2 / 4 P/N 3102678-EN • REV 001 • ISS 02DEC20

4. If required by the AHJ or local codes, affix the supplied CO

Warning Label (P/N 3303928) in proximity to the detector.

Figure 1: Setting detector address (address 52 shown)

(1) Insert a screwdriver here to set the address

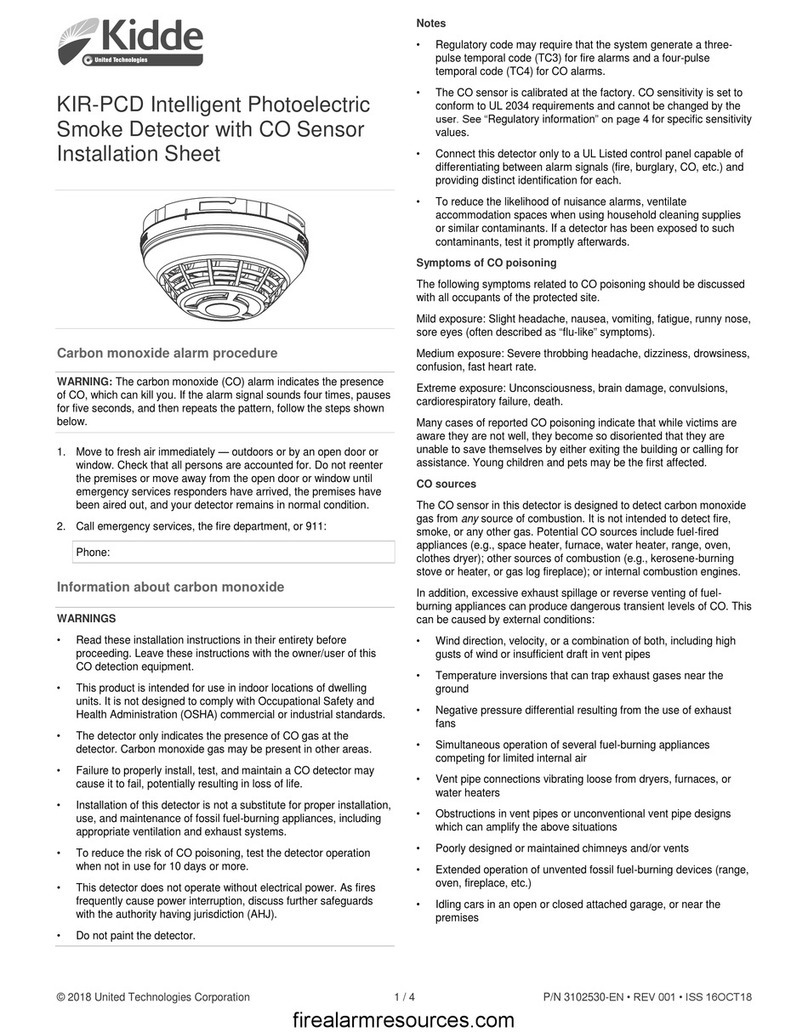

Carbon monoxide alarm procedure

WARNING: The carbon monoxide (CO) alarm indicates the presence

of CO, which can kill you. If the alarm signal sounds four times, pauses

for five seconds, and then repeats the pattern, follow the steps shown

below.

1. Move to fresh air immediately — outdoors or by an open door or

window. Check that all persons are accounted for. Do not reenter

the premises or move away from the open door or window until

emergency services responders have arrived, the premises have

been aired out, and your detector remains in normal condition.

2. Call emergency services, the fire department, or 911:

Phone:

Information about carbon monoxide

WARNINGS

• Read these installation instructions in their entirety before

proceeding. Leave these instructions with the owner/user of this

CO detection equipment.

• This product is intended for use in indoor locations of dwelling

units. It is not designed to comply with Occupational Safety and

Health Administration (OSHA) commercial or industrial standards.

• The detector only indicates the presence of CO gas at the

detector. Carbon monoxide gas may be present in other areas.

• Failure to properly install, test, and maintain a CO detector may

cause it to fail, potentially resulting in loss of life.

• Installation of this detector is not a substitute for proper installation,

use, and maintenance of fossil fuel-burning appliances, including

appropriate ventilation and exhaust systems.

• To reduce the risk of CO poisoning, test the detector operation

when not in use for 10 days or more.

• This detector does not operate without electrical power. As fires

frequently cause power interruption, discuss further safeguards

with the authority having jurisdiction (AHJ).

• Do not paint the detector.

Notes

• Regulatory code may require that the system generate a three-

pulse temporal code (TC3) for fire alarms and a four-pulse

temporal code (TC4) for CO alarms.

• The CO sensor is calibrated at the factory. CO sensitivity is set to

conform to UL 2034 requirements and cannot be changed by the

user. See “Regulatory information” on page 4 for specific

sensitivity values.

• Connect this detector only to a UL Listed control panel capable of

differentiating between alarm signals (fire, burglary, CO, etc.) and

providing distinct identification for each.

• To reduce the likelihood of nuisance alarms, ventilate

accommodation spaces when using household cleaning supplies

or similar contaminants. If a detector has been exposed to such

contaminants, test it promptly afterwards.

Symptoms of CO poisoning

The following symptoms related to CO poisoning should be discussed

with all occupants of the protected site.

