Positioning water filtration system and

water connection:

Water filter should be mounted upright on a vertical

surface without obstructions.

– Locate an installation location that is near the

equipment it will be supplying with water. Ensure

the location is clear from possible damage from

day-to-day operations.

– Ensure there is a minimum of 4 inches of clearance

below filter cartridge to enable filter change-outs

as needed.

– Turn o water supply and ensure faucets are

turned on or open. This is to remove pressure

from the system.

– Cut inlet and outlet water supply lines.

NOTE: If hard copper plumbing is present, use only

lead-free solder and protect filter housing from

heat. Do not solder within 12" of plastic parts.

– Remove existing filtration system if present.

Terminate both ends of plumbing with

appropriate fittings.

– Insert the appropriate plumbing connection

fittings into the filter head. It is recommended to

use ⅜" fittings or larger to allow for optimal

performance.

– Do not over tighten fittings into plastic parts!

Warranty will be voided if parts are cracked and/or

broken due to misuse and/or over tightening!

Connect water filter inlet to COLD WATER SUPPLY

ONLY. Use approved flexible beverage tubing

where possible with correct sized tube clamps.

If hard plumbing is necessary, then use only lead-free

solder and protect filter housing from excessive

heat. Do not solder within 12" of plastic parts.

From outlet of water filter use no less than ¼" ID tub-

ing to all specified equipment. Teeing the tubing should

be done appropriately, for example ½" x ½" x ½".

Mounting

1. Measure mounting holes of filter system

and mark hole locations on wall.

a. Ensure marks are level. Drill holes for

anchors, if required. Anchors must be properly

sized to allow for the wet weight of the

filter system.

b. Secure backplate to the wall.

Connect Plumbing

Connect supply line to filter system inlet and connect

outlet fitting to existing plumbing.

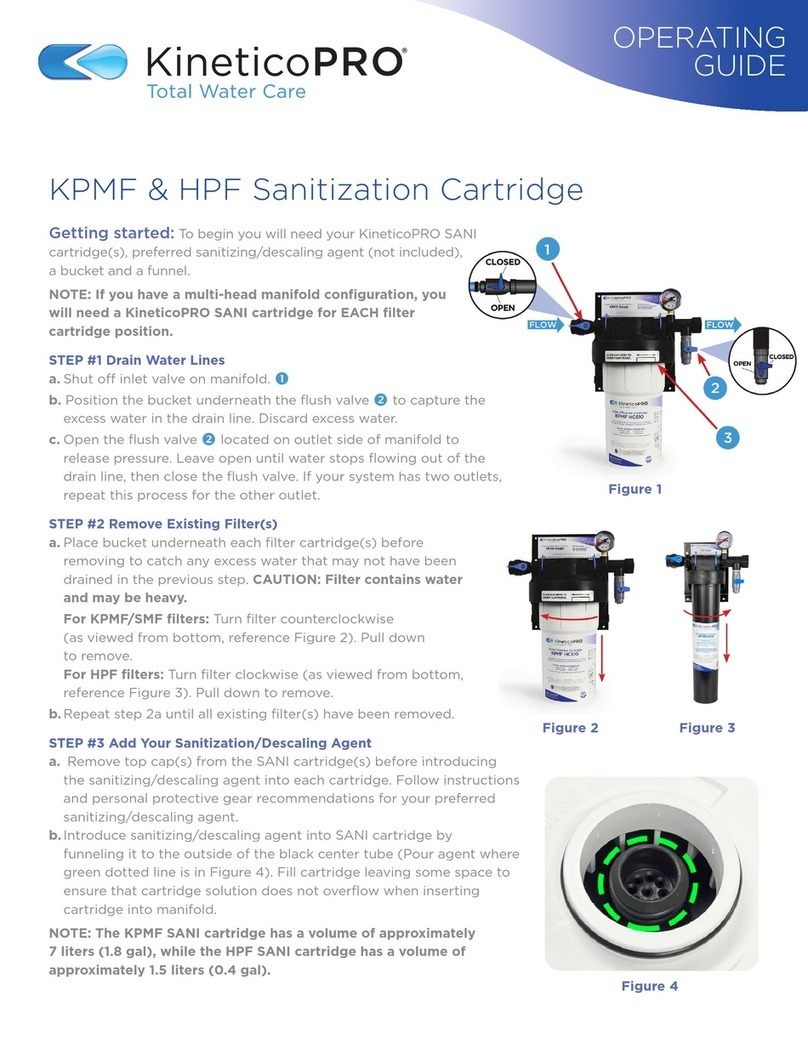

Figure A

Install Cartridge

1. Generously lubricate outer O-ring using food

grade lubrication provided.

2. Align cartridge tabs as indicated on head and

insert cartridge. Push upwards and twist to lock

into place.

