CONTENTS

Section

Page

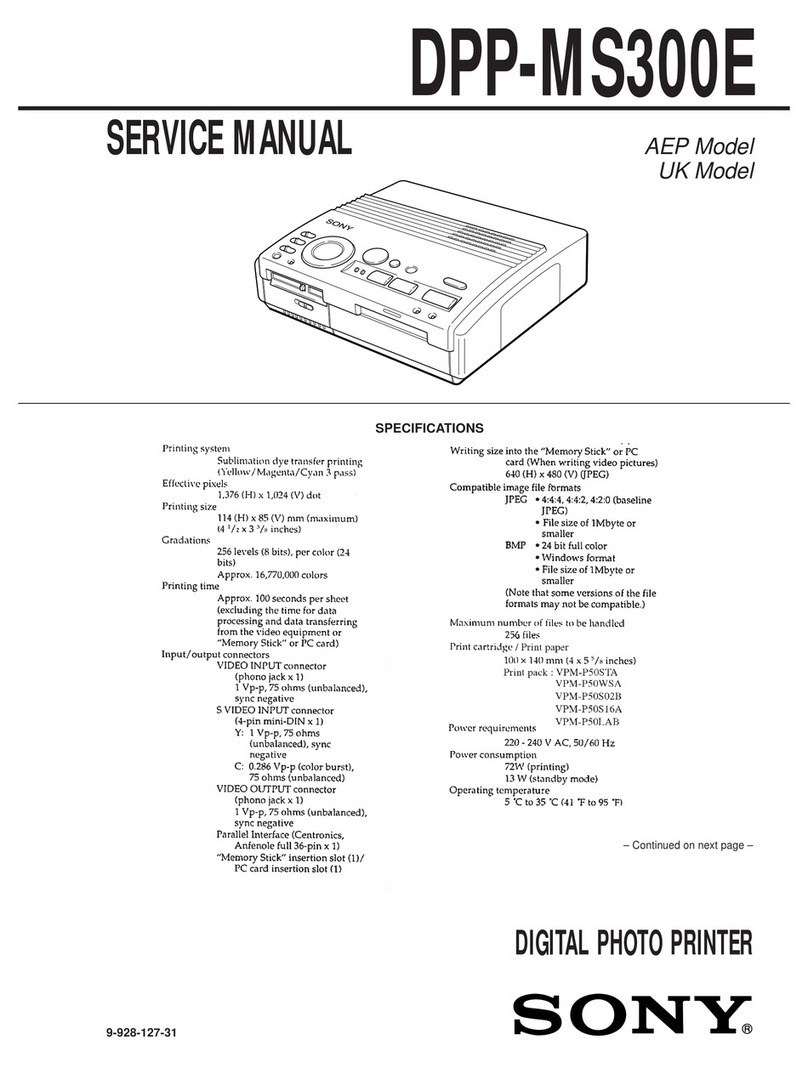

1.

GENERAL

1-1.

Specifications...

ecseecetereereretseensseneneneeneeees

4

1-2.

Location

and

Function

of

Parts...

5

1-8.

OVOPVIOW

0...

ecececeeteesreennseenseesennaeesnaeeaaenecsensnaeteas

6

1-4.

COMMECTION

2.0...

eee

eeeeseetesereeneeseeeneeeteatenssesenseenee

6

1-5.

Before

Printing

............eseseeeseeseeerenectseeseeseseeee

7

1-6.

Loading

Paper...

cceseseeeseeereeseseenenseeeneeneens

9

1-7.

PIMtING.

oo.

eee

eects

eeceteeeeeseneeteeeetenensensnsentnseenenees

10

1-8.

PreCAUtiONS

.......

ee

sceeeceeeeeseeceaseeeenteseecenenssens

12

1-9.

On

the

Type

of

Paper...

ceeseseeeteeeteees

13

1-10.

Troubleshooting

..........ccccceeeseseeseeetereeeseeerecees

14

2.

DISASSEMBLY

2-1.

Removing

the

Top

Cover........eecrscesececceses

15

2-2.

Removing

the

Door

Panel

and

Front

Panel

Unit...

esessscssseesseeerseseeereseees

15

2-3.

Removing

the

MA-19

Board.........

cess

16

2-4.

Removing

the

Mechanism

Block

.................+

16

2-5.

Removing

the

Shield

Case

and

Switching

ReQulator

...........cccecceeeessnseeeeeseees

17

2-6.

Removing

the

Thermal

Head

.............

18

3.

ADJUSTMENTS

3-1.

Head

Voltage

Adjustment...

eessesecsees

19

3-2.

Brightness

Contrast

Adjustment...............:+

19

3-3.

Motor

Speed

Adjustment

..........--ceeeeeeetees

20

4.

DIAGRAMS

4-1.

Circuit

Boards

Location

.........

cesses:

21

4-2.

BlOCK

DiaQrarn

.........cccesesceceteeeneeeteseeeneteesnenes

22

4-3.

Printed

Wiring

Boards

and

Schematic

Diagrams

...........sseeeseseeeeerereerees

25

4-4,

S@MICONAUCTOSS

«0...

ce

eeeseesereereeteetecseneeeneeeees

39

Section

Page

5.

CIRCUIT

DESCRIPTION

5-1.

Video

Circuit...

ees

ssseceeesneenteeseretseneeerseee

46

5-5-1.

Operation

........ceccsssscsessecsecerenenseesssensenneneees

46

5-2.

Oscillation

Circuit

0...

eseeesceeereesneeneeenees

47

5-3.

Peripheral

Circuit

10103

............ceseseeeeeees

48

5-3-1.

Operation

description

...........ceeeesereesees

48

5-4.

System

Control

Section

..........eecseseeeeeneees

51

5-4-1.

Memory

write

(FETCH)

signals

from

the

Print

KOY....eceseeteeeteneeetsatensenees

51

5-4-2.

From

memory

writing

till

screen

PIII

0...

eeesessceeceetenencceeenetenentenseereesoneens

52

5-4-3.

MOE

St

on.

.ceecesesccssccesssnceeesssneeseserereerssensaees

54

5-5.

Motor

Drive

S@ction

0.0...

cccesesscesseseeseennersees

55

5-5-1.

Platem

Motor

ou...

cceecesscccessseeeentesterereeteeeens

55

5-5-2.

Head

U/D

motor

and

DOOR

motor........

55

5-6.

Thermal

Head

Section

...........cesessseereceseees

56

5-6-1.

COnmfiguration

.........ccsccseseeesssereeeeseerersesateres

56

5-6-2.

Timing

Chatto...

.cesseseseseneeeeeereecectseenees

56

5-6-3.

Basic

OPeration

ou...

ccsceceescrerereereeereseneees

57

5-6-4.

Stair

GENeration

20...

eccecseeeenesteeseeeeees

57

5-6-5.

Temperature

compensation..........seee

58

6.

EXPLODED

VIEWS

6-1.

Chassis

S@CtiON

00...

ccscsseeseteeeteecerrteeeseseees

59

6-2.

Print

Mechanism

Section

(1)...

61

6-3.

Print

Mechanism

Section

(2)...

63

7.

ELECTRICAL

PARTS

LIST

.............:

ee

65