Keysight Technologies E1460A User manual

Keysight E1460A 64-Channel

Relay Multiplexer

Service Manual

75000 Series C

Notices

© Keysight Technologies, Inc. 1996-2019

No part of this manual may be repro-

duced in any form or by any means

(including electronic storage and retrieval

or translation into a foreign language)

without prior agreement and written con-

sent from Keysight Technologies, Inc. as

governed by United States and interna-

tional copyright laws.

Manual Part Number

E1460-90012

Edition

Fourth Edition, April 2019

Published by

Keysight Technologies, Inc.

900 S. Taft Ave.

Loveland, CO 80537 USA

Sales and Technical Support

To contact Keysight for sales and techni-

cal support, refer to the support links on

the following Keysight websites:

www.keysight.com/find/E1460A

(product-specific information and sup-

port, software and documentation

updates)

www.keysight.com/find/assist (world-

wide contact information for repair and

service)

Declaration of Conformity

Declarations of Conformity for this prod-

uct and for other Keysight products may

be downloaded from the Web. Go to

http://keysight.com/go/conformity and

click on “Declarations of Conformity.” You

can then search by product number to

find the latest Declaration of Conformity.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such

license.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,” AND

IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDI-

TIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WAR-

RANTIES, EITHER EXPRESS OR IMPLIED,

WITH REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS OR

FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY INFOR-

MATION CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A SEP-

ARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Keysight Technologies does not warrant

third-party system-level (combination of

chassis, controllers, modules, etc.) per-

formance, safety, or regulatory compli-

ance unless specifically stated.

DFARS/Restricted Rights

Notices

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer soft-

ware” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause.

Use, duplication or disclosure of Software

is subject to Keysight Technologies’ stan-

dard commercial license terms, and non-

DOD Departments and Agencies of the

U.S. Government will receive no greater

than Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Gov-

ernment users will receive no greater

than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.227-

7015 (b)(2) (November 1995), as applica-

ble in any technical data.

Safety Information

The following general safety precau-

tions must be observed during all

phases of operation of this instrument.

Failure to comply with these precau-

tions or with specific warnings or oper-

ating instructions in the product

manuals violates safety standards of

design, manufacture, and intended use

of the instrument. Keysight Technolo-

gies assumes no liability for the cus-

tomer's failure to comply with these

requirements.

General

Do not use this product in any manner not

specified by the manufacturer. The protec-

tive features of this product must not be

impaired if it is used in a manner specified in

the operation instructions.

Before Applying Power

Verify that all safety precautions are taken.

Make all connections to the unit before

applying power. Note the external markings

described under “Safety Symbols”.

Ground the Instrument

Keysight chassis’ are provided with a

grounding-type power plug. The

instrument chassis and cover must be

connected to an electrical ground to

minimize shock hazard. The ground pin

must be firmly connected to an electri-

cal ground (safety ground) terminal at

the power outlet. Any interruption of

the protective (grounding) conductor

or disconnection of the protective

earth terminal will cause a potential

shock hazard that could result in per-

sonal injury.

Do Not Operate in an Explosive

Atmosphere

Do not operate the module/chassis in

the presence of flammable gases or

fumes.

Do Not Operate Near Flammable

Liquids

Do not operate the module/chassis in

the presence of flammable liquids or

near containers of such liquids.

Cleaning

Clean the outside of the Keysight mod-

ule/chassis with a soft, lint-free,

slightly dampened cloth. Do not use

detergent or chemical solvents.

Do Not Remove Instrument Cover

Only qualified, service-trained person-

nel who are aware of the hazards

involved should remove instrument

covers. Always disconnect the power

cable and any external circuits before

removing the instrument cover.

Keep away from live circuits

Operating personnel must not remove

equipment covers or shields. Proce-

dures involving the removal of covers

and shields are for use by service-

trained personnel only. Under certain

conditions, dangerous voltages may

exist even with the equipment

switched off. To avoid dangerous elec-

trical shock, DO NOT perform proce-

dures involving cover or shield removal

unless you are qualified to do so.

