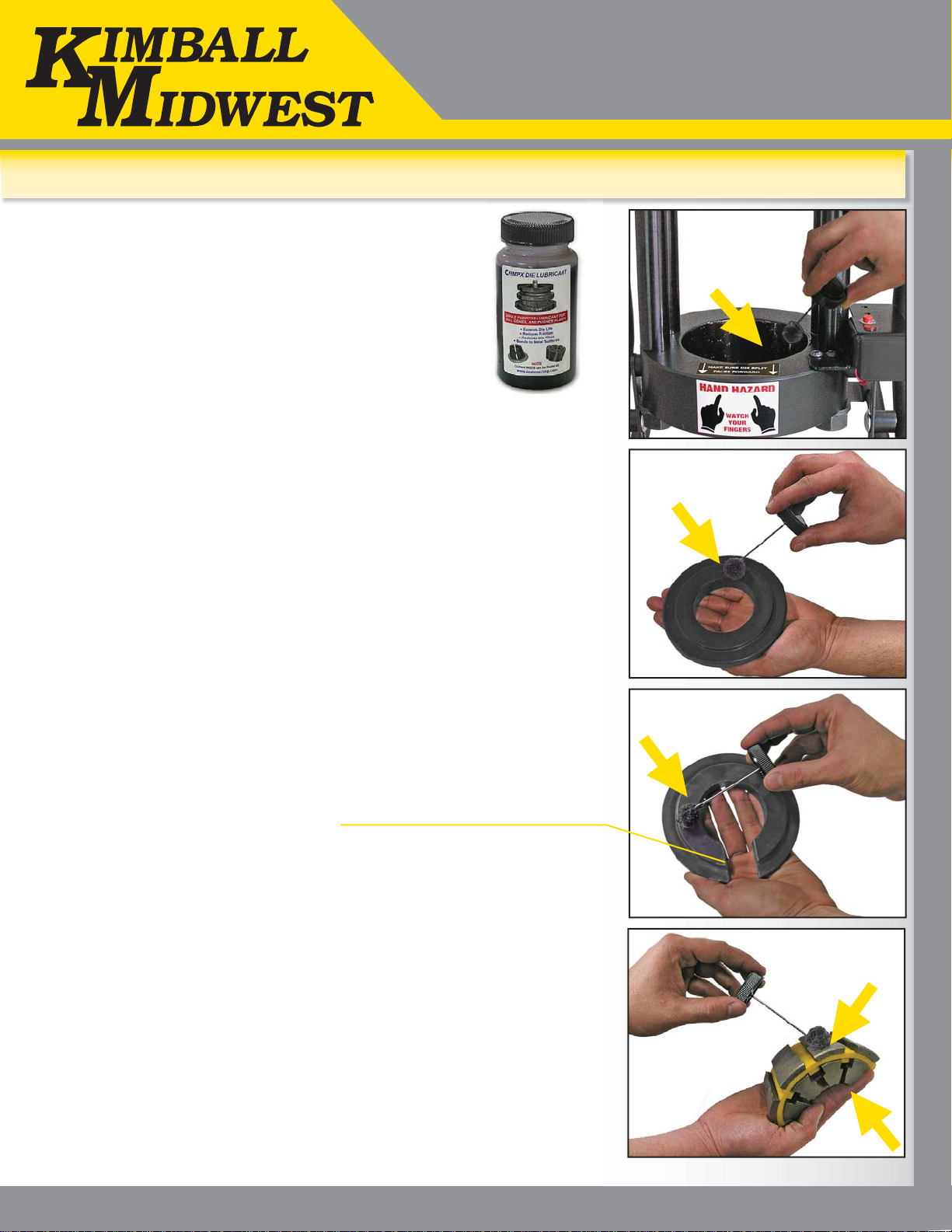

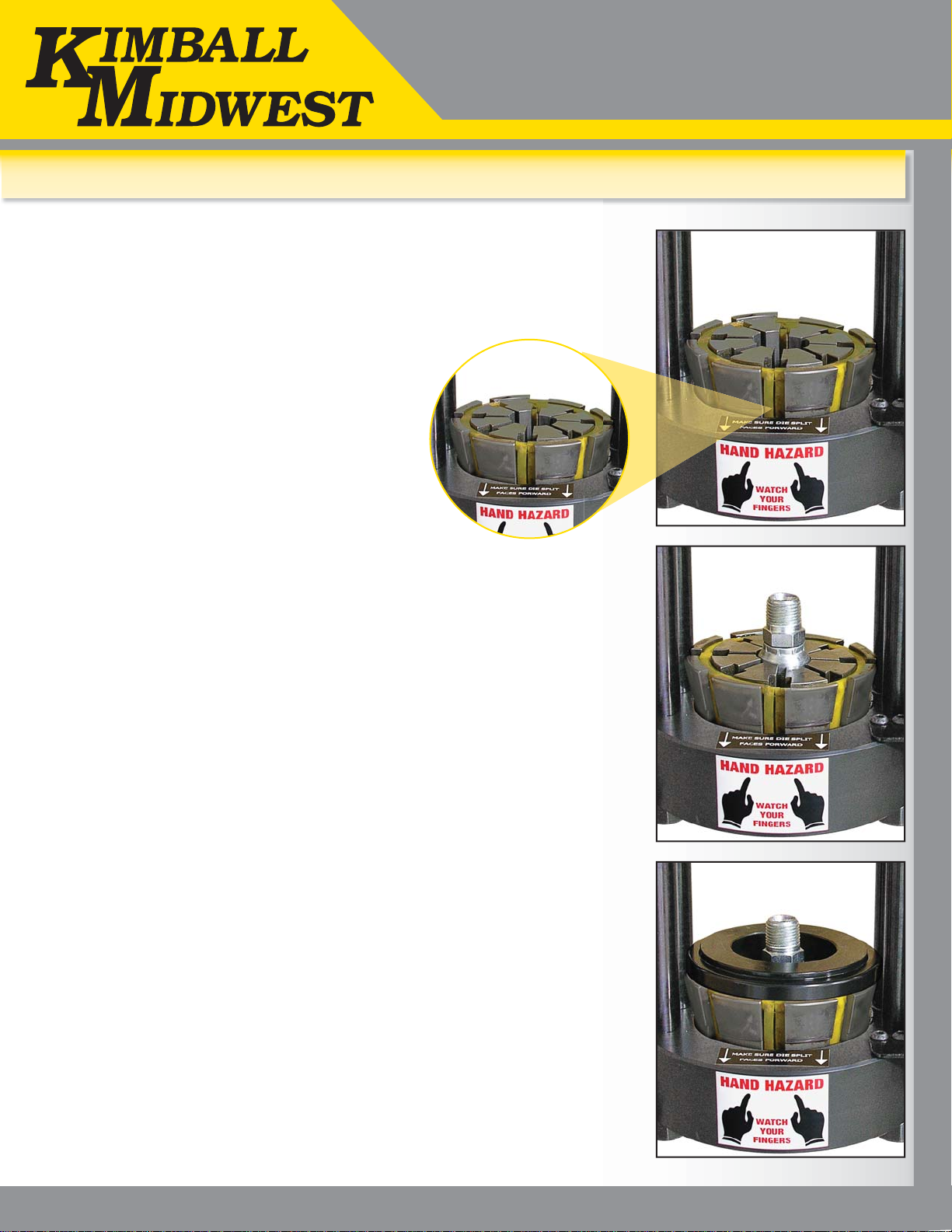

KIMBALL MIDWEST K100 Portable User manual

Other KIMBALL MIDWEST Crimping Tools manuals

KIMBALL MIDWEST

KIMBALL MIDWEST 27-799 User manual

KIMBALL MIDWEST

KIMBALL MIDWEST 82-223 Instruction Manual

KIMBALL MIDWEST

