Kilpatrick Format

Technical Specications

Table of Contents

Introduction................................................................................................................................................4

A Few Words of Welcome.....................................................................................................................5

Use of the Kilpatrick Format Specification...............................................................................................6

Namin Requirements...........................................................................................................................6

Keep Kilpatrick Audio Informed...........................................................................................................6

Errors, Omissions and Su estions.......................................................................................................6

Physical Specifications..............................................................................................................................7

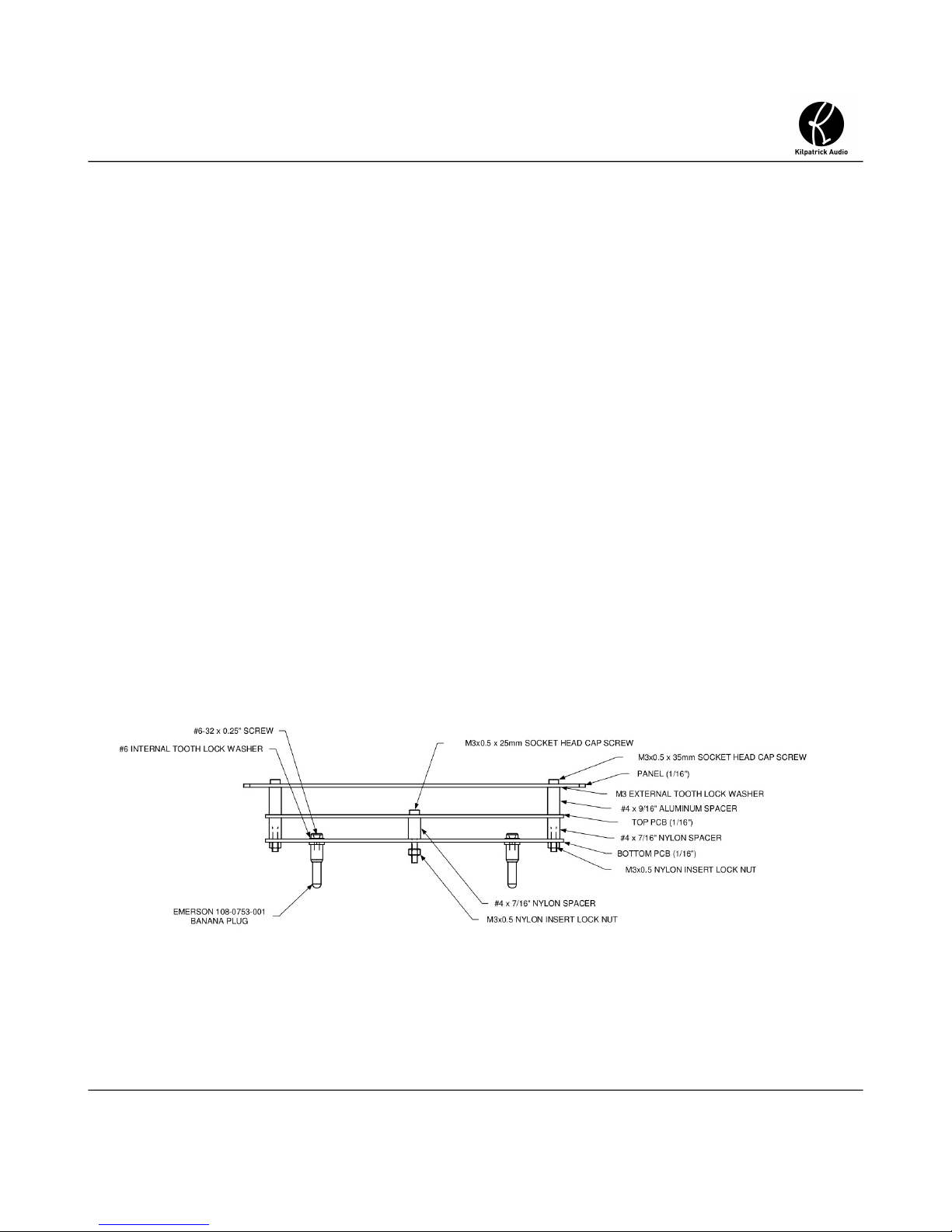

Module Stack-up Overview...................................................................................................................7

Panel Material........................................................................................................................................8

Panel Retainin Screw...........................................................................................................................9

Module Power Plu s...........................................................................................................................10

Module Stack-up Details.....................................................................................................................11

Panel Dimensions and Thickness........................................................................................................12

PCB Dimensions and Thickness.........................................................................................................12

Panel to Top PCB Spacin ..................................................................................................................12

Top PCB to Bottom PCB Spacin .......................................................................................................13

Enclosures................................................................................................................................................14

Module Mountin Plate.......................................................................................................................15

Power Supply......................................................................................................................................16

Active / Passive Enclosure Interconnect.............................................................................................17

Connectin Multiple Active Enclosures..............................................................................................17

Power Wirin and Power Supplies...........................................................................................................18

Analo and Di ital Grounds................................................................................................................18

System Power Groundin ....................................................................................................................19

Power Supplies on Modules................................................................................................................19

Audio and Control Si nals.......................................................................................................................20

Si nal Impedance................................................................................................................................20

Input and Output Volta e Ran e.........................................................................................................20

Gates and Pulses..................................................................................................................................21

Audio and CV Si nals.........................................................................................................................21

Indicator LEDs.........................................................................................................................................21

Module Desi n Techniques......................................................................................................................22

Module Power Supply Example..........................................................................................................22

Pulse Input Circuit...............................................................................................................................23

+3.3V to +5V Pulse Amplifier.............................................................................................................24

Bi-colour LED Driver.........................................................................................................................25

07/02/2014 Page 2 of 29

web: www.kilpatrickaudio.com – email: info@kilpatrickaudio.com