SPECIFIC SAFETY INSTRUCTIONS,

SPECIFICATIONS & TABLE OF CONTENTS

1. ALWAYS USE A GUARD.

Always use a guard, splitter and anti-kickback fingers on all

“thru-sawing” operations. Thru-sawing operations are those

when the blade cuts completely through the workpiece as in

ripping or crosscutting.

2. ALWAYS HOLD THE WORK.

Always hold the work firmly against the miter gauge or fence.

3. ALWAYS USE A PUSH STICK.

For ripping narrow stock. Refer to ripping applications in

instruction manual where push sticks are covered in detail.

4. NEVER.

Never perform any operations “free-hand” which means using

your hands to support or guide the workpiece. Always use

either the fence or the miter gauge to position and guide the

workpiece.

5. NEVER.

Never stand or have any part of your body in line with the path

of the saw blade.

6. NEVER REACH BEHIND.

Never reach behind or over the cutting tool with either hand for

any reason.

7. MOVE THE RIP FENCE.

Move the rip fence out of the way when cross cutting.

8. WHEN CUTTING MOULDINGS.

Never run the stock between the fence and the moulding

cutterhead. Refer to moulding applications in the manual for

details.

9. DIRECTION OF FEED.

Feed work into the blade or cutter against the direction or

rotation of the blade or cutter.

10. NEVER.

Never use the fence as a cut-off gauge when you are cross

cutting.

11. NEVER.

Never attempt to free a stalled saw blade without first turning

the saw OFF.

12. PROVIDE ADEQUATE SUPPORT.

To the rear and sides of the table saw for wide or long

workpieces.

13. AVOID KICKBACKS.

Avoid kickbacks (work thrown back towards you) by keeping

the blade sharp, by keeping the rip fence parallel to the saw

blade, by keeping the splitter and anti-kickback fingers and

guard in place and operating, by nor releasing work before it is

pushed all the way past the saw blade, and by not ripping work

that is twisted or warped or does not have a straight edge to

guide along the fence.

14. AVOID AWKWARD OPERATIONS.

Avoid awkward operations and hand positions where a

sudden slip could cause your hand to move into the cutting

tool.

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 HP

Amps/Voltage . . . . . . . . . . . . . . . . . . .18A @110V, 9A @ 220V

Pre-wired at . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220V

Table size with extensions . . . . . . . . . . . . . . . . . . . . . .40” x 27”

Miter angle . . . . . . . . . . . . . . . . . . . . . . . . . . . .600Left & Right

Bevel angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .900to 450

Blade size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10”

Maximum cutting depth 90 bevel . . . . . . . . . . . . . . . . . . .3-1/2”

Maximum cutting depth 45 bevel . . . . . . . . . . . . . . . . . . .2-1/8”

Arbor speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4500 R.P.M.

Arbor diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5/8”

SPECIFICATIONS

Warranty ..................................................................................................................................................................................................1

General safety instructions ......................................................................................................................................................................2

Specific safety instructions, Specifications, Table of contents..................................................................................................................3

Assembly ..............................................................................................................................................................................................4-7

Electrical connections ..............................................................................................................................................................................8

Adjustments ..........................................................................................................................................................................................8-9

Operations ........................................................................................................................................................................................10-12

Troubleshooting ......................................................................................................................................................................................13

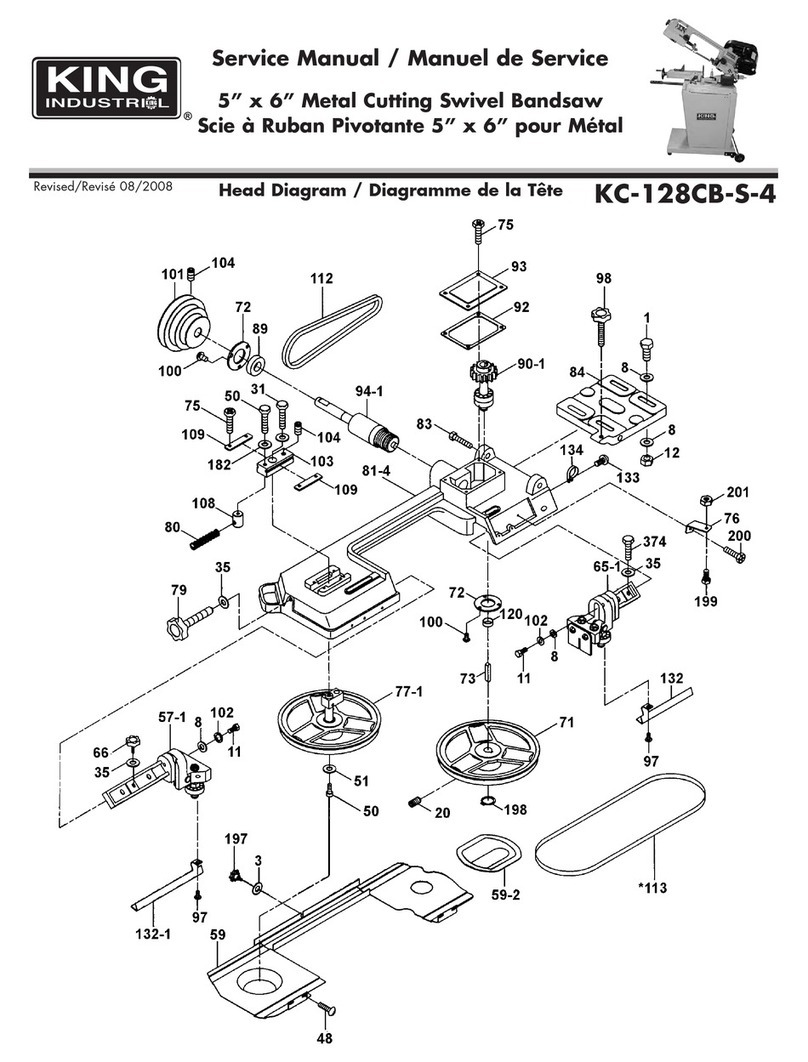

Parts diagrams ..................................................................................................................................................................................14-16

Parts lists ..........................................................................................................................................................................................16-17

TABLE OF CONTENTS