HIGH PRESSURE CONTROL VALVEHIGH PRESSURE CONTROL VALVE

Model: R2L ACTUATOR

Installation, Operation & Maintenance Guide

Model: R2L ACTUATOR

Installation, Operation & Maintenance Guide

7

www.kimray.com

1 Installation

If the Actuator has been shipped separately for installation

on a Kimray Valve Body, or if the Actuator was removed

for maintenance, mount the Actuator by following the

instructions presented in this section. Inspect the surface

of the Mounting Yoke and clean the mating valve surface

to remove scale, chips and debris.

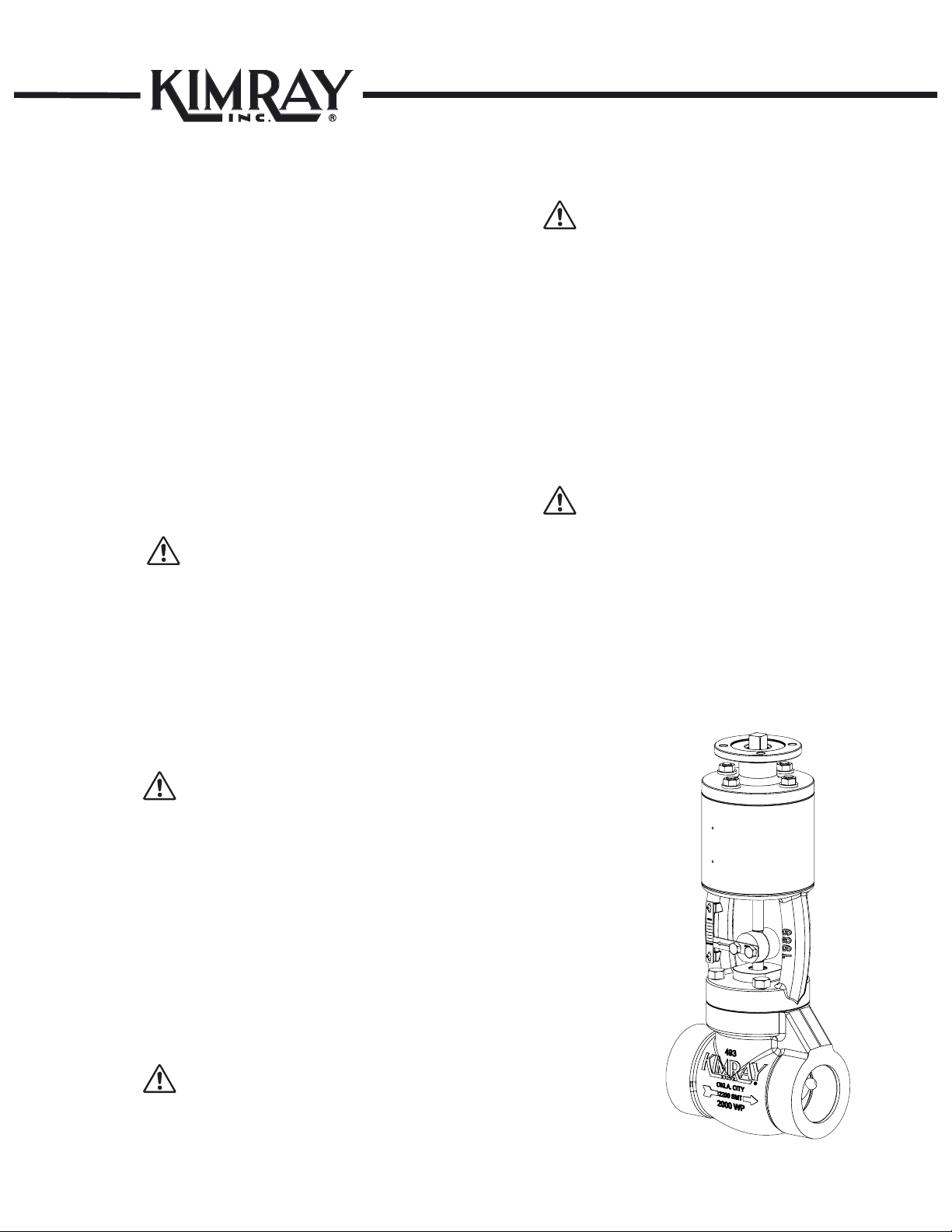

The Kimray R2L is used with Kimray High Pressure

Control Valves such as through or angle body valves. In

the R2L Actuator, the spiral rotation of the Rotary Shaft

by means of a rotary Actuator is translated into linear

motion, opening and closing the valve. The stroke length

is achieved with a 90° rotation of the shaft, clockwise to

close. As the Plug contacts the seat, a series of Springs

become loaded to ensure valve closure in the event of

seat creep or wear.