DO NOT operate damaged

equipment

Whenever it is possible that the safety

protection features built into this prod-

uct have been impaired, either through

physical damage, excessive moisture,

or any other reason, REMOVE POWER

and do not use the product until safe

operation can be verified by service-

trained personnel. If necessary, return

the product to a Keysight Technologies

Sales and Service Office for service and

repair to ensure the safety features are

maintained.

DO NOT block the primary

disconnect

The primary disconnect device is the

appliance connector/power cord when

a chassis used by itself, but when

installed into a rack or system the dis-

connect may be impaired and must be

considered part of the installation.

Do Not Modify the Instrument

Do not install substitute parts or per-

form any unauthorized modification to

the product. Return the product to a

Keysight Sales and Service Office to

ensure that safety features are main-

tained.

In Case of Damage

Instruments that appear damaged or

defective should be made inoperative

and secured against unintended oper-

ation until they can be repaired by

qualified service personnel

Do NOT block vents and fan exhaust:

To ensure adequate cooling and venti-

lation, leave a gap of at least 50mm

(2") around vent holes on both sides of

the chassis.

Do NOT operate with empty slots: To

ensure proper cooling and avoid dam-

aging equipment, fill each empty slot

with an AXIe filler panel module.

Do NOT stack free-standing chassis:

Stacked chassis should be rack-

mounted.

All modules are grounded through the

chassis: During installation, tighten

each module's retaining screws to

secure the module to the chassis and

to make the ground connection.

Operator is responsible to maintain

safe operating conditions. To ensure

safe operating conditions, modules

should not be operated beyond the full

temperature range specified in the

Environmental and physical specifica-

tion. Exceeding safe operating condi-

tions can result in shorter lifespan,

improper module performance and

user safety issues. When the modules

are in use and operation within the

specified full temperature range is not

maintained, module surface tempera-

tures may exceed safe handling condi-

tions which can cause discomfort or

burns if touched. In the event of a

module exceeding the full temperature

range, always allow the module to cool

before touching or removing modules

from the chassis.

4

Safety Symbols

A CAUTION denotes a hazard. It

calls attention to an operating pro-

cedure or practice, that, if not cor-

rectly performed or adhered to

could result in damage to the

product or loss of important data.

Do not proceed beyond a CAUTION

notice until the indicated condi-

tions are fully understood and met.

A WARNING denotes a hazard. It

calls attention to an operating pro-

cedure or practice, that, if not cor-

rectly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indi-

cated conditions are fully under-

stood and met.

Products display the following sym-

bols:

Warning, risk of electric

shock

Refer to manual for addi-

tional safety information.

Earth Ground.

Chassis Ground.

Alternating Current (AC).

Direct Current (DC)

5

6

Keysight E1460A 64-Channel Relay Multiplexer Service Guide 7

1 General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Relay Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

End-of-Life Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Replacement Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warnings and Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Incoming Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shipping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multiplexer Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multiplexer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multiplexer Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multiplexer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Schematics/ Component Locators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Recommended Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 Verification Tests

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test Conditions/Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Verification Test Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Self-test Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Keysight E1460A Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Test 2-1: Closed-channel Resistance Test . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Example: Closed-channel Resistance Test. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Test 2-2. Testing Control Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Example: Control Relay Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Test 2-3: DC Isolation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Example: DC Isolation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Performance Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contents

8 Keysight E1460A 64-Channel Relay Multiplexer Service Guid

Test Accuracy Ratio (TAR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3 Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Service Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Identifying the Problem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Testing the Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Matching Relays to Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Repair/ Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Soldering Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Post-Repair Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Component Locators and Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 63

A Verification Tests - C Programs

Functional Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Test 2-1: Closed Channel Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Test 2-2: Testing Control Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Test 2-3: DC Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Keysight E1460A 64-Channel Relay Multiplexer

Service Guide

11

1General Information

Introduction

This manual contains information required to test, troubleshoot, and repair the

Keysight E1460A relay multiplexer module (see Figure 1-1).

