6 P/N 3102382-EN • REV 02 • ISS 15DEC16

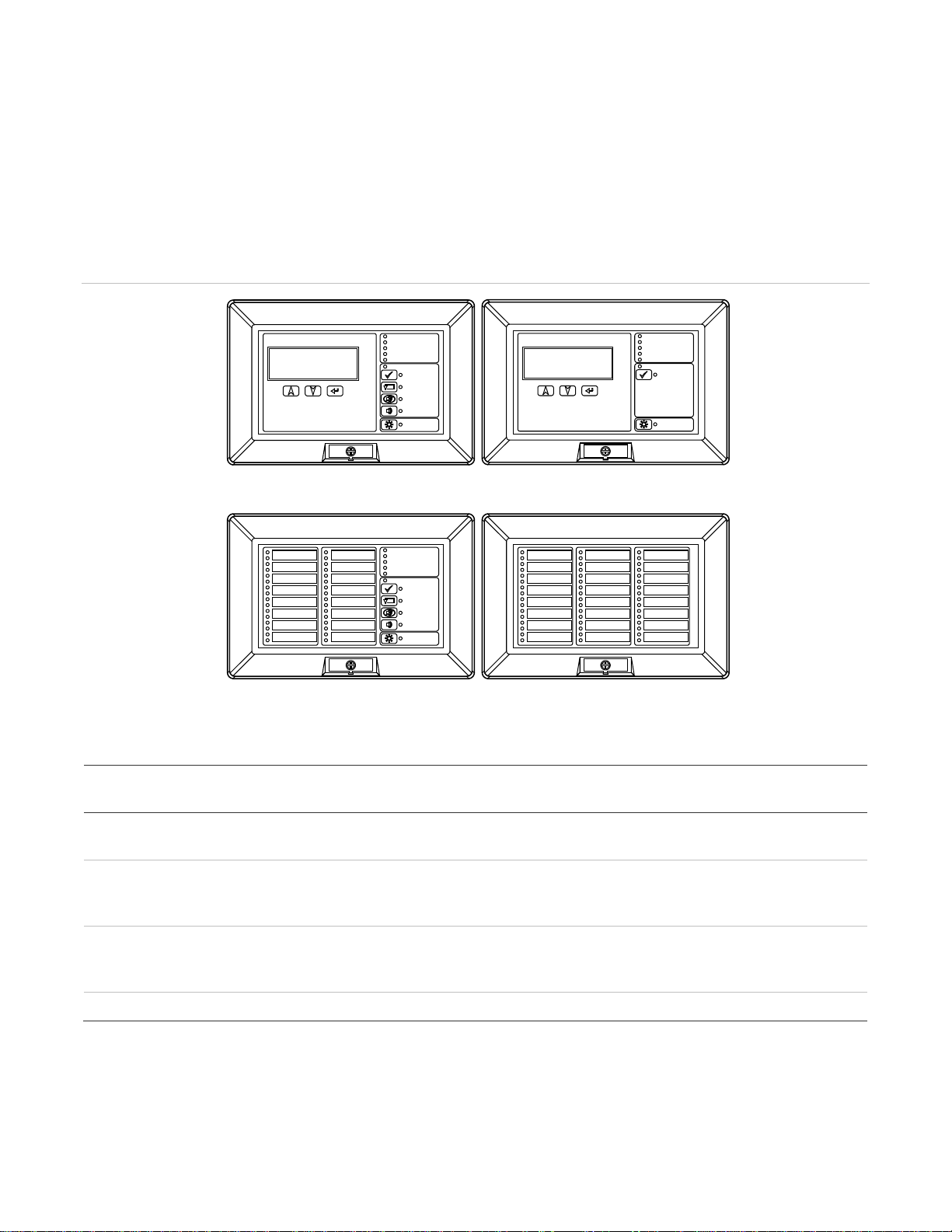

Installing annunciators and expanders

For correct operation, the annunciator must be configured with a unique address, must have the correct baud rate

setting, and must be in communication with the FACP.

If you are installing a Remote Annunciator and Remote Expanders into RA-ENC2 or RA-ENC3 enclosures, you

must install the expanders first. Refer to the installation sheets for the enclosures for the correct sequence of

steps.

If you are installing Remote Annunciators and Remote Expanders using separate electrical boxes, the wire runs

between the boxes must be enclosed in conduit.

If you are installing a remote key switch, the switch must be located within the enclosure or within 3 ft. (0.9 m) of

the enclosure with the cabling installed in conduit or equivalent protection against mechanical injury.

To install an annunciator:

1. Secure the mounting ring to the electrical box, as shown in Figure 4.

2. Use the DIP switch to set the correct address and baud rate. See Table 3 on page 5 for DIP switch settings.

3. Connect the control panel annunciator circuit to the appropriate annunciator terminals. See Figure 5, Figure 6,

Figure 7, and Figure 8.

Tip: Leave enough wire to remove and position the annunciator when setting the DIP switch.

4. Attach the expander cable to the annunciator, if applicable. See Figure 9.

5. Attach the remote key switch wiring to the annunciator, if applicable. See Figure 8.

6. Tilt the annunciator up and slide the mounting slot onto the top flange of the mounting ring, as shown in

Figure 4.

7. Tilt the annunciator down and push the bottom of the annunciator over the stud-nut.

8. Secure the bottom of the annunciator to the mounting ring using the captive screw.

9. Cover the screw hole with the product label plate.

To install an expander:

1. Complete and insert the zone card (labeling sheet) into the expander.

2. Secure the mounting ring to the electrical box, as shown in Figure 4.

3. Connect the expander cable to the expander. Attach an expander cable for interconnection to a second

expander, if applicable. See Figure 9.

4. Tilt the expander up and slide the mounting slot onto the top flange of the mounting ring, as shown in

Figure 4.

5. Tilt the expander down and push the bottom of the expander over the stud-nut.

6. Secure the bottom of the expander to the mounting ring using the captive screw.

7. Cover the screw hole with the product label plate.

8. Repeat steps 1 through 7 for a second expander, if applicable.