INSTRUCTIONS

VIPER2HIGH SPEED HANDPIECE

INSTALLATION AND OPERATION

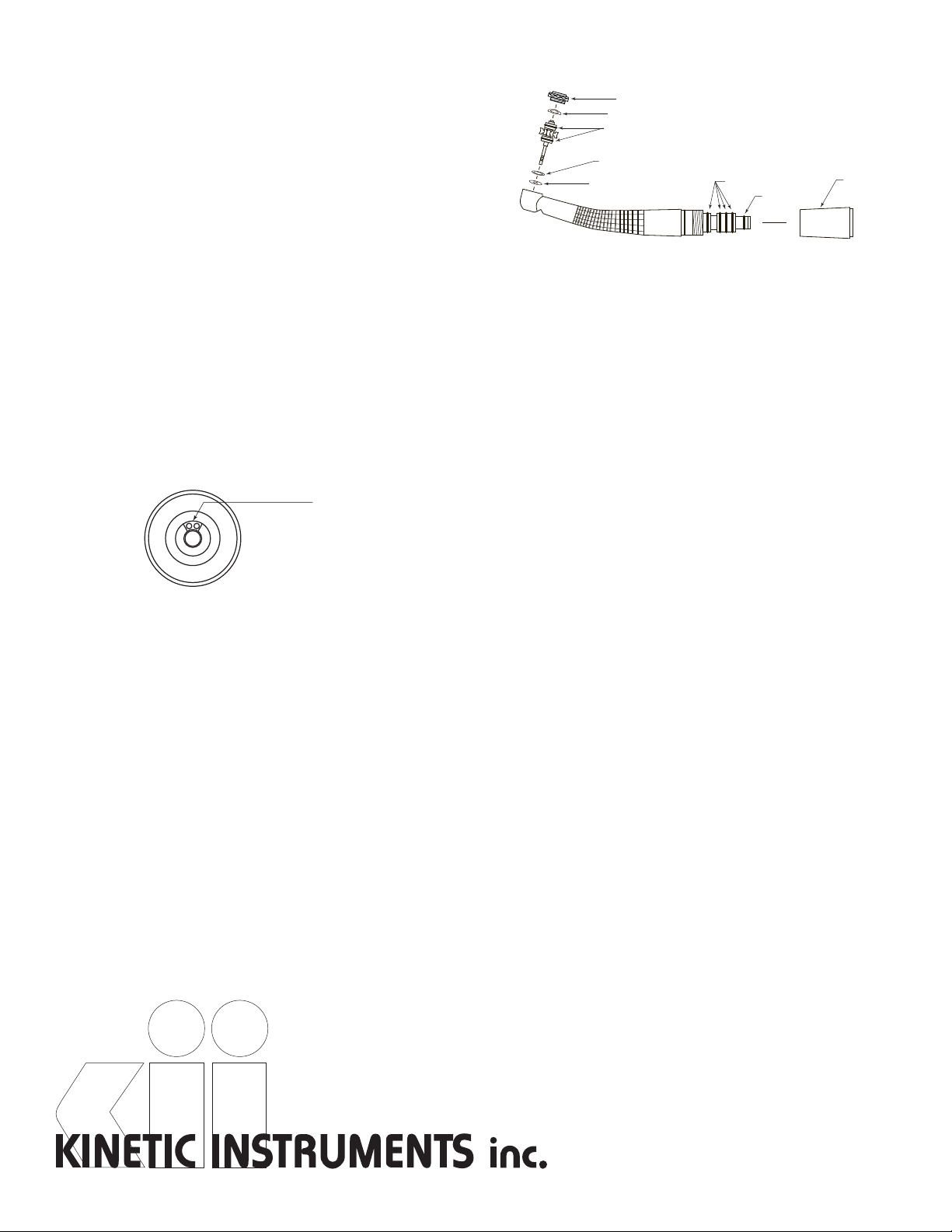

The Viper2360 swivel handpiece is equipped with a quick connect feature to

facilitate fast connection of additional Kinetic Viper2360 handpieces as well as

easy lubrication and infection control procedures. To disassemble the

handpiece at the 360 quick coupling, simply pull the connecting ring towards the

tubing assembly. To reassemble, seat the handpiece onto the coupling until the

connecting ring automatically locks the handpiece in place.

IMPORTANT FOR SAFETY!

Never pull the connecting ring while the handpiece is turning to avoid the

danger of the handpiece being forcibly disengaged by the air pressure. Before

installing the handpiece, clean and lubricate as explained under

MAINTENANCEAND SERVICING procedures.

Before connecting the handpiece to the light source illumination system tubing,

install a Kinetic swivel lamp module (as shown) into the receptacle on the end

of the tubing. Be certain to align electrical pins to prevent breakage.