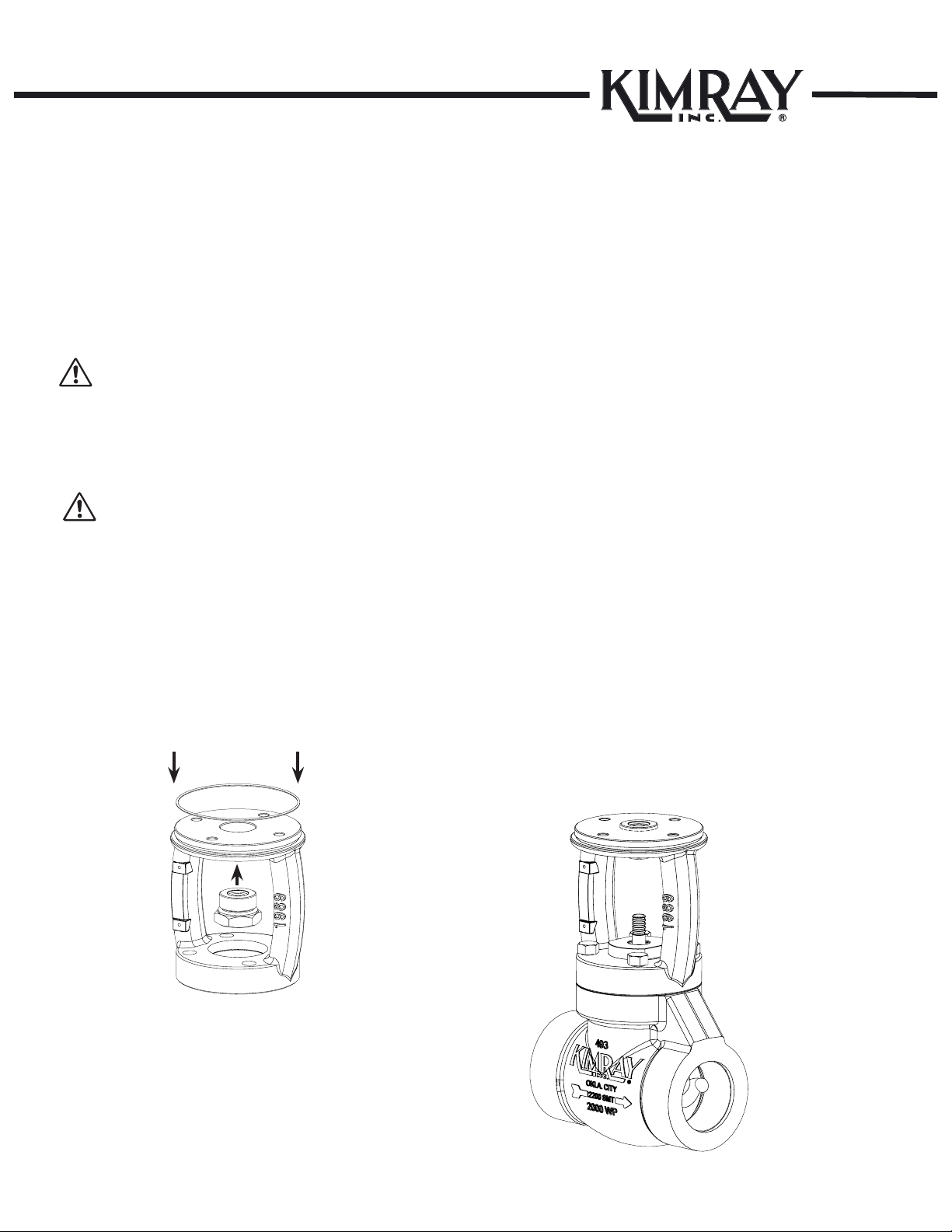

1. Mount the Actuator onto the Valve using supplied bolts

and tighten.

NOTE:

Tighten the bolts in a criss-cross pattern to avoid any miss

alignment. DO NOT OVER TIGHTEN. For 1in. and 2in.

tighten bolts from 25-30 ft/lbs torque.

2. Install Travel Indicator Assembly on Stem and tighten

the bolts in the Coupling Block with a socket. Align

the open or close line on the Indicator Scale with

the Travel Indicator and secure the Indicator Scale by

driving in the u-drive screws. Adjust the Travel

Indicator as needed to ensure it does not catch or

drag against the Indicator Scale.

NOTE:

For the quarter turn Actuator, follow manufacturer

recommendation for the installation and operation notes.

3. Install the valve using good piping practice. For anged

bodies remove the masking sticker from the raised face of

each end connection & use a suitable gasket between the

body and the pipeline anges. For threaded (NPT) bodies,

use TFE Tape or pipe thread sealant on external pipe

threads.