Mild exposure: Slight headache, nausea, vomiting, fatigue, runny nose,

sore eyes (often described as “flu-like” symptoms).

Medium exposure: Severe throbbing headache, dizziness, drowsiness,

confusion, fast heart rate.

Extreme exposure: Unconsciousness, brain damage, convulsions,

cardiorespiratory failure, death.

Many cases of reported CO poisoning indicate that while victims are

aware they are not well, they become so disoriented that they are

unable to save themselves by either exiting the building or calling for

assistance. Young children and pets may be the first affected.

CO sources

The CO sensor in this detector is designed to detect carbon monoxide

gas from any source of combustion. It is not intended to detect fire,

smoke, or any other gas. Potential CO sources include fuel-fired

appliances (e.g., space heater, furnace, water heater, range, oven,

clothes dryer); other sources of combustion (e.g., kerosene-burning

stove or heater, or gas log fireplace); or internal combustion engines.

In addition, excessive exhaust spillage or reverse venting of fuel-

burning appliances can produce dangerous transient levels of CO.

This can be caused by external conditions:

• Wind direction, velocity, or a combination of both, including high

gusts of wind or insufficient draft in vent pipes

• Temperature inversions that can trap exhaust gases near the

ground

• Negative pressure differential resulting from the use of exhaust

fans

• Simultaneous operation of several fuel-burning appliances

competing for limited internal air

• Vent pipe connections vibrating loose from dryers, furnaces, or

water heaters

• Obstructions in vent pipes or unconventional vent pipe designs

which can amplify the above situations

• Poorly designed or maintained chimneys and/or vents

• Extended operation of unvented fossil fuel-burning devices (range,

oven, fireplace, etc.)

• Idling cars in an open or closed attached garage, or near the

premises

General limitations of CO detectors

This detector is designed to protect individuals from the acute affects

of CO exposure. It will not fully safeguard individuals with specific

medical conditions. People with special medical problems should

consider using specialized detection devices with less than 30 ppm

(parts per million) alarming capabilities. If in doubt, consult a medical

practitioner.

If the detector is in trouble or at the end of its life, it may not sense CO

and cannot be relied upon to monitor CO levels. Replace the detector

every ten years from the date of manufacture or when the control

panel indicates a sensor end-of-life condition, whichever comes first.

A detector installed outside a bedroom may not awaken a sleeper.

Normal noise due to stereos, television, etc. may also prevent the

detector from being heard if distance or closed or partly closed doors

muffle the sounder. This unit is not designed for the hearing impaired.

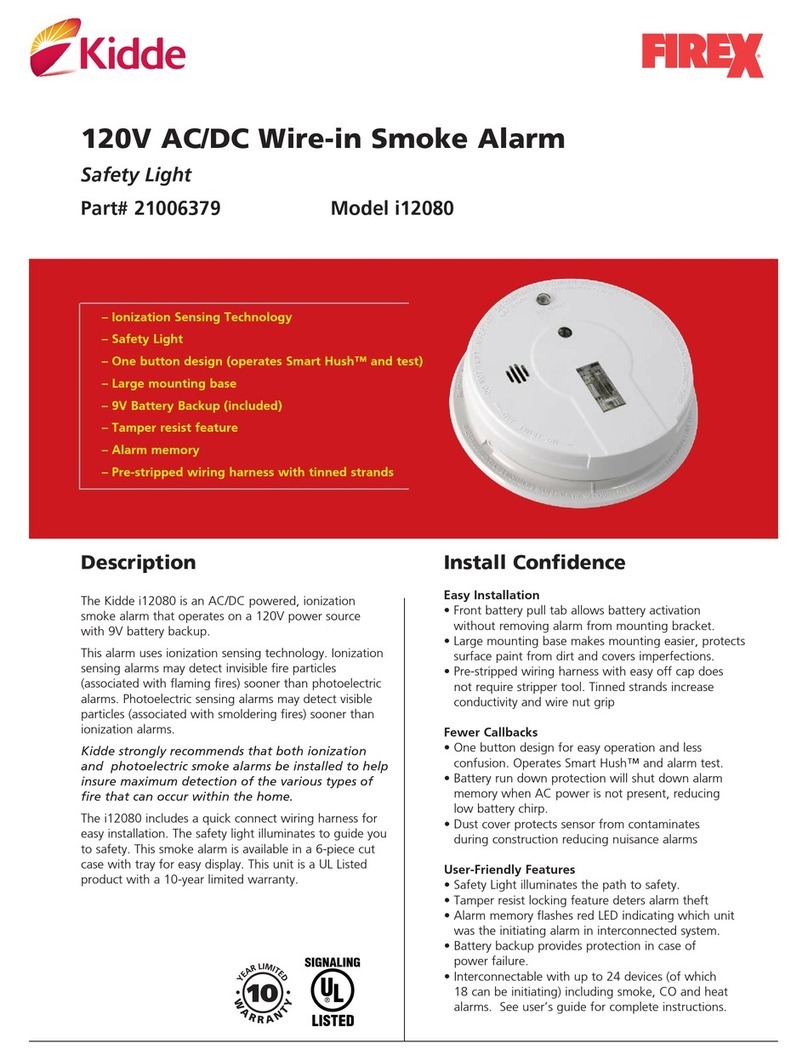

0

2

345

6

8

9

0

1

2

456789

01

11

11

2

TENS ONE