Connect the handpiece to the tubing being careful to align all air and water

tubes.

For maximum performance and bearing life, the Viper2360 handpiece should

be operated with clean, filtered, moisture-free air at a pressure of 38-43 psi as

measured at the handpiece coupling.

IMPORTANT OPERATING INFORMATION

1.Bur changing technique may be different than similar handpieces ... follow

instructions to avoid turbine damage.

2.Do not operate the handpiece at pressures in excess of 45 psi to avoid

premature turbine failure.

3.Never pull the 360 Quick Coupling connecting ring while the handpiece

is operating.

4.Never operate the handpiece, even for an instant, without a bur installed to

avoid chuck damage.

5.Avoid prolonged "no load" conditions.

6.When switching handpiece delivery hoses, insure that the recommended air

pressure is not exceeded.

7.Lubricate the handpiece at least twice a day.

8.Never use short shank burs.

CHANGING BUR

The Viper2chucking mechanism is designed to always be operated with a bur

installed. To prevent damage to the handpiece and the danger of an ejected

rotating bur, NEVER depress the PUSH-LOK while the handpiece is rotating.

Aflat wound spring is used to lock the bur jaws in place. When removing a bur,

be sure to depress the push button all the way down. A click may be felt as the

spring is compressed. This is especially important since, under certain heavy

cutting situations, the bur may afterwards seem to be "jammed" in the

handpiece. This is not a defect in the chuck mechanism but is a result of the

increased locking action of the bur jaws under heavy pressure.

The chuck is designed to become tighter as greater pressure is applied,

preventing bur slippage. If this situation is encountered, extra force can be

applied to the push button.

CHUCK MAINTENANCE

In general, the chuck mechanism is not subject to wear and should easily

outlast the turbine and bearing assemblies. However, inadvertent introduction of

oral cavity fluids, chemical disinfecting liquids, or other materials into the chuck

mechanism may possibly produce residues which could easily interfere with the

chucking action. If this situation is encountered and cannot be rectified by

cleaning, the turbine should be returned to the factory for disassembly, cleaning

and possibly a complete rebuilding.

LAMP CHANGING

Using the quick disconnect, remove the handpiece. Holding the smooth front of

the coupling, unscrew the tubing nut and separate the coupling from the tubing.

Unplug the burned out lamp and replace with a new Viper2360 swivel lamp

while carefully aligning the electrical pins. Replace the coupling onto the tubing

assembly and reconnect the handpiece.

INFECTION CONTROL PROCEDURES

AUTOCLAVE: To use an autoclave as an effective means of infection control

requires an autoclave cycle after each patient. Although the Viper2360

handplece is fully autoclavable, the autoclave environment is hostile to any

handpiece and will result in slow physical and operational degradation. Less

frequent autoclaving is not recommended since this would compromise

infection control. If autoclaving is the preferred method, the following directions

should be applied to assure maximum longevity:

1.Thoroughly clean handpiece using brush and detergent.

2.Rinse completely.

3.Allow handpiece to dry and then lubricate (optional).

4.Remove all excess lubricant.

DISINFECTANT SOLUTIONS: Various bactericidal and virucidal solutions are

available which provide high level disinfection and sterilization. In addition to

following the manufacturer's recommendations for use, it is essential to develop

a procedure to remove the solutions after disinfecting. The residues that remain

after evaporation of the solution can easily interfere with all mechanisms in the

handpiece. Do not allow the disinfectant solution to dry on the handpiece. If the

procedures suggest drying, modify them by soaking gauze in the solution and

leave it in contact with the handpiece for the required time duration.

Immediately after disinfecting, wash the handpiece thoroughly with tap water or

sterile water. Complete immersion in water will not harm the handpiece. After

washing, shake the handpiece to remove excess water, blow dry with Triplex

syringe and lubricate.

CHEMICLAVE: Chemiclave may be used for infection control as long as there

are not high levels of residue left on the handpiece after the cycle. Be certain

the chemiclave solution used is compatible with those materials found in high

speed handpieces. A chemiclave is essentially an autoclave and therefore

follow all considerations underAUTOCLAVE.

DRY HEAT STERILIZATION: Do not use dry heat sterilizers for handpieces.

TURBINE CARTRIDGE REPLACEMENT

Remove bur from handpiece. Remove handpiece head back end cap using the

cap wrench as illustrated. Push out the turbine cartridge assembly from the

head cavity using a bur or bur blank if necessary.

Note: Although the assembly drawing shows the location of the dust sealing

washer, dust washer retainer and two turbine cartridge o-rings, it is not

recommended that these parts be replaced without prior experience. Therefore,

do not attempt to remove these parts. If unlikely damage has occurred, consult

the factory for further instructions.

Handpiece

Quick

Coupling

Hose

Nut

Lamp

Module

Connecting

Ring

2.