4. Install the valve using good piping practices. For

anged bodies use a suitable gasket between the

body and the pipeline anges. For threaded (NPT)

bodies, use TFE tape or pipe thread sealant on

external pipe threads. Use good practices.

NOTE:

Use good electrical wiring practices and consult with

electrican.

See Fig. 1-1

2Start-up & Test

WARNING:

Before any service, be certain that the valve is fully

isolated and that all pressure upstream and downstream

has been relieved. Use bypass valves or fully shut off

the process. Be sure that any operating or instrument

gas lines have been disconnected. Never assume that

a check valve is fully blocking the downstream line.

Never tighten any tting or the main connections to the

regulator while there is pressure on the line. A leaking

valve indicates that service is required. Failure to take the

valve out of service immediately may create a hazardous

condition.

Verify all pressure connections are tight before

pressurizing the system.

NOTE:

When a gasket seat is disturbed during disassembly a

new gasket should be installed during re-assembly to

ensure proper sealing.

Repair kits are available. See Section E1 of catalog or

the packing slip enclosed with each valve for the correct

repair kit numbers.

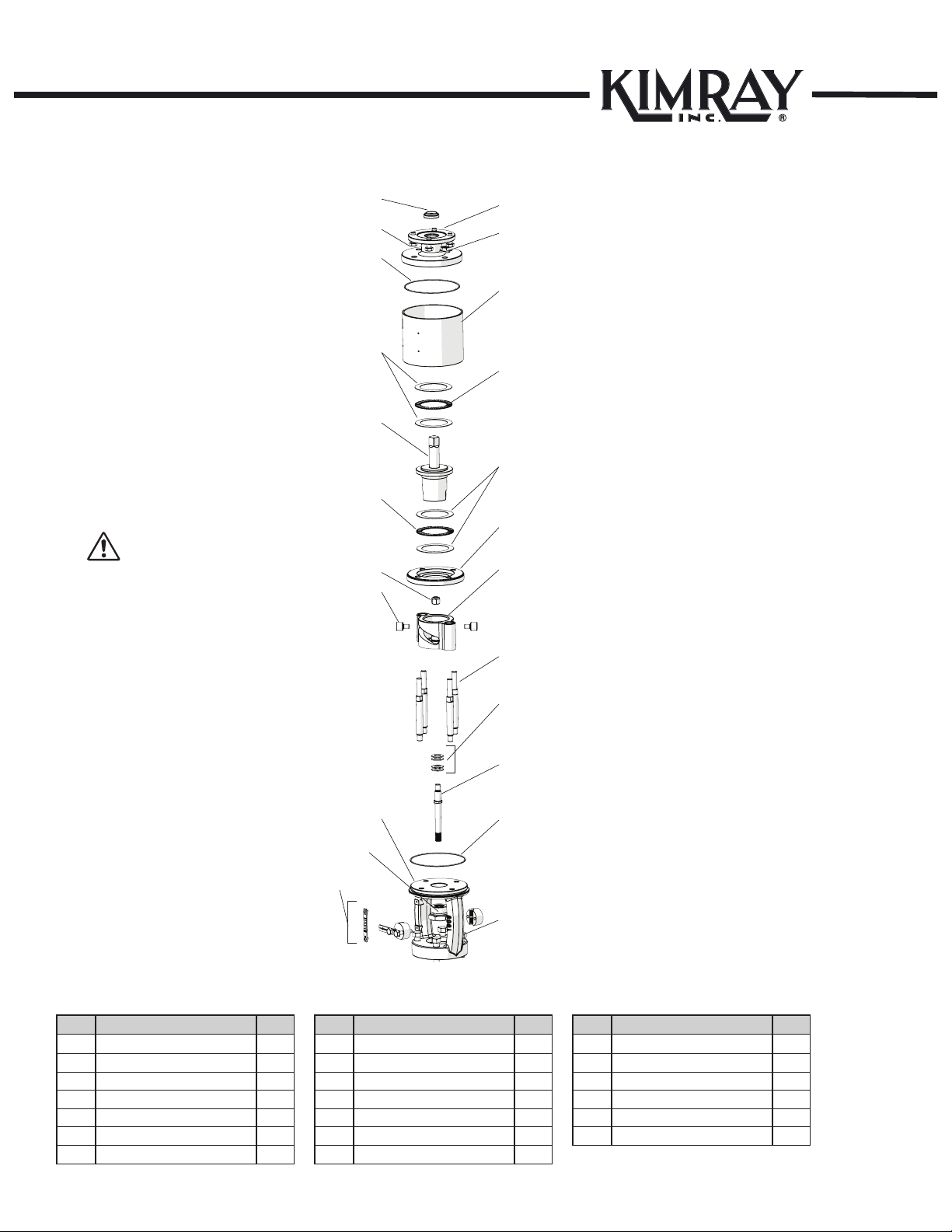

Fig. 1-1