2.

Table of Contents

1. Disclaimer................................................................................................................. 1

2. Table of Contents...................................................................................................... 2

3. List of Figures ...........................................................................................................3

4. Certification Details...................................................................................................5

5. Common System Features ....................................................................................... 5

5.1.

Torque Specifications....................................................................................................................................5

5.2.

Kinetic Product Configurations......................................................................................................................6

5.3.

Components..................................................................................................................................................7

6. Bonding Path .......................................................................................................... 12

6.1.

Traditional Grounding Path.........................................................................................................................12

6.2.

Groundhog Rail Grounding Path.................................................................................................................15

6.3.

Hat Rail Grounding Path.............................................................................................................................16

6.4.

Grounding Path in Bifacial Rail....................................................................................................................17

6.5.

Grounding Path in Ridge Rail......................................................................................................................19

6.6.

Joiners........................................................................................................................................................20

6.7.

Thermal Break............................................................................................................................................22

6.8.

Grounding...................................................................................................................................................22

6.9.

Bonding and Grounding Devices ................................................................................................................24

6.10.

Removing Modules from an Array...............................................................................................................31

7. List of Compatible Modules..................................................................................... 32

8. Required Maintenance............................................................................................ 32

9. Pitched Roof Installation Instructions ...................................................................... 32

9.1.

Layout Considerations.................................................................................................................................32

9.2.

Install Roof Mounts.....................................................................................................................................35

9.3.

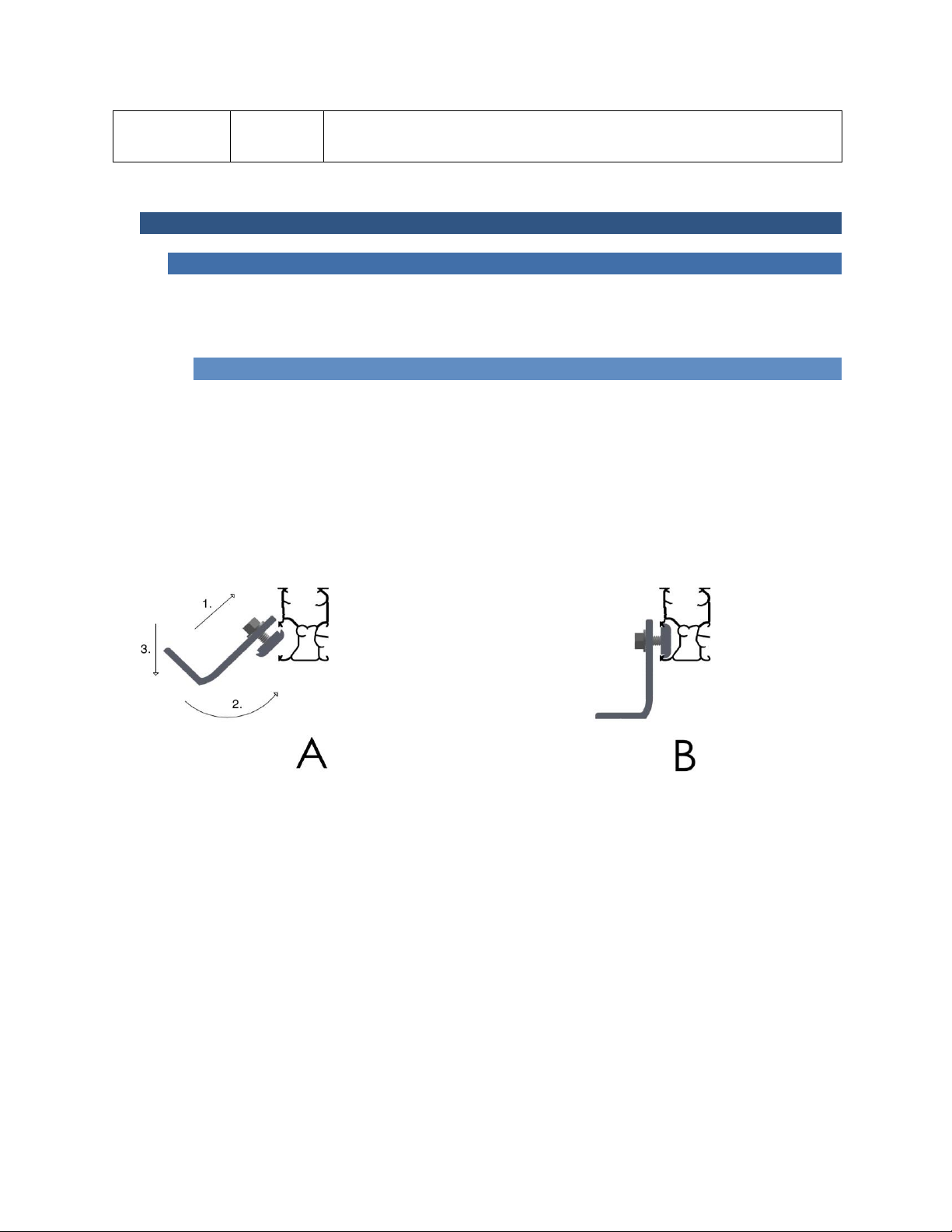

L-Brackets / Rails........................................................................................................................................48

9.4.