Initializing Water Filter

1. Turn on water at the source.

2. Flush the system by flowing water through the

flush valve to a drain for 5 minutes.

3. Purge all air from the plumbing system by

opening a water valve at the point of use for

approximately 1 minute, or until no air found

in lines and water flowing freely.

4. System is now operational. Close faucet.

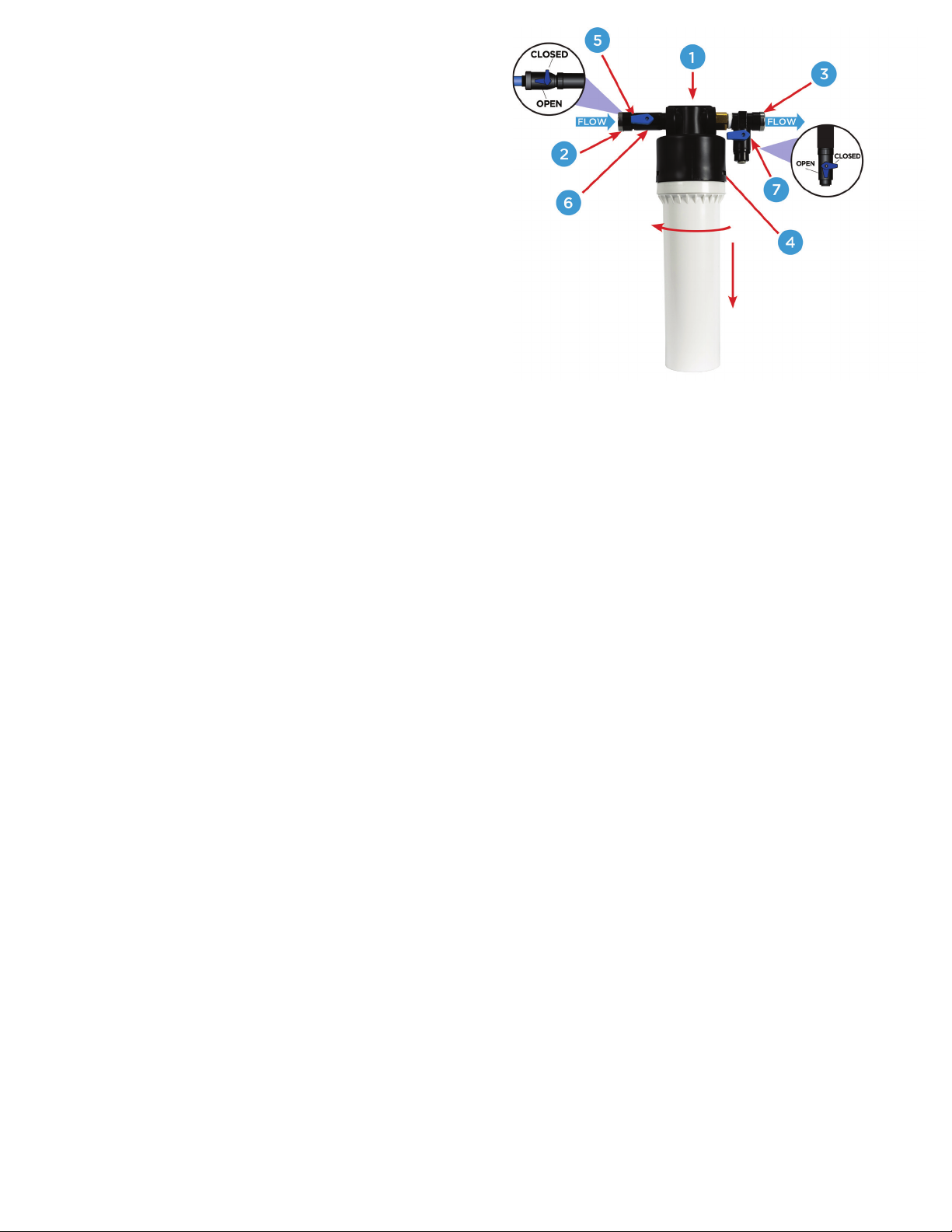

Reverse Flow:

As shipped from the factory, flow is from left to

right. To reverse the flow, follow these steps:

1. Unscrew 2 screws located on top of the head.

2. Rotate head upwards until it disengages from

bracket.

3. Spin head 180 degrees.

4. Reengage head into bracket and rotate downwards

(label will now be on the back of the head, facing

the wall).

5. Reinsert the 2 screws on top of the head.

Cartridge Change Schedule

1. When the line pressure downstream of the filter

housing drops to 30 psi or below during system

operation, the cartridge(s) needs to be replaced.

Occasional dips below 30 psi and back are normal.

2. See filter head for replacement cartridge

ordering information.