KIMBALL MIDWEST 27-798 Instruction Manual

KIMBALL MIDWEST

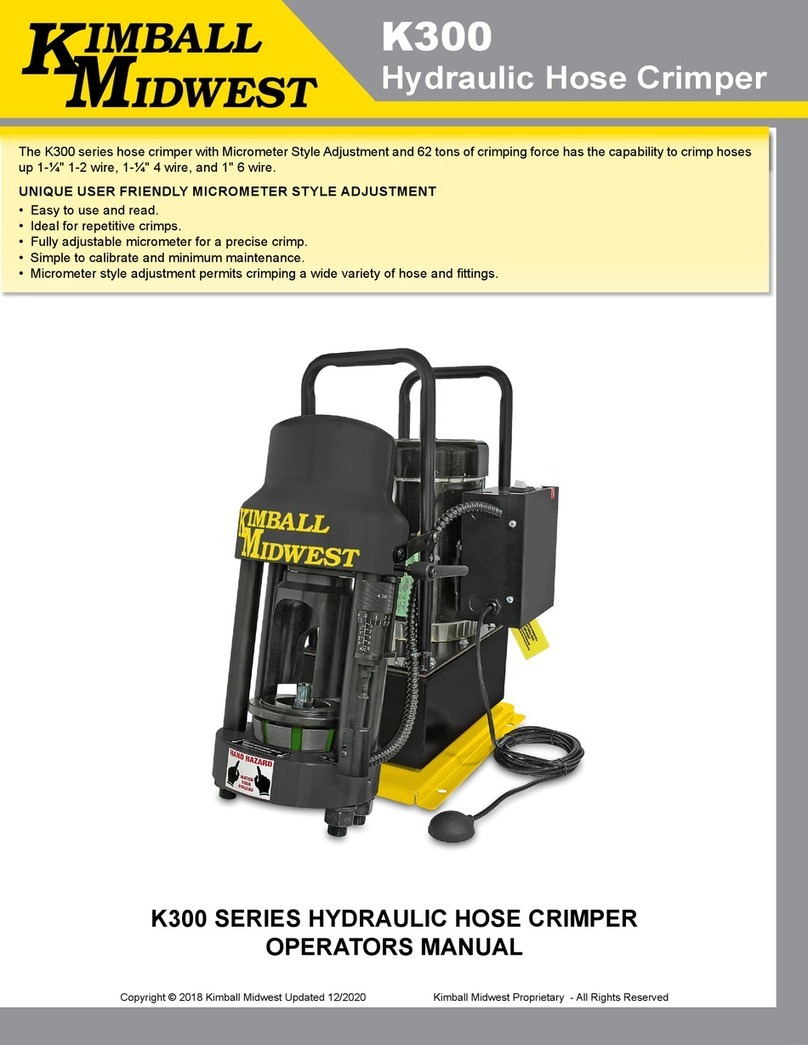

KIMBALL MIDWEST K300 Series User manual

KIMBALL MIDWEST

KIMBALL MIDWEST 84-023 Instruction Manual

KIMBALL MIDWEST

KIMBALL MIDWEST 84-013 Instruction Manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet