2

WARNING: Cancer and Reproductive Harm –www.p65warnings.ca.gov.

SAFETY PRECAUTIONS:

1. This power tool is not intended for use in potentially explosive atmospheres and is not insulated

against electricity.

2. Always wear face, hand and impact-resistant eye protection when operating this tool.

3. High sound levels can cause permanent hearing loss. Always use hearing protection as required

by health and safety regulations. Operate and maintain the power tool to prevent unnecessary

increase in noise level.

4. Never carry the tool by the air hose and beware of hose whip when disconnecting the tool.

Protect the hose from sharp objects and heat.

5. Do not modify this tool. Modifications may reduce the effectiveness of safety measures and

increase the risks to operator.

6. Keep the tool away from your body when it is running. Do not wear loose or ill-fitting clothing;

remove watches and rings.

7. Secure the work with clamps or a vise so both hands are free to operate the tool. Don’t overreach.

Always keep proper footing and balance.

8. Tool can vibrate in use. Vibration or uncomfortable positions over extended periods of time may

be harmful to your hands, arms, or other parts of your body. Discontinue use if you experience

discomfort. Instantly tell your employer and consult a qualified health professional.

9. Air under pressure can cause severe injury. Never direct air at yourself or others. Hose whip can

cause serious injury. Always check for damaged, frayed or loose hoses and fittings, and replace

immediately.

10. Anticipate and be alert for sudden changes in motion during start up and operation of any power

tool.

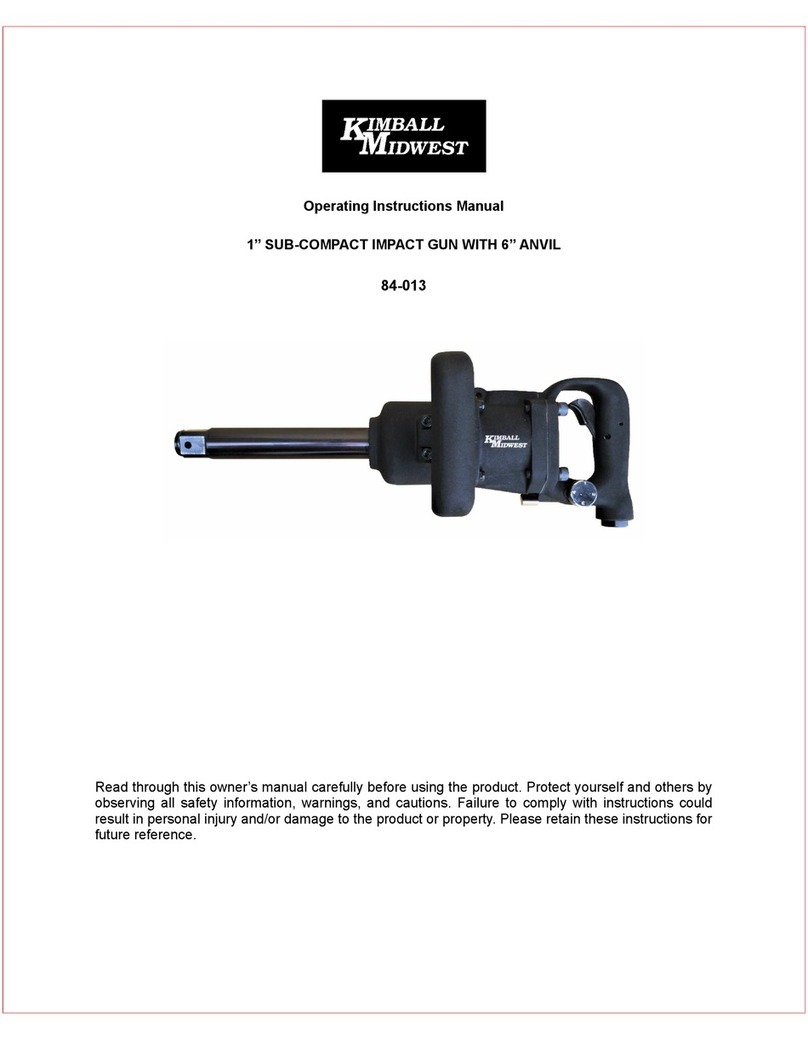

LUBRICATION:

Lubricate the tool daily with a high-quality air tool oil. If no inline oiler is used, run a teaspoon of oil

through the tool. The oil can be added into the tool air inlet or into the hose at the nearest connection

to the air supply, then run the tool.

Oil will discharge through exhaust after lubrication during the first few seconds of operation.

MAINTENANCE:

Other factors outside the tool may cause loss of power. Reduced compressor output, excessive draw

on the air line, moisture or restriction in air lines or the use of hose connections of improper size or

poor condition may reduce the air supply. Grit or gum deposits in the tool may reduce power and may

be corrected by cleaning the air strainer and flushing out the tool with Ultra Guard Extreme Air

Tool Conditioner [K-M No. 80-293 or 80-291] or Power+Air Tool Conditioner [K-M No. 80-769].