Bear Clamp…………………………………………………………………………………………………………………49

9.5.

Rail Joiners.................................................................................................................................................49

9.6.

Awning Mounts ...........................................................................................................................................49

9.7.

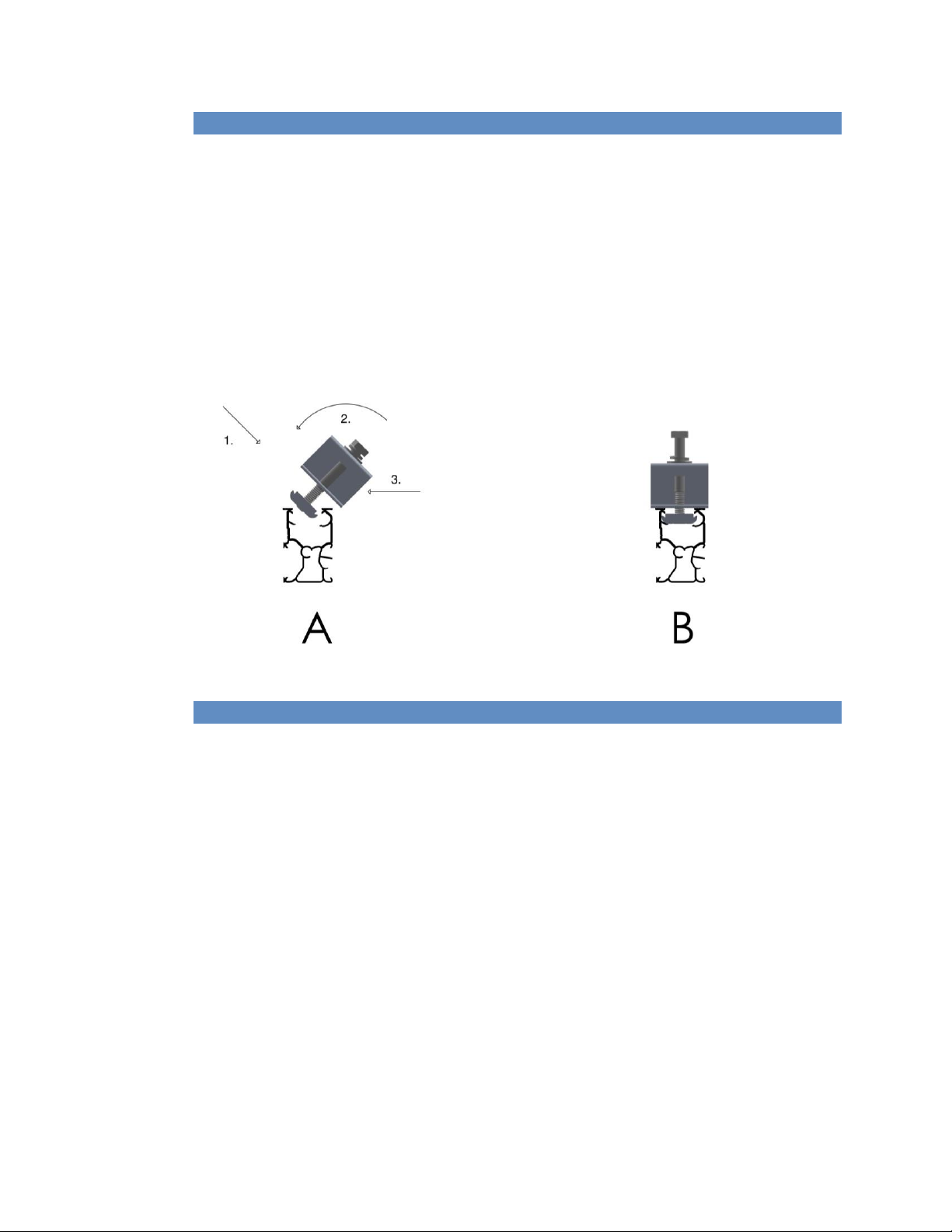

Micro Inverters............................................................................................................................................50

9.8.

Mount Solar Modules..................................................................................................................................51

9.9.

Wire Management.......................................................................................................................................52

10. Venture Rail System............................................................................................ 53

10.1.

O-Ring Cord Sealing Channel.....................................................................................................................53

10.2.

Install Rails .................................................................................................................................................53

10.3.

Mounting Modules.......................................................................................................................................53

10.4.

Wire Management.......................................................................................................................................54

10.5.

Micro-Inverter Mounts.................................................................................................................................55