Figure 1-1 Keysight E1460A Relay Multiplexer Module

12 Keysight E1460A 64-Channel Relay Multiplexer Service Guide

General Information Relay Life

Relay Life

Electromechanical relays are subject to normal wear-out. Relay life depends on

several factors. The effects of loading and switching frequency are briefly

discussed below:

Relay Load. In general, higher power switching reduces relay life. In addition,

capacitive/inductive loads and high inrush currents (e.g., when turning on a lamp

or motor) reduce relay life. Exceeding the specified maximum inputs can cause

catastrophic failure.

Switching Frequency. Relay contacts heat up when switched. As the switching

frequency increases, the contacts have less time to dissipate heat. The resulting

increase in contact temperature reduces relay life.

End-of-Life Detection

A preventive maintenance routine can prevent problems caused by unexpected

relay failure. The end of the life of a relay can be determined using one or more of

the three methods described below. The best method (or combination of

methods), as well as the failure criteria, depends on the application in which the

relay is used.

Contact Resistance. As the relay begins to wear out, its contact resistance will

increase. When the resistance exceeds a pre-determined value, the relay should

be replaced. The end-of-life resistance recommended by Keysight Technologies

can be found in Appendix A of the Keysight E1460A User’s Manual.

Stability of Contact Resistance. The stability of the contact resistance decreases

with age. Using this method, the contact resistance is measured several (5-10)

times, and the variance of the measurements is determined. An increase in the

variance indicates deteriorating performance.

Number of Operations. Alternatively, relays can be replaced after a

predetermined number of contact closures. However, this method requires

knowledge of the applied load and life specifications for the applied load.

Replacement Strategy

The replacement strategy also depends on the application. If some relays are

used more often, or at higher load, than the others, the relays can be individually

replaced as needed. If all of the relays see similar loads and switching

frequencies, the entire circuit board can be replaced when the end of life

approaches. The sensitivity of the application should be weighed against the cost

of replacing relays with some useful life remaining.

Keysight E1460A 64-Channel Relay Multiplexer Service Guide 13

Relay Life General Information

Relays that wear out normally or fail due to misuse should not be

considered defective and are not covered by the product’s

warranty.

14 Keysight E1460A 64-Channel Relay Multiplexer Service Guide

General Information Safety Considerations

Safety Considerations

This product is a Safety Class I instrument that is provided with a protective earth

terminal when installed in the mainframe. The instrument, mainframe, and all

related documentation should be reviewed for familiarization with safety

markings and instructions before operation or service.

Refer to the WARNINGS page (page 4) in this manual for a summary of safety

information. Safety information for testing and service follows and is also found

throughout this manual.

Warnings and Cautions

This section contains WARNINGS which must be followed for your protection

and CAUTIONS which must be followed to avoid damage to the equipment when

performing instrument maintenance or repair.

Keysight E1460A 64-Channel Relay Multiplexer Service Guide 15

Safety Considerations General Information

SERVICE-TRAINED PERSONNEL ONLY. The information in

this manual is for service-trained personnel who are

familiar with electronic circuitry and are aware of the

hazards involved. To avoid personal injury or damage to

the instrument, do not perform procedures in this manual

or do any servicing unless you are qualified to do so.

CHECK MAINFRAME POWER SETTINGS. Before applying

power, verify that the mainframe setting matches the line

voltage and that the correct fuse is installed. An

uninterruptible safety earth ground must be provided from

the main power source to the supplied power cord set.

Note: the Keysight E1401A mainframe automatically

selects the correct line frequency.

GROUNDING REQUIREMENTS. Interruption of the

protective (grounding) conductor (inside or outside the

mainframe) or disconnecting the protective earth terminal

will cause a potential shock hazard that could result in

personal injury. (Grounding one conductor of a

two-conductor outlet is not sufficient protection.)

IMPAIRED PROTECTION. Whenever it is likely that

instrument protection has been impaired, the mainframe

must be made inoperative and be secured against any

unintended operation.

REMOVE POWER IF POSSIBLE. Some procedures in this

manual may be performed with power supplied to the

mainframe while protective covers are removed. Energy

available at many points may, if contacted, result in

personal injury. (If maintenance can be performed without

power applied, the power should be removed.)

