-mount or brackets. This may be removed with sandpaper.

– Page 16 –

A

84mm

48mm

A.1.3 Installation

Before installation, be sure that the printer and all equipment connected to the printer is turned

o. Detach all cables from the body of the printer.

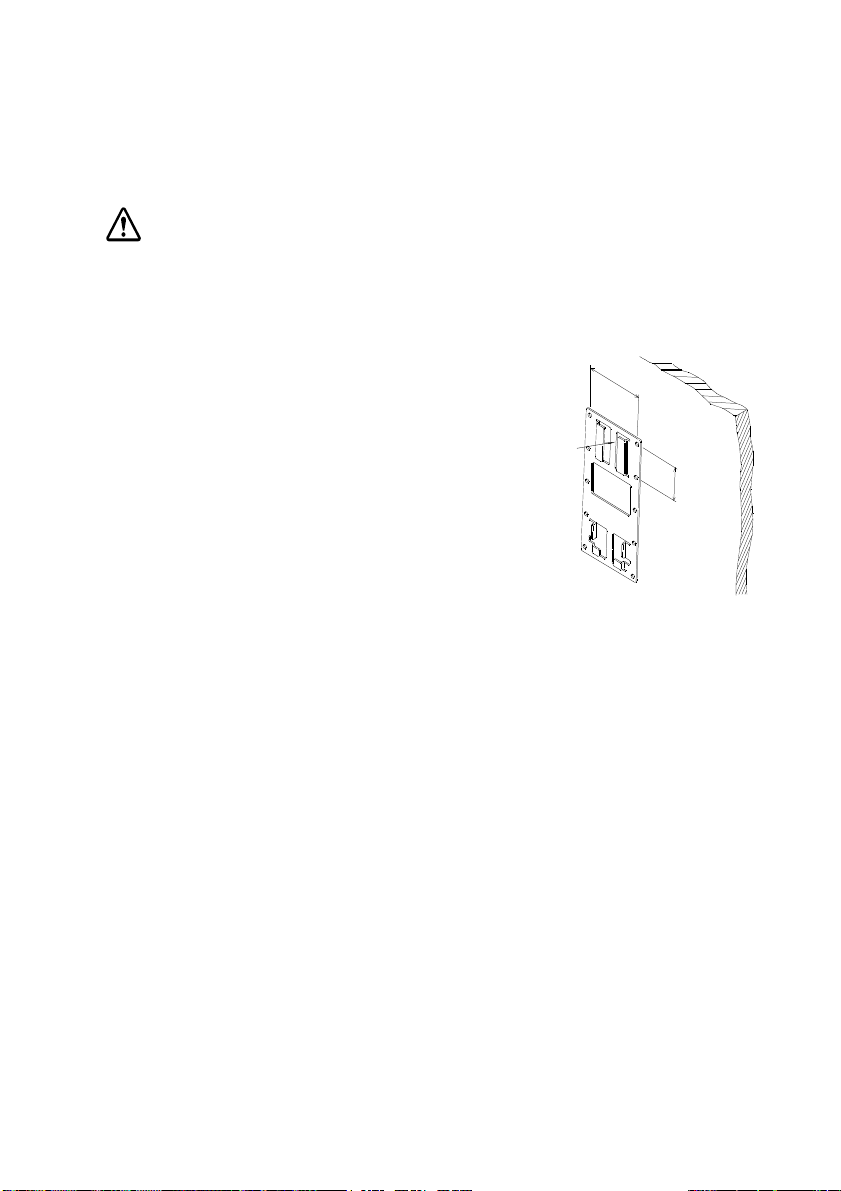

A.1.3.1 Installing the wall-mount

CAUTION:

The weight of the printer is approx. 2.3 kg. In order to insure that the wall-mount can properly support

the weight of the printer, please secure it with screws appropriate to the type of wall the wall-mount is

installed on. A screw with 4 mm diameter and length of 12 mm or more is recommended. The thickness of

the wall should be 10 mm or more.

Be sure to fasten the wall-mount securely to the wall with a screw in each of the ten holes.

Before attaching the wall-mount, make sure enough space remains

around the printer.

Make sure that there is enough space for opening the printer cover.

Attach the wall-mount to the wall in the position illustrated to the right

(with the area marked A at the top), and fasten securely with ten screws.

These screws are not included; please use screws appropriate to the type

of wall being used.

A.1.4 Afxing the operation panel sheet

When you mount the printer on the wall, the operation panel on the printer will be upside

down. Therefore, operation panel sheets in the correct direction for wall mounting have been

enclosed.

Align the FEED switch mark on the operation panel sheet with the FEED switch mark on the

printer operation panel and ax the operation panel sheet to the printer.

A.1.5 Changing the roll-paper detector position

Two types of screws are used with the P220WMB: 3×6 and 3×10. The longest screw (3×12) will

not be used.

1. Open the roll paper cover.

For a model that does not have a roll-paper near-end detector and does not need a change in

paper width, jump to step 7. For a model that does not have a roll-paper near-end detector

and needs a change in paper width, jump to step 3

– Page 17 –

cable

2. Loosen the detector adjustment screw a little bit by using a tool such as a coin and then

loosen the screw gently by hand as until it stops. It must not be removed completely.

detector ad-

justment screw

3. Remove the two screws of the roll paper guide.

roll paper

guide

For a model that does not have a roll-paper near-end detector , jump to step 6.

4. Rotate the detector lever on the roll paper guide to change its direction.

Note:

After the direction of the detector lever is changed, be sure that the cable is connected to the connector

rmly.

detector lever

5. Tighten the detector adjustment screw.

6. Align the hole on the roll paper guide with the hole on the roll paper holder to match your

roll paper width and then tighten the screw (3×10).

Note:

You will not use one of the two screws that have been removed when the roll paper guide is removed.

Please store it as an extra screw in case you need it.

– Page 18 –

76 mm 70 mm 58 mm

holder

dowel

hole

roll paper

guide

roll paper

7. Align the hole on the roll paper holder for hanging bracket with the dowel on the roll paper

guide. (For a model that needs a change of paper width, the hole to be used will be dierent

to match your roll paper width.)

Putting the screw (3×6) in the hole on the roll paper holder for hanging bracket makes it

easier for you to tighten the screw in the next step.

76 mm 70 mm 58 mm

roll paper holder for

hanging bracket

8. Tighten the screw (3×6) to x the roll paper holder for hanging bracket and the base frame.

Table of contents

Other KEPCO Printer manuals