© 2020 Carrier 1 / 6 P/N 3101069-EN • REV 005 • ISS 19OCT20

FX-PDD Duct Smoke

Detector Installation Sheet

Description

The FX-PDD Duct Smoke Detector is designed for use in duct

applications where temperatures can exceed standard detector

capabilities.

The device address is set using the two rotary switches located on

the front of the unit. One device address is required.

In installations where the controls and indicators are hidden from

view, a remote test station or an LED indicator can be connected to

the detector to provide these functions.

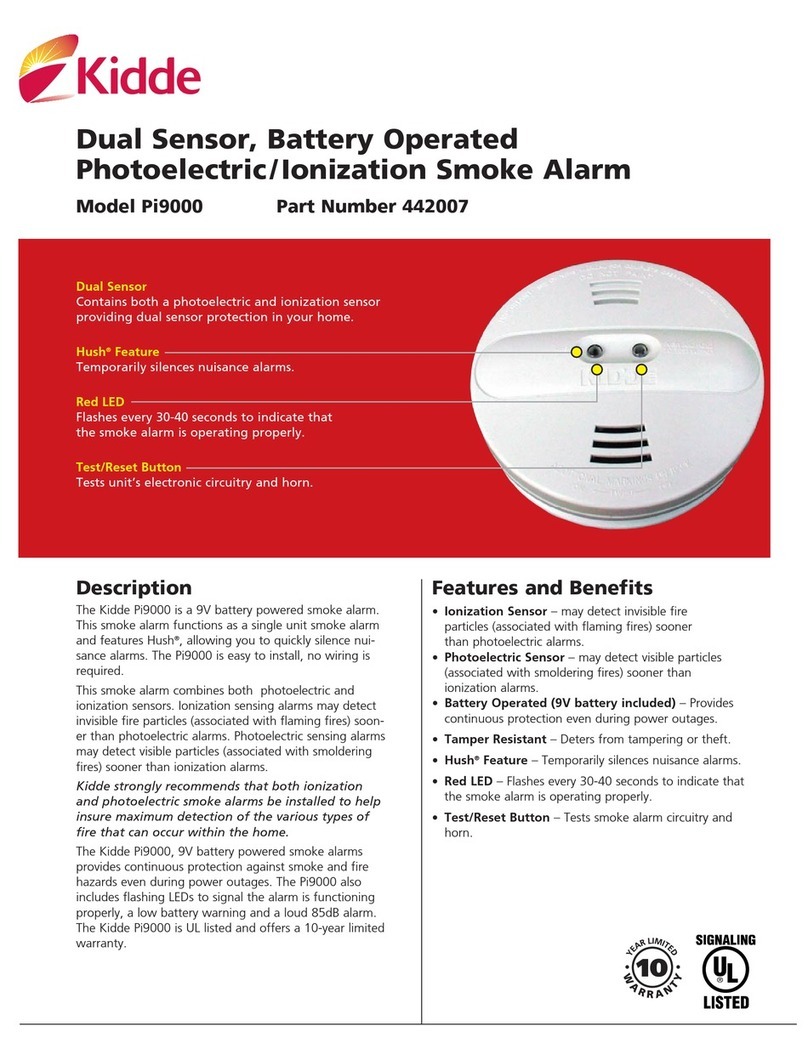

Jumper settings

The following jumper settings determine the operation of the

detector. See Figure 6 for proper jumper location.

Table 1: JP3 jumper settings

Description

Configures the detector for alarm latching

operation.

Configures the detector for supervisory

operation.

This is the factory default setting.

LED operation

Two LEDs, visible from the front of the detector, show its status.

Table 2: LEDs

Description

Off when the detector is in the alarm state.

Flashes intermittently when the detector is in

the normal state.

Indicates the detector is in the alarm/active

state.

Installation

WARNINGS

• The duct smoke detector is not intended as a substitute for open

area protection.

• This detector does not operate without electrical power. As fires

frequently cause power interruption, discuss further safeguards

with the local fire protection specialist.

• The duct smoke detector does not operate as designed outside

of the listed electrical and environmental specifications.

• The duct smoke detector does not sense smoke unless the

ventilation system is operating and the sensor’s cover is

properly installed.

• The duct smoke detector may not operate as designed unless

installed in accordance with these instructions and all applicable

national and local codes as determined by the local authority

having jurisdiction.

Note: Read these instructions thoroughly before installing. Refer to

Application Bulletin P/N 3101107 for additional information regarding

installation instructions.

Installation guidelines

To ensure correct operation, install the duct detector using the

following guidelines:

• Install the duct smoke detector on a flat section of HVAC duct

between six and ten duct widths from any bends or obstructions.

• Install supply-side detectors at a point downstream from the

supply fan and after the air filter.

• Install return-side detectors at a point before the return air

stream is diluted by outside air.

Verifying the duct air velocity

In order to verify the airflow direction and velocity, air must be

moving through the HVAC system.

To verify the duct air velocity:

1. Drill a small hole at the point where the duct smoke detector is

being installed.

2. Using the SD-VTK Air Velocity Test Kit and a suitable air

velocity meter, verify that the air velocity in the HVAC duct falls

within the specified operating range of the detector and note

which direction the air flows.

3. If the air velocity does not fall within the specified range, relocate

the detector and seal the hole in the HVAC duct. Refer to

Application Bulletin P/N 3101107 for additional information

pertaining to installation locations.