Content

1Basic Information...........................................................................................- 3 -

2Introdution......................................................................................................- 3 -

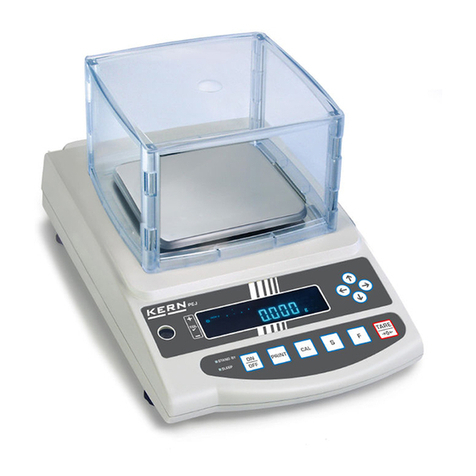

3Keyboard overview ........................................................................................- 4 -

3.1 Overview of display...............................................................................................................- 5 -

3.2 Removing the case................................................................................................................- 6 -

3.3 Attaching the case.................................................................................................................- 7 -

4Trouble shooting table ..................................................................................- 8 -

4.1 Initial inspection ....................................................................................................................- 9 -

5Troubleschooting procedure ......................................................................- 10 -

6Inspection of electrical section (AJDP circuit board)................................- 11 -

7Adjustment ...................................................................................................- 12 -

7.1 Adjustment with internal weight (only models PNJ)........................................................- 12 -

7.2 Adjustment with external weight (only models PNS) ......................................................- 13 -

7.3 CALIBRATION OF BUILT-IN WEIGHT (REFCAL)..............................................................- 15 -

7.4 Resetting address data and linearity calibration..............................................................- 17 -

7.5 Resetting address data (coefficients)................................................................................- 18 -

7.5.1 Location for where to attach..................................................................................... - 18 -

7.5.2 How to read the data sheet....................................................................................... - 18 -

7.6 Linearity calibration ............................................................................................................- 19 -

7.7 Corner Error Adjustment ....................................................................................................- 20 -

7.8 Overload adjustment...........................................................................................................- 22 -

8Replacing the AJDP circuit board ..............................................................- 23 -

8.1 How to remove the AJDP circuit board.............................................................................- 23 -

8.2 Install the AJDP circuit board ............................................................................................- 25 -

9Removing the mechanism unit...................................................................- 27 -