16 Keysight E1460A 64-Channel Relay Multiplexer Service Guide

General Information Safety Considerations

USING AUTOTRANSFORMERS. If the mainframe is to be

energized via an autotransformer (for voltage reduction)

make sure the common terminal is connected to neutral

(that is, the grounded side of the mains supply).

CAPACITOR VOLTAGES. Capacitors inside the mainframe

may remain charged even when the mainframe has been

disconnected from its source of supply.

USE PROPER FUSES. For continued protection against fire

hazard, replace the line fuses only with fuses of the same

current rating and type (such as normal blow, time delay,

and so on). Do not use repaired fuses or short-circuited

fuseholders.

SHOCK HAZARD. Only service-trained personnel who are

aware of the hazards involved should install, remove, or

configure the multiplexer. Before you remove any installed

module, disconnect AC power from the mainframe and

from other modules that may be connected to the

multiplexer.

CHANNEL WIRING INSULATION. All channels that have a

common connection must be insulated so that the user is

protected from electrical shock. This means wiring for all

channels must be insulated as though each channel carries

the voltage of the highest voltage channel.

MAXIMUM INPUTS. The maximum voltage that can be applied to

any terminal is 220Vdc/250Vrms. The maximum current that can

be applied to any terminal is 1 A at <30Vdc/Vrms, or 0.3 A at

<220Vdc/250Vrms. The maximum power that can be applied to

any terminal is 40 VA.

STATIC ELECTRICITY. Static electricity is a major cause of

component failure. To prevent damage to the electrical

components in the multiplexer, observe anti-static techniques

whenever working on the device.

Keysight E1460A 64-Channel Relay Multiplexer Service Guide 17

Incoming Inspection General Information

Incoming Inspection

Use the following steps as guidelines to perform initial (incoming) inspection of

the Keysight E1460A.

1If the Keysight E1460A is damaged, contact Keysight Technologies and

contact the carrier.

2Install the Keysight E1460A in a VXI mainframe. Refer to the Keysight E1460A

User Manual and the Keysight Series C Installation and Getting Started Guide

for additional information.

3Perform the Functional Verification test and (optionally) the Performance

Verification tests. Refer to Chapter 2 in this manual.

4If any of the tests do not pass, return the module to Keysight Technologies.

See Shipping Guidelines later n this chapter.

5If all verification tests pass, the module is ready to use.

Shipping Guidelines

Follow the steps in Figure 1-2 to return the relay multiplexer module to an

Keysight Technologies Sales and Support Office or Service Center.

To avoid possible hazardous electrical shock, do not

perform electrical tests if there are signs of shipping

damage to the shipping container or to the instrument.

18 Keysight E1460A 64-Channel Relay Multiplexer Service Guide

General Information Incoming Inspection

We recommend that you use the same shipping materials as those used in factory packaging (available from Keysight Technologies). For

other (commercially-available) shipping materials, use a double-wall carton with minimum 2.4 MPa (350 psi) test.

Figure 1-2 Packaging/Shipping Guidelines

1 Prepare the module

–Remove any user wiring.

–Attach tag to device that identifies:

-- Owner

-- Model Number/Serial Number

-- Service Required

–Place tagged device in approved anti-static bag.

2 Package the module

–Place packaged device in shipping carton.*

–Place 75 to 100 mm (3 to 4 inches) of

shock-absorbing material around the module.

–Seal the shipping container securely.

–Mark the shipping container FRAGILE.

3 Ship the module to Keysight Technologies

–Place address label on shipping carton.

–Send carton to Keysight Technologies.

Keysight E1460A 64-Channel Relay Multiplexer Service Guide 19

Environment General Information

Environment

The recommended operating environment for the multiplexer is:

Multiplexer Description

The Keysight E1460A 64-channel relay multiplexer module is an “ instrument” in

the slot of a VXIbus mainframe. Each module is assigned an error queue, input

and output buffers, and a status register.

Multiplexer Specifications

Specifications are listed in Appendix A of the Keysight E1460A User’s Manual.

