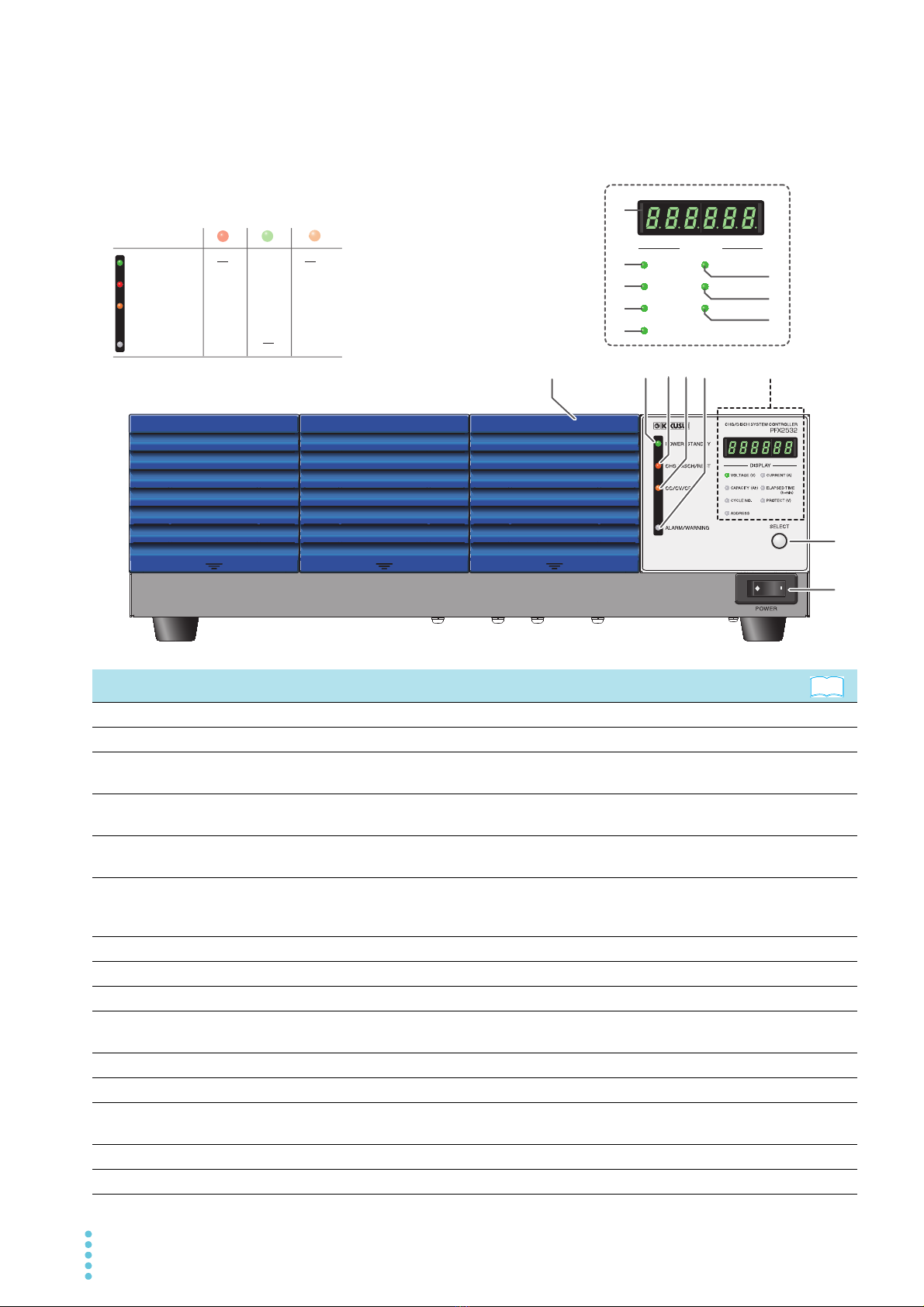

6PFX2532

Be sure to observe the following precautions

when installing the product.

• Do not use the product in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the

product near alcohol, thinner, or other combustible materials,

or in an atmosphere containing such vapors.

• Avoid locations where the product is exposed to high

temperature or direct sunlight.

Do not install the product near a heater or in areas subject to

drastic temperature changes.

Operating temperature range: 0 °C to +40 °C (32 °F to 104 °F)

Storage temperature range: -10 °C to +60 °C (14 °F to 140 °F)

•Avoidhumidenvironments.

Do not install the product in high-humidity locations such as

near a boiler, humidifier, or water supply.

Operating humidity range: 20 %rh to 85 %rh (no condensation)

Storage humidity range : 0 %rh to 90 %rh (no condensation)

Condensation may form even within the operating humidity

range. If this happens, do not use the product until the

condensation dries up completely.

• Be sure to use the product indoors.

This product is designed for safe indoor use.

• Do not install the product in a corrosive atmosphere.

Do not install the product in a corrosive atmosphere or in

environments containing sulfuric acid mist, etc. This may cause

corrosion of various conductors or reduce the quality of the

connector contacts inside the product, and this could lead to

malfunction, failure, and possibly fire.

• Do not install the product in a dusty location.

Dust accumulation can lead to electric shock or fire.

• Do not use the product in a poorly ventilated location.

Provide adequate space around the product for air to circulate

around it.

• Do not place objects on top of the product.

Placing heavy objects on top of the product may cause

malfunction.

• Do not install the product on an inclined surface or in a location

subject to vibrations.

The product may fall or tip over and cause damage and injury.

• Do not use the product in a location subject to strong magnetic

or electric fields or in a location where the input power supply

signal contains large amounts of distortion or noise.

Doing so may cause the product to malfunction.

• Use the product in an industrial environment.

This product may cause interference if used in residential areas.

Such use must be avoided unless the user takes special

measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

•ForKCmark.

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는

이 점을 주의하시기 바라며 , 가정외의 지역에서 사용하는 것을 목적

으로 합니다 .

• In this manual, the PFX2532 Charge/Discharge System

Controller is also referred to as the PFX2532 or the PFX2500

series.

• Application software BPChecker3000 is also referred to as

BPChecker3000.

• The PWR-01 Series Regulated DC Power Supply is also referred

to as the PWR-01.

• The PWR Series Regulated DC Power Supply is also referred to as

the PWR.

• The PAT-T Series Regulated DC Power Supply is also referred to

as the PAT-T.

• The PLZ-5W Series Electronic Load is also referred to as the PLZ-

5W.

• The PLZ-4W Series Electronic Load is also referred to as the PLZ-

4W.

• The PLZ2405WB Electronic Load Booster is also referred to as

the PLZ2405WB.

• The PLZ2004WB Electronic Load Booster for the PLZ-4W Series

Electronic Load is also referred to as the PLZ2004WB.

• The OP02-PFX Volt/Thermometer Unit is also referred to as the

OP02-PFX.

• The OP03-PFX Voltmeter Unit is also referred to as the OP03-

PFX.

• The SL01-PFX 8Slot Unit is also referred to as the SL01-PFX.

• The EX01-PFX board for connecting the PFX2532 and the SL01-

PFX is also referred to as the EX01-PFX.

• The term “PC” is used to refer generally to both personal

computers and workstations.

• The following markings are used in the explanations in this

manual.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product or other

property.

Indicates information that you should know.

Indicates reference to detailed information.

Indicates reference to detailed information operation manual.

Indicates reference to detailed information help file.

Indicates useful information.

Precautions Concerning Installation

Notations used in this manual

Ope