These specifications are the performance standards or limits against which the

module may be tested.

Multiplexer Serial Numbers

Devices covered by this manual are identified by a serial number prefix listed on

the title page. Keysight Technologies uses a two-part serial number in the form

XXXXAYYYYY, where XXXX is the serial prefix, A is the country of origin

(A=U.S.A.), and YYYYY is the serial suffix. The serial number prefix identifies a

series of identical instruments. The serial number suffix is assigned sequentially

to each instrument. The serial number plate is located on the right-hand shield

near the backplane connectors.

Multiplexer Options

There are no electrical or mechanical options available for the 64-channel relay

multiplexer module.

Environment Temperature Humidity

Operating 0 °C to +55 °C <65% relative (0 °C to +40 °C)

Storage and

Shipment

-40 °C to +75 °C <65% relative (0 °C to +40 °C)

Instruments are based on the logical addresses of the plug-in

modules. See the Keysight 75000 Series C Installation and Getting

Started Guide to set the addresses to create an instrument.

20 Keysight E1460A 64-Channel Relay Multiplexer Service Guide

General Information Recommended Test Equipment

Schematics/ Component Locators

Component locators and schematics for the module are included in this manual.

Recommended Test Equipment

Table 1-1 lists the test equipment recommended for testing and servicing the

module. Essential requirements for each piece of test equipment is described in

the Requirements column.

* F = Functional Verification, O = Operation Verification Tests, P = Performance

Verification Tests, T = Troubleshooting

Table 1-1 Recommended Test Equipment

Instrument Requirements Recommended Model Use*

Controller, GPIB GPIB compatibility as defined by IEEE

Standard 488-1988 and the identical ANSI

Standard MC1.1: SH1, AH1, T2, TE0, L2, LE0,

SR0, RL0, PP0, DC0, DT0, and C1, 2, 3,

4, 5.

HP 9000 Series 300 or

IBM Compatible PC

with BASIC

F,O, P,T

Mainframe Compatible with relay multiplexer E1401B/T E1421B F,O, P,T

Command Module Compatible with relay multiplexer E1405A/B E1406A F,O, P,T

Digital Multimeter 4-wire ohms

2-wire ohms (up to 1 GΩ)

Keysight 3458A or

Keysight 34401A

O,P,T

Keysight E1460A 64-Channel Relay Multiplexer

Service Guide

21

2Verification Tests

Introduction

The two levels of test procedures described in this chapter are used to verify that

the relay multiplexer module:

–is fully functional (Functional Verification);

–meets all testable specifications (Performance Verification).

Test Conditions/Procedures

See Table 1-1 for test equipment requirements. You should complete the

Performance Verification tests at least once a year. For heavy use or severe

operating environments, perform the tests more often. It is assumed that the

temperature is no greater than 25oC and the relative humidity is no greater than

40%.

The verification tests assume that the person performing the tests understands

how to operate the mainframe, the relay multiplexer, and specified test

equipment. The test procedures do not specify equipment settings for test

equipment, except in general terms. It is assumed that a qualified,

service-trained technician will select and connect the cables, adapters, and

probes required for the test.

Performance Test Record

The results of each Performance Verification test may be recorded in the

Performance Test Record (Table 2-1). You can make a copy of this form, if

desired.

Verification Test Examples

Each verification test procedure includes an example program that performs the

test. All example programs assume the following:

–controller is an HP 9000 Series 200/300 computer;

–programming language is BASIC;

–switch address is 70914;

–switch card number is 1;

–DMM is an Keysight 3458A.

22 Keysight E1460A 64-Channel Relay Multiplexer Service Guide

Verification Tests Introduction

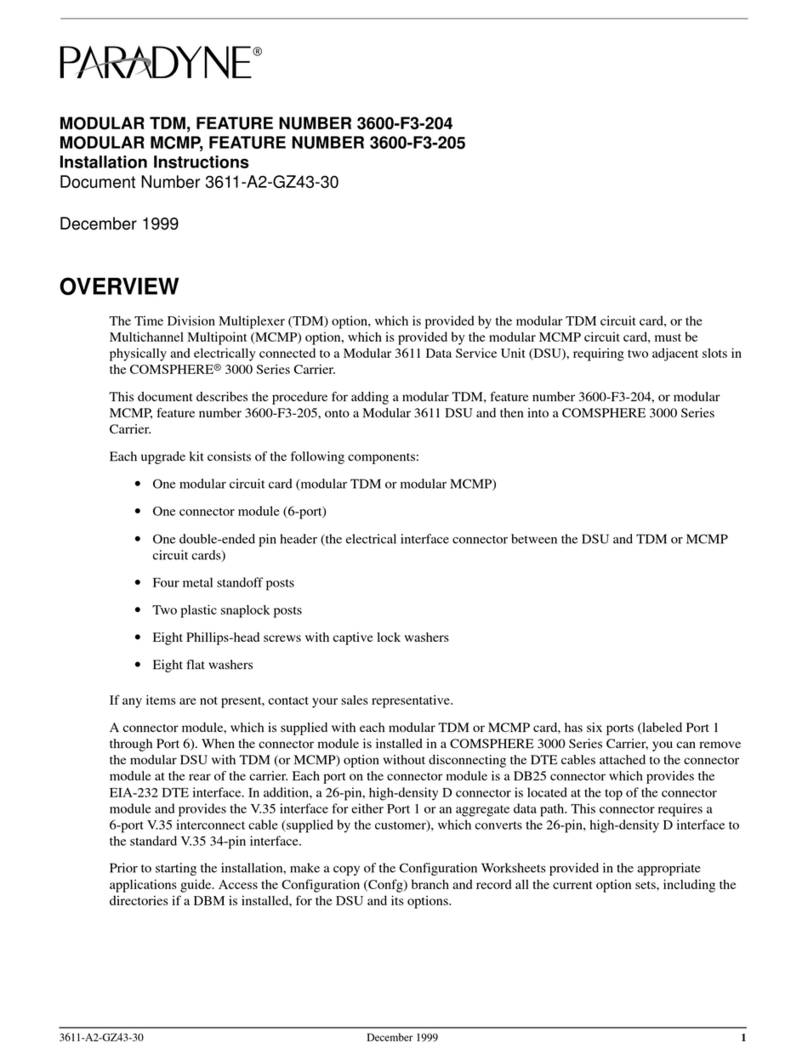

Test Fixture

A test fixture is required for the Performance Verification tests. A test fixture can

be manufactured from the Keysight E1460A terminal block. It is recommended

that you order an extra terminal block to use as a test fixture, so that you do not

have to re-wire the terminal block each time these tests are performed. The

terminal block part number is E1460-80001. Figure 2-1 shows how the test

fixture should be wired.

If you are using an Keysight E1460A terminal block, and some or

all of the relay module jumpers have been removed, you should

add the following connections to the test fixture shown in Figure

2-1:

1. Wire all Common High lines together.

2. Wire all Common Low lines together.

These steps are not necessary if all of the relay card jumpers are in

place.

Figure 2-1 Keysight E1460A Test Fixture

Table of contents

Other Keysight Technologies Multiplexer manuals

Popular Multiplexer manuals by other brands

Panasonic

Panasonic WJFS616 - SWITCHER Operating instruction

RFL Electronics

RFL Electronics eXmux 3500 quick start guide

Vicon

Vicon V5900MUX Installation & operation manual

Televes

Televes T.0X Series quick guide

Paradyne

Paradyne COMSPHERE 3611 installation instructions

SELPRO

SELPRO PMP-410-Ex quick start guide

Vetra

Vetra MegaMux VIP- 882 Series User instruction

Kathrein

Kathrein WFS 28 instructions

RFL

RFL EXMUX 3500 quick start guide

GE Security

GE Security DVMRe Pro user manual

Snell Advanced Media

Snell Advanced Media IQMUX34 User instruction manual

Lucent Technologies

Lucent Technologies Multiplexer and Transport System ADM 16/1 